Loading 3D model...

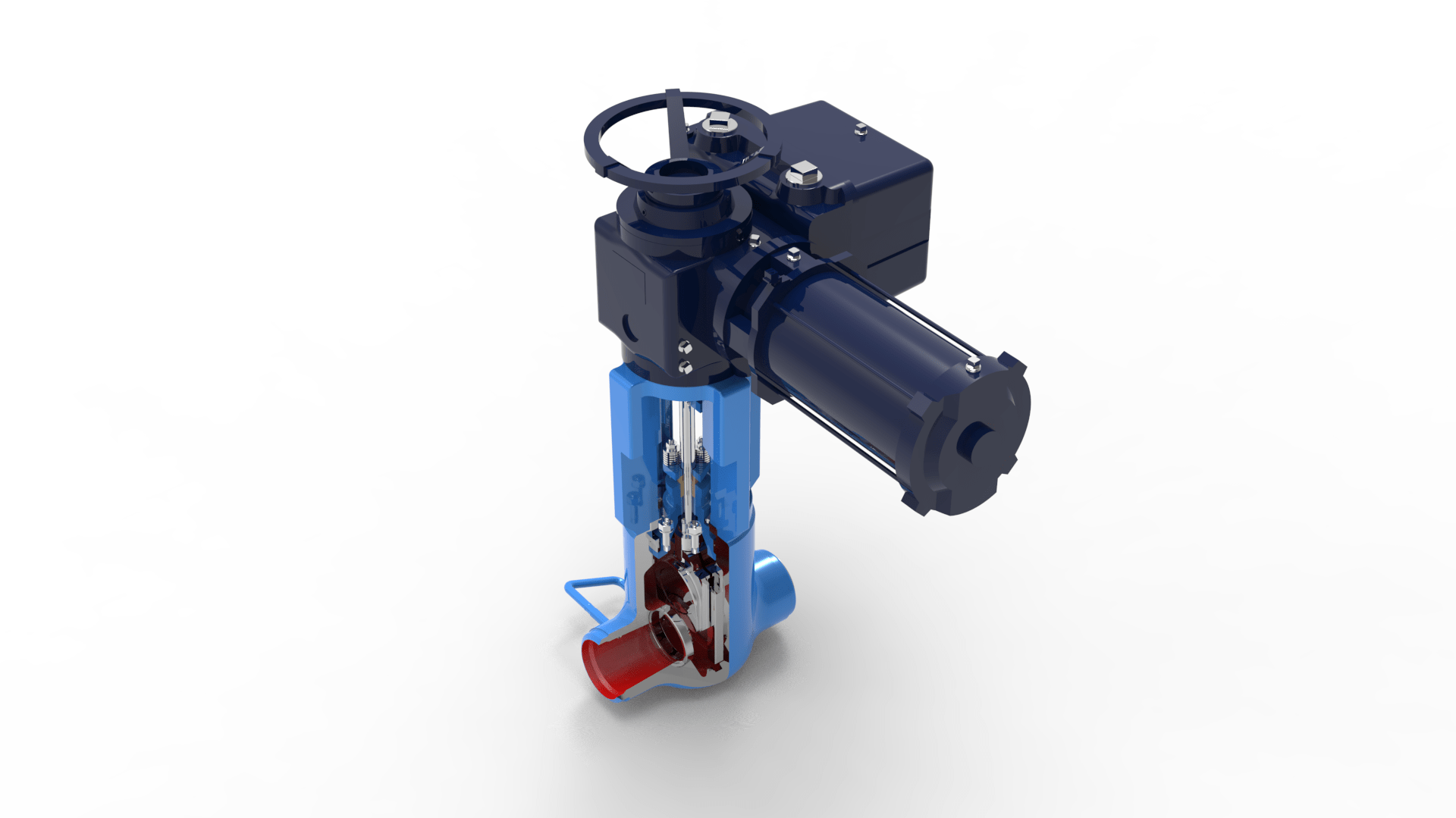

Hopkinsons®

Gate Valves Flexi Wedge Design

The outstanding feature of the parallel slide design is that of maintaining fluid-tightness without the aid of wedging action. No mechanical stress is exerted between the discs, and there are no problems associated with cool-down of the fluid.

VENTURI DESIGN

-

The Venturi design is used when a slightly higher pressure drop is acceptable. The well established principle of fluid flow through a Venturi is used in order to minimize pressure drop.

-

Venturi valves incorporate the design feature of an eye follower. In the fully open position the eye follower bridges the gap between the seats thus giving a smooth flow path and completing the Venturi profile.

APPLICATIONS

-

General purpose stop valve

-

Main steam and feedwater isolation

-

Boiler circulating pump isolation

-

The basic design is also incorporated in valves for other duties such as: Feedwater heater protection; Feed pump leak-off; Nuclear Applications (ASME Section III, Class 1, 2 & 3); Oil & Gas applications upstream, midstream, and downstream

MATERIALS

-

Carbon Steel

-

Alloy Steel

-

Stainless Steel

-

Bronze

KEY FEATURES & BENEFITS

-

Position indication

-

Bonnet overpressure protection

-

Seal weld (bolted bonnet)

-

Canopy seal (pressure seal)

-

Integral bypass arrangements & option

-

Instrumented stem

-

Gate valves – Flexi wedge design

-

Designed for containment isolation duties

DESIGN STANDARDS

-

ASME B16.34

-

Alternatively, valves can be supplied to other national standards.

-

ASME section IIIRCC-M.

DESIGN RATINGS

-

ASME Class 150 to 2500

TEMPERATURE RANGE

-

-29°C - 620°C (-20°F - 1150°F)

PRESSURE CLASS & POWER RATING

-

80 - 600 mm (3 - 24 inches)