Loading 3D model...

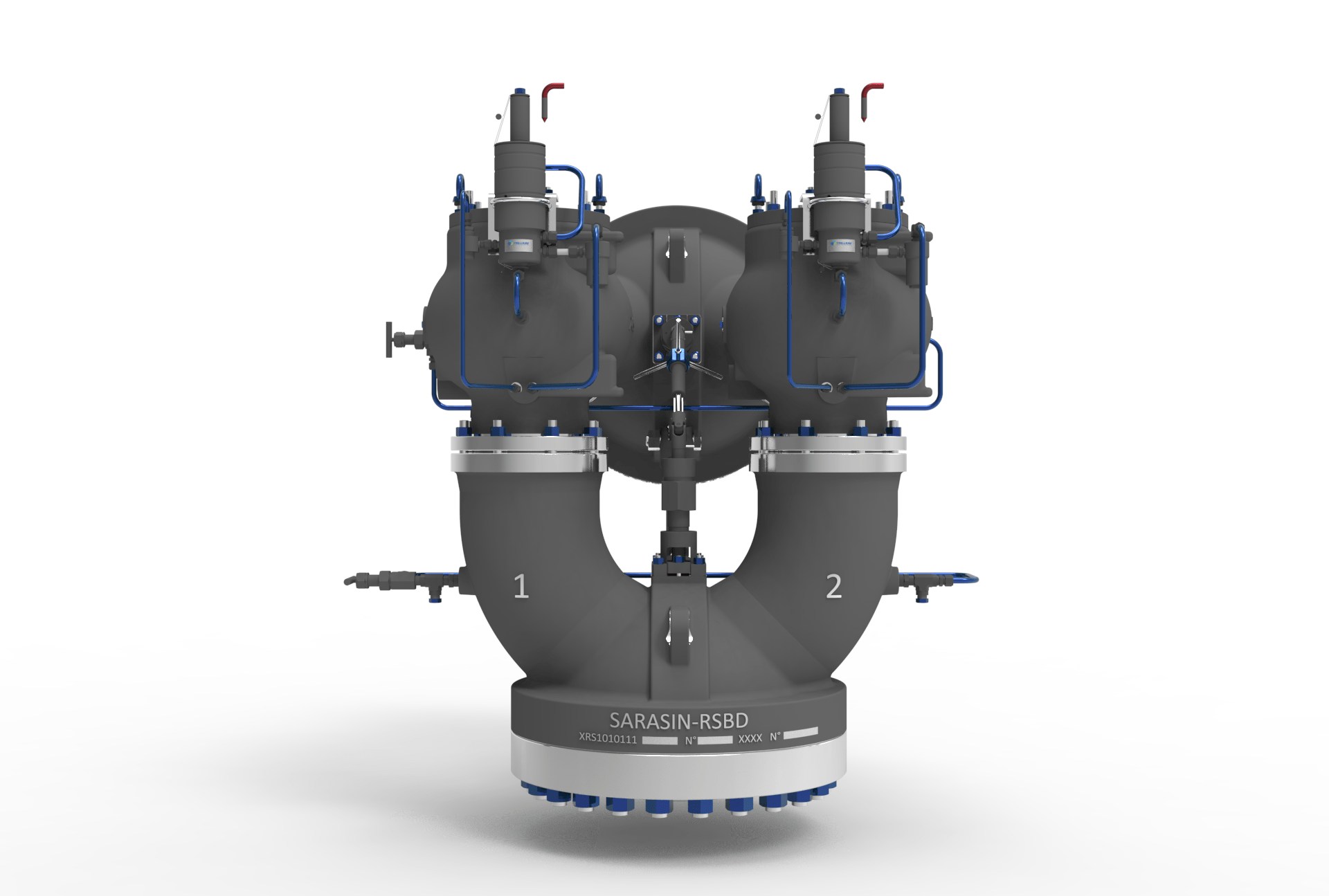

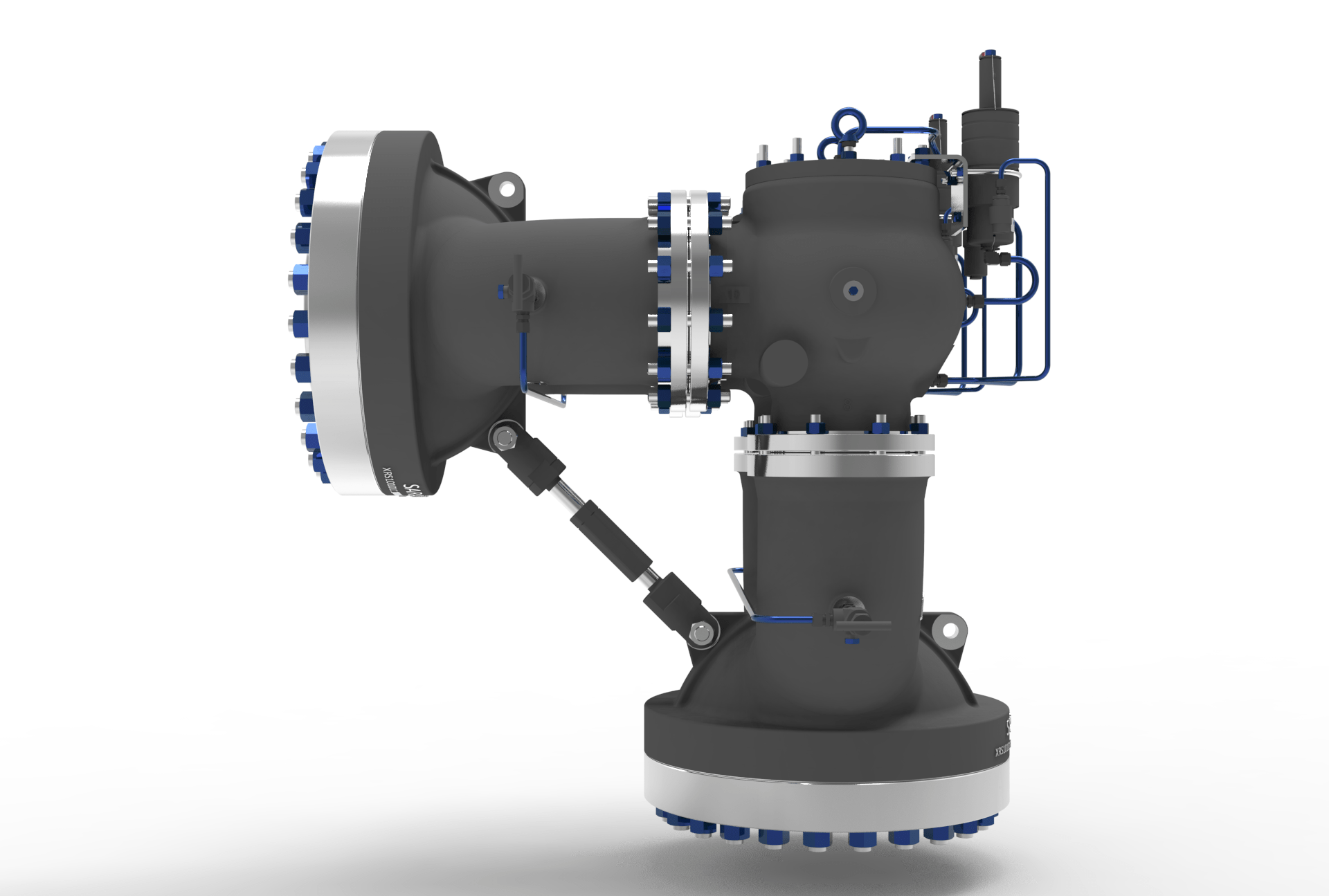

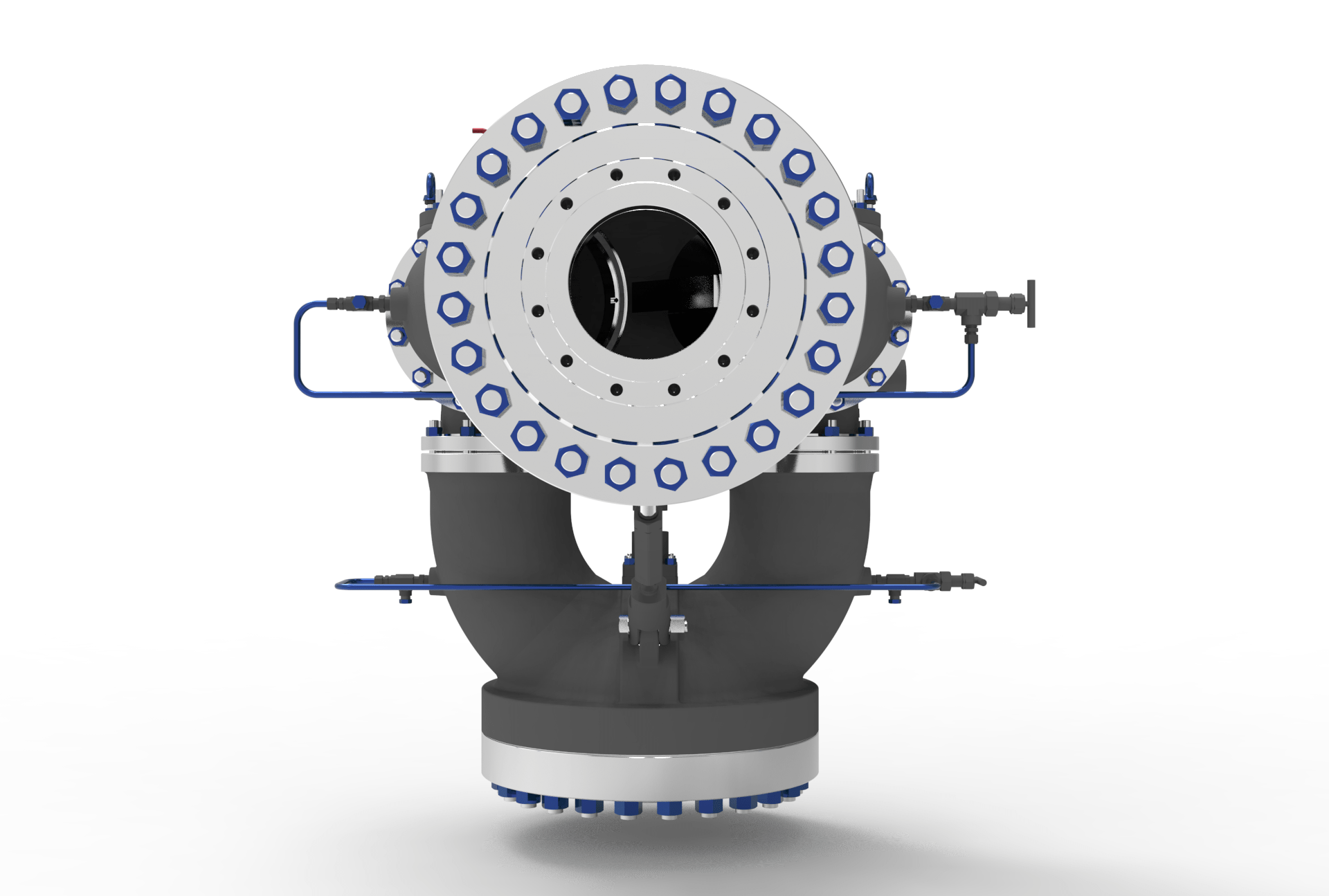

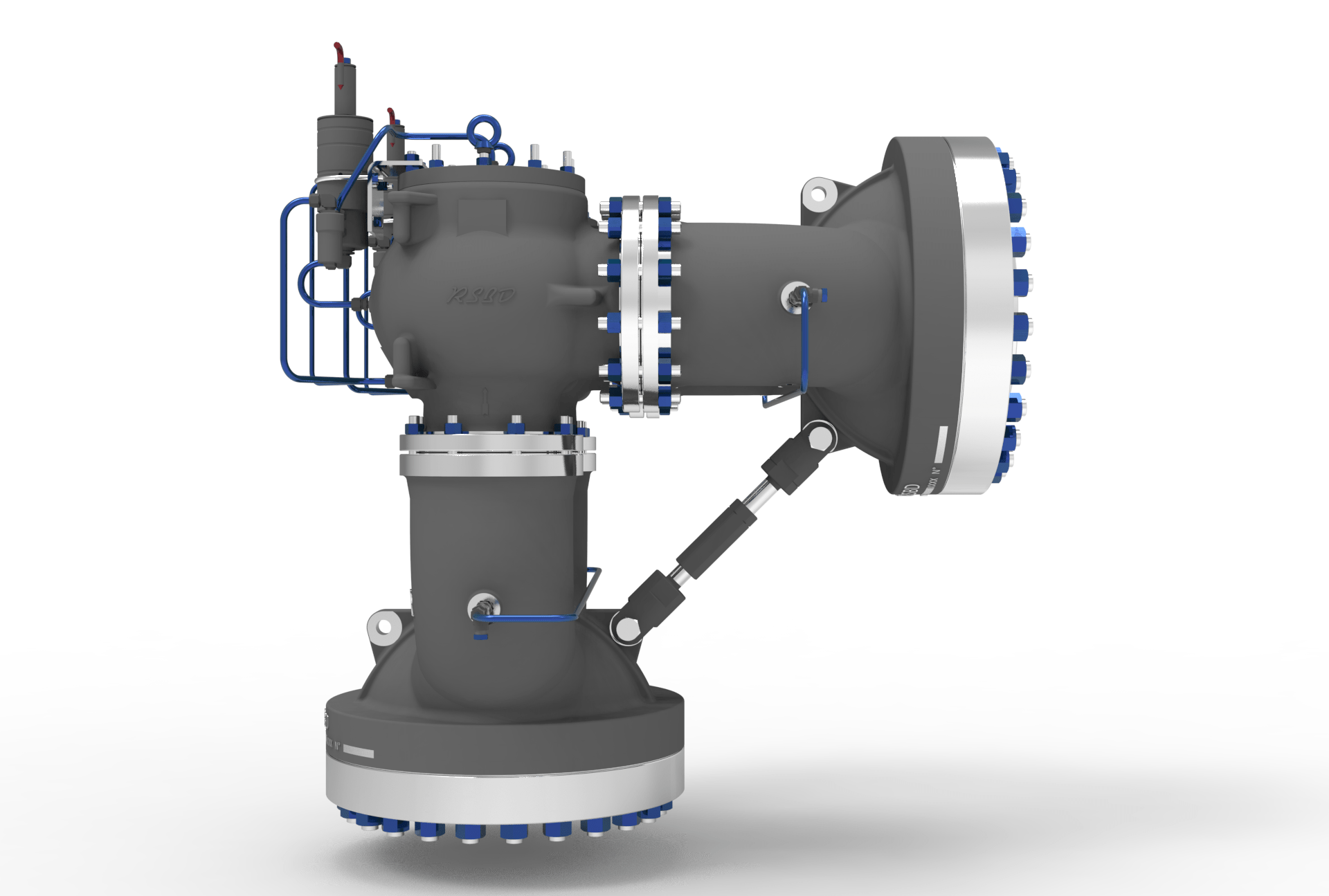

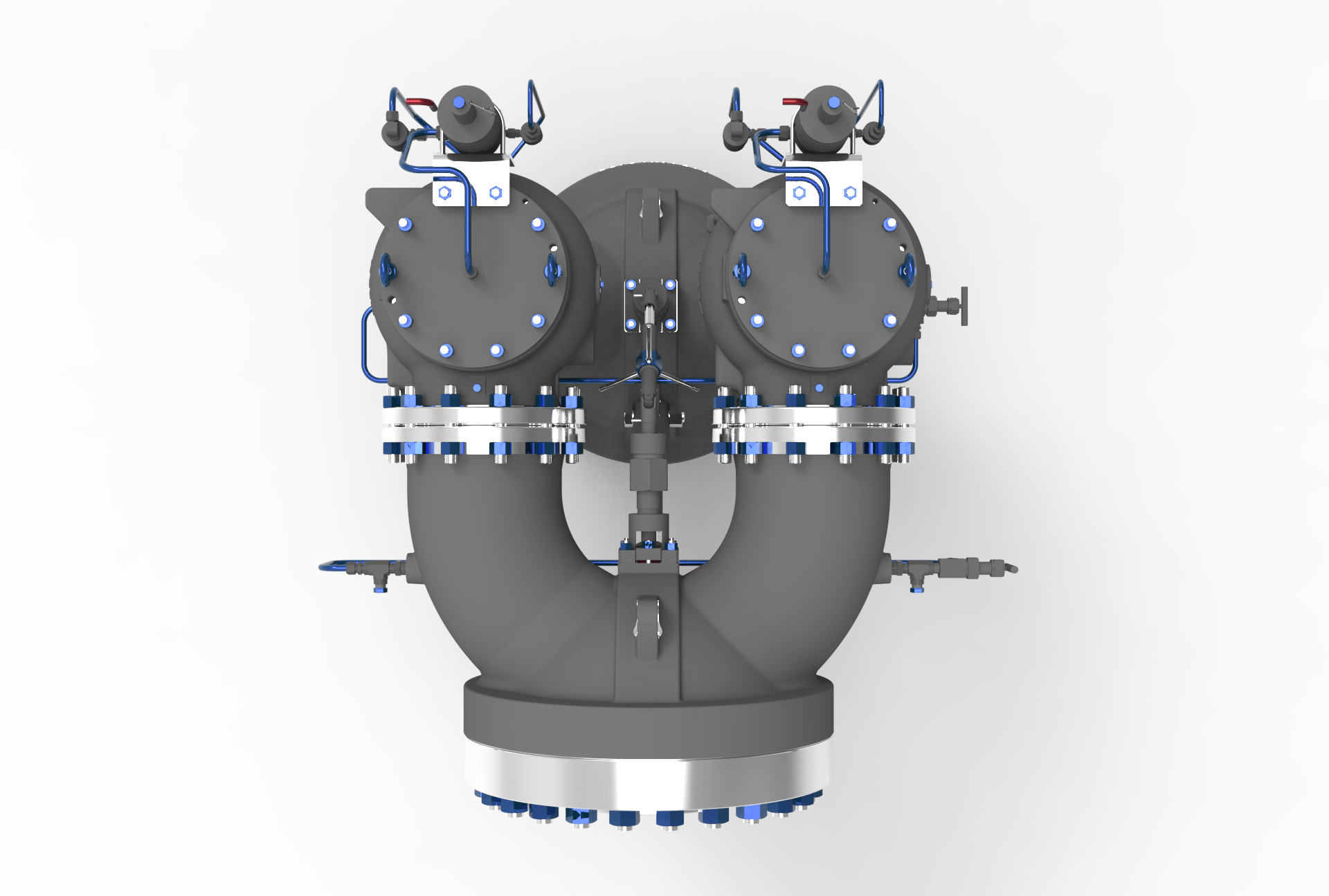

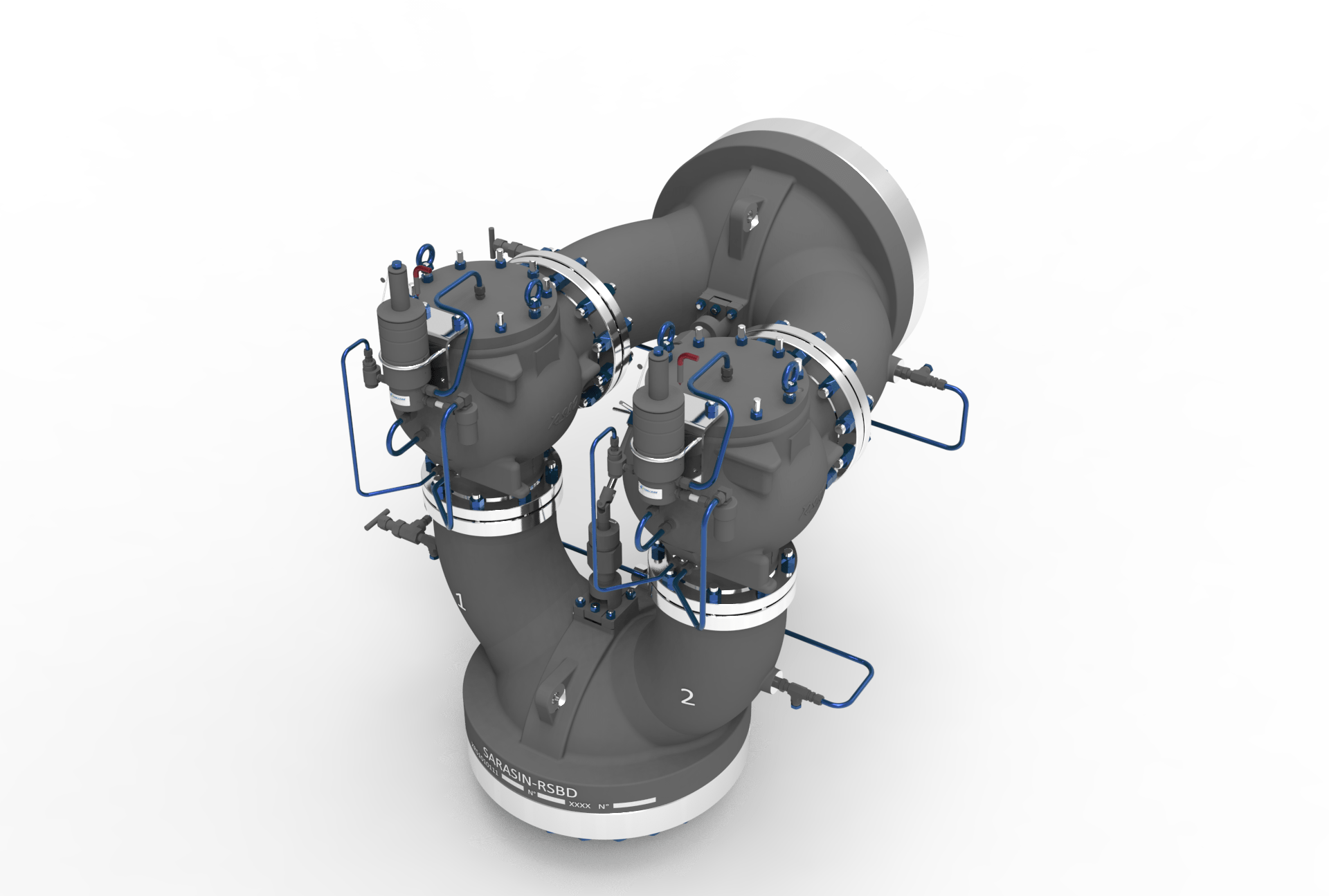

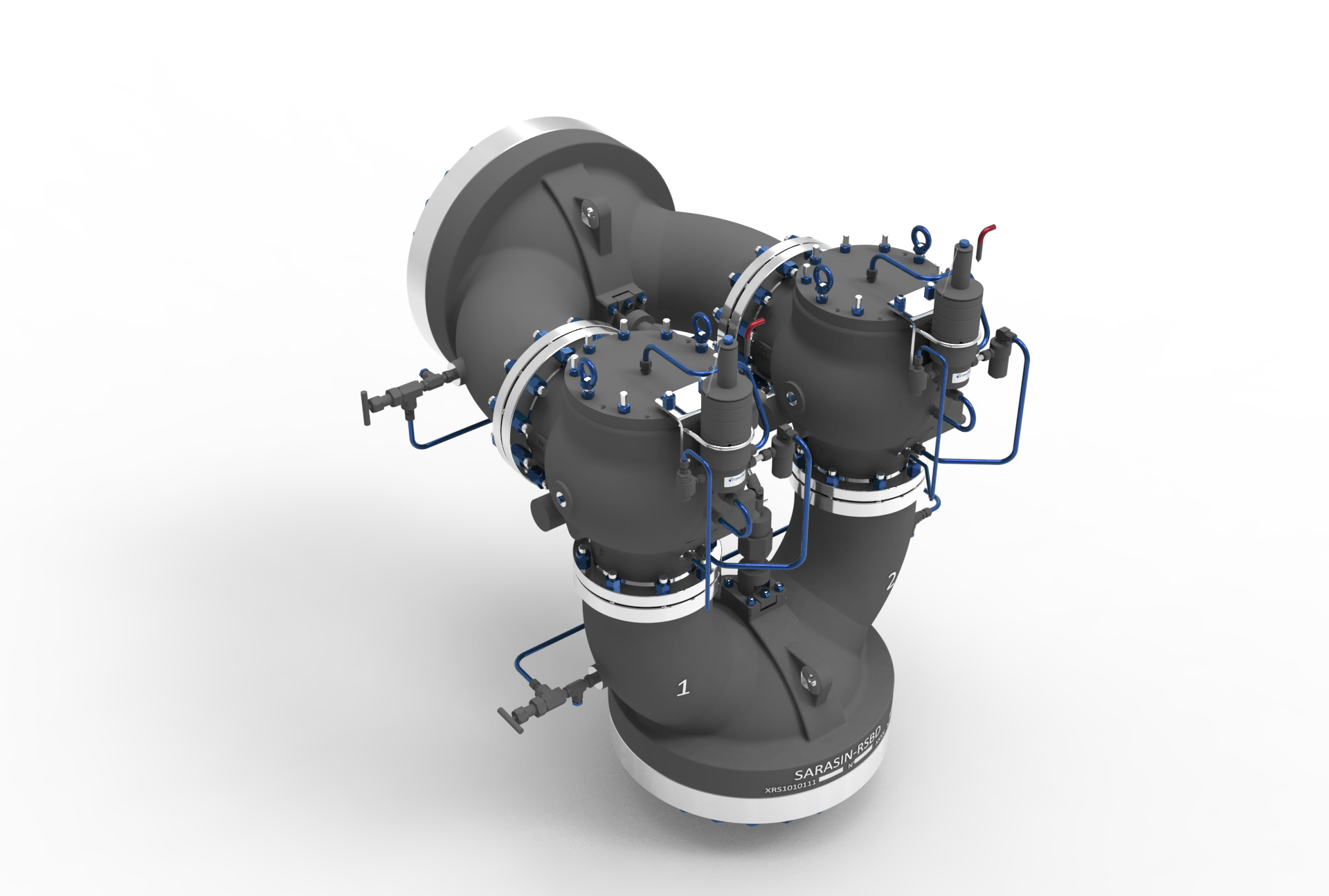

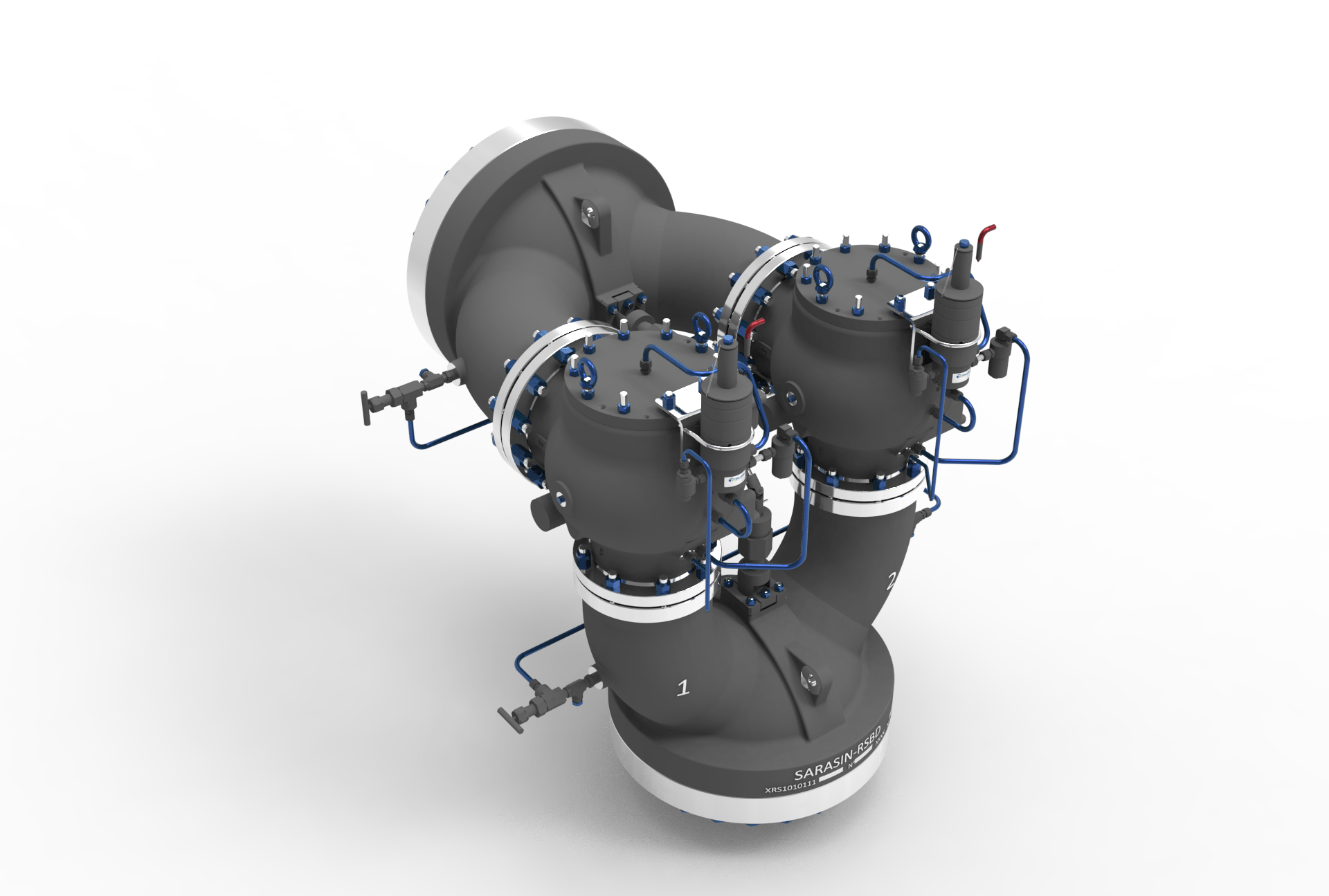

Sarasin-RSBD®

Starvalve (RS type) Changeover Valve

Due to the changeover valve design, no seat lapping is required for maintenance, meaning there are minimal spare parts and a reduced cost of ownership. It reduces the risk of a pressure relief valve chattering from excessive pressure drop through traditional shuttle type changeover valves. The Sarasin-RSBD® Starvalve is a rotor type changeover valve which maintains a pressure drop of pressure below 3% through its body. This changeover valve is designed for use in refineries within the petrochemical and cryogenic industries.

KEY FEATURES & BENEFITS

-

Rotor type maintaining a pressure drop of pressure below 3% through its body

-

Clear, positive indication of the active pressure relief valve

-

Tested packing design plus minimal leak points ensure reduced fugitive emissions

-

No seat lapping is required for maintenance

-

Minimal spare parts reduce the cost of ownership

-

Simple operation, built-in seat equalization, and no special tool requirements minimize the total valve operating time

-

Tandem design (single way) for dual pressure relief valves which are discharging into a closed header system

APPLICATIONS

-

Refineries Petrochemical and Chemical installations

DESIGN STANDARDS

-

ASME B16.34, PED 2014/68/UE

DESIGN RATINGS

-

ASME Class 150 to 600

SIZE RANGE & DIMENSIONS

-

Single way: 50mm (2 inches), 2 x 50mm (2 inches) to 250mm (10 inches), 2 x 250mm (10 inches)

-

Double way: 50mm (2 inches) - 2 x 25mm (1 inch) to 250mm (10 inches) - 2 x 200mm (8 inches)

TEMPERATURE RANGE

-

-60ºC - 427ºC (-76°F - 800°F)

CAPACITY

-

Individually calculated and selected for each process application

MATERIALS

-

Carbon steel, various carbon & chrome moly steels austenitic stainless steels