Loading 3D model...

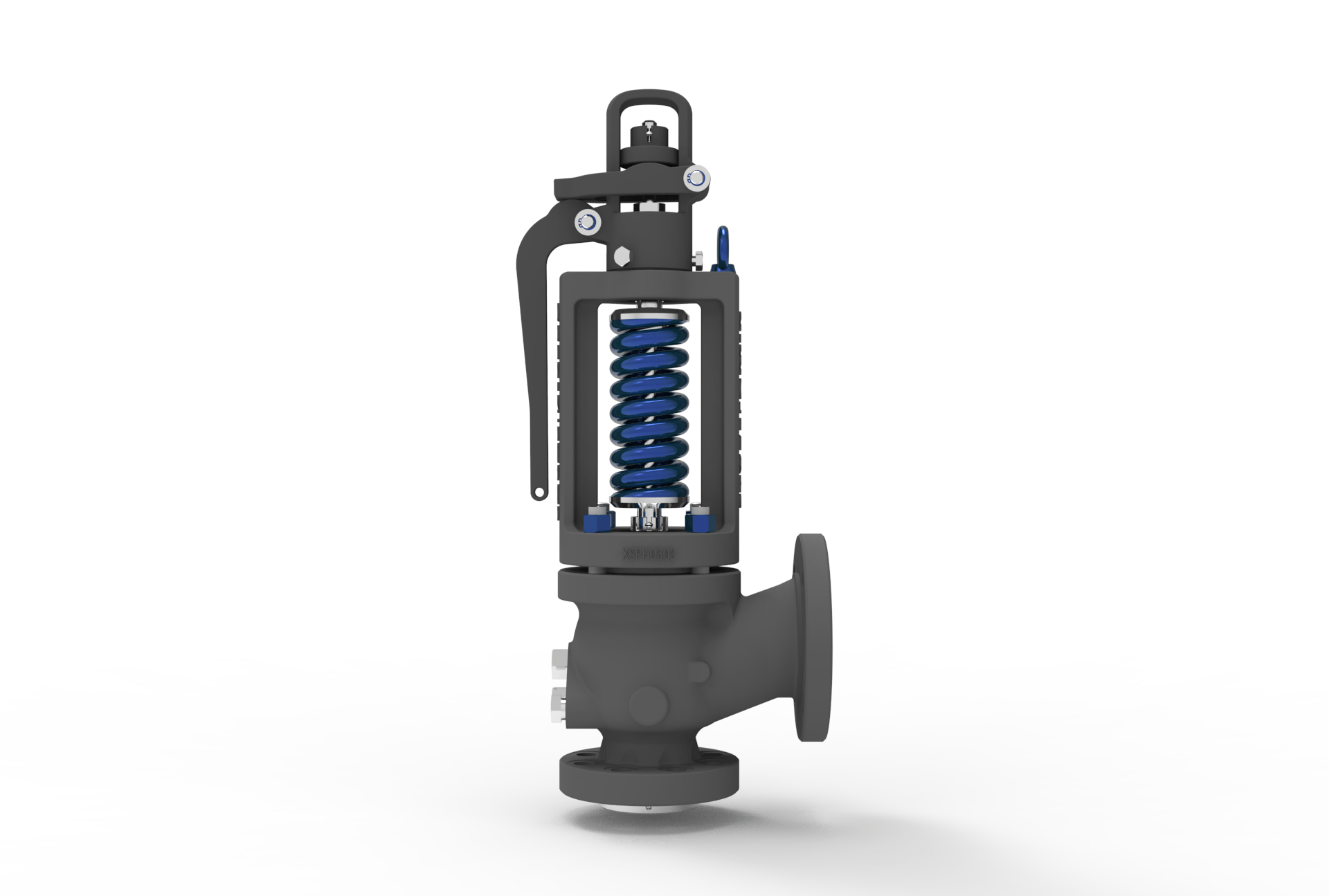

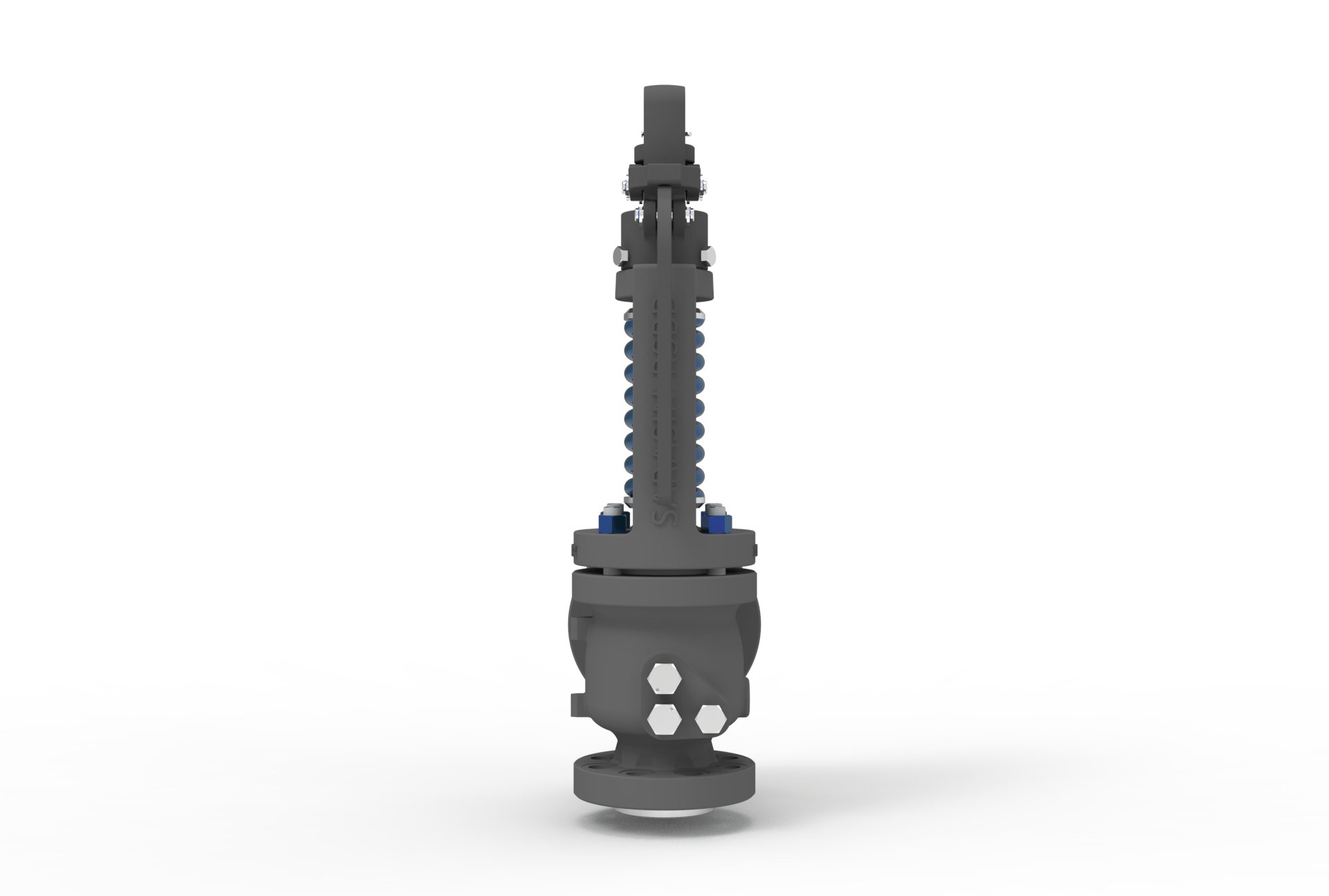

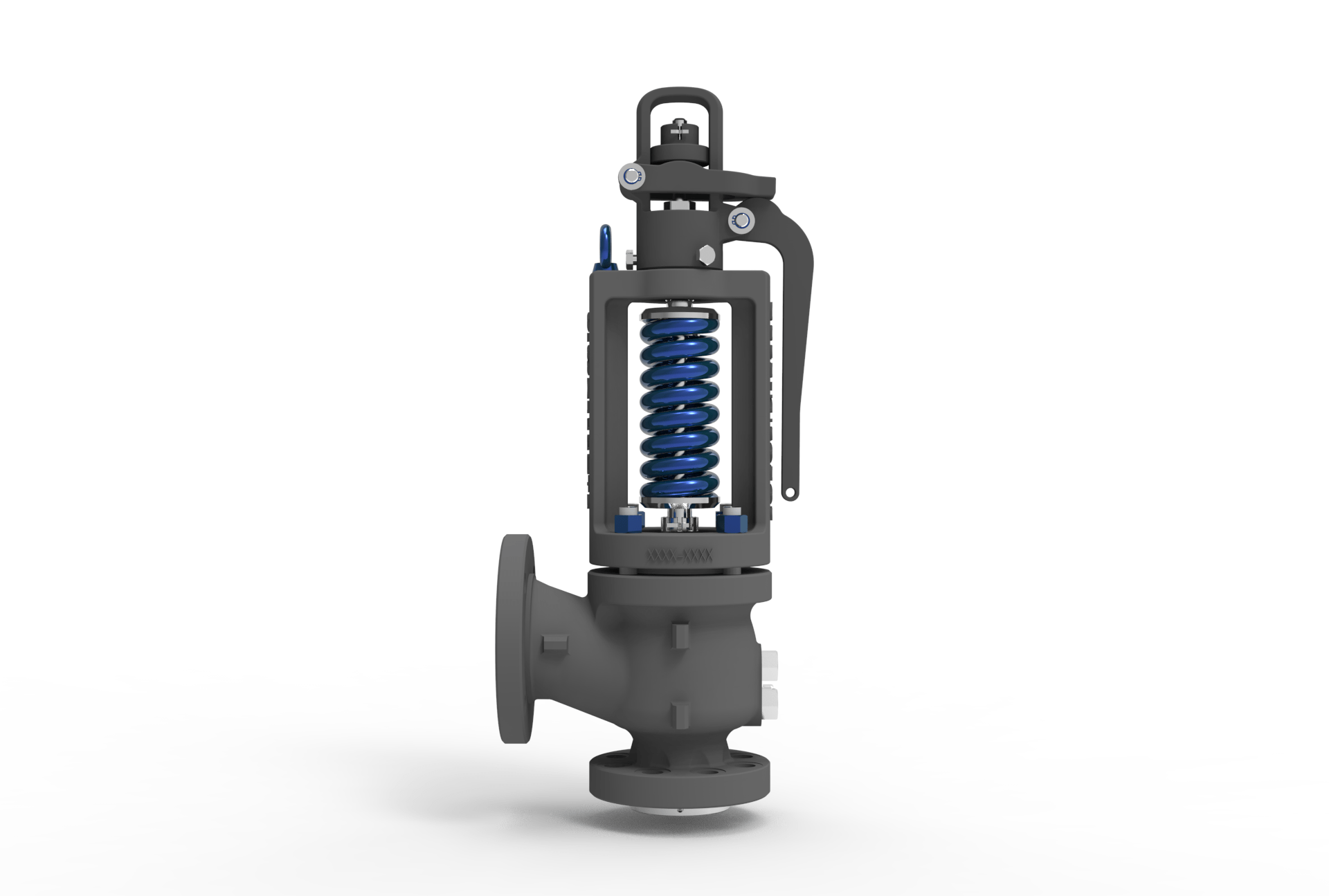

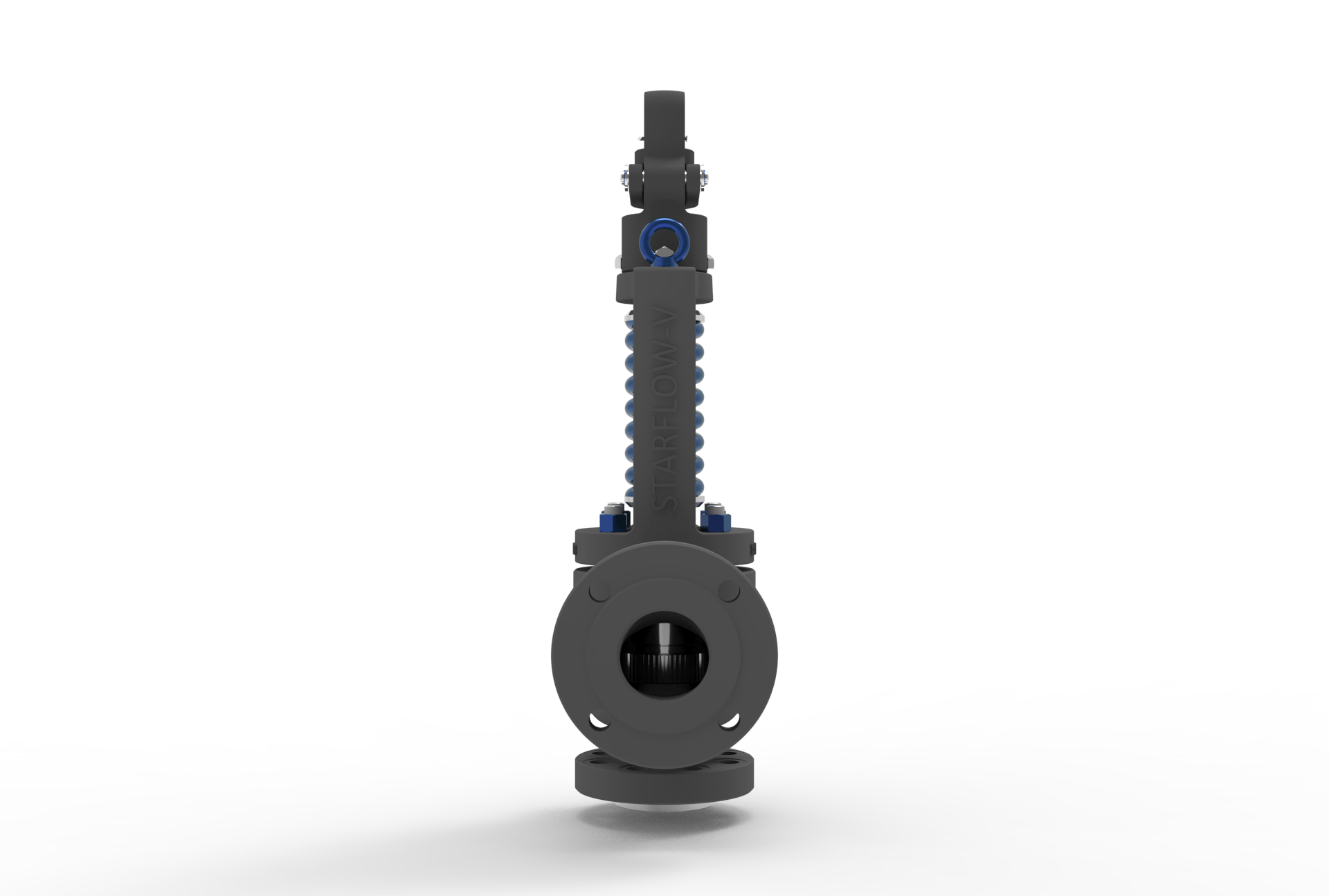

Sarasin-RSBD®

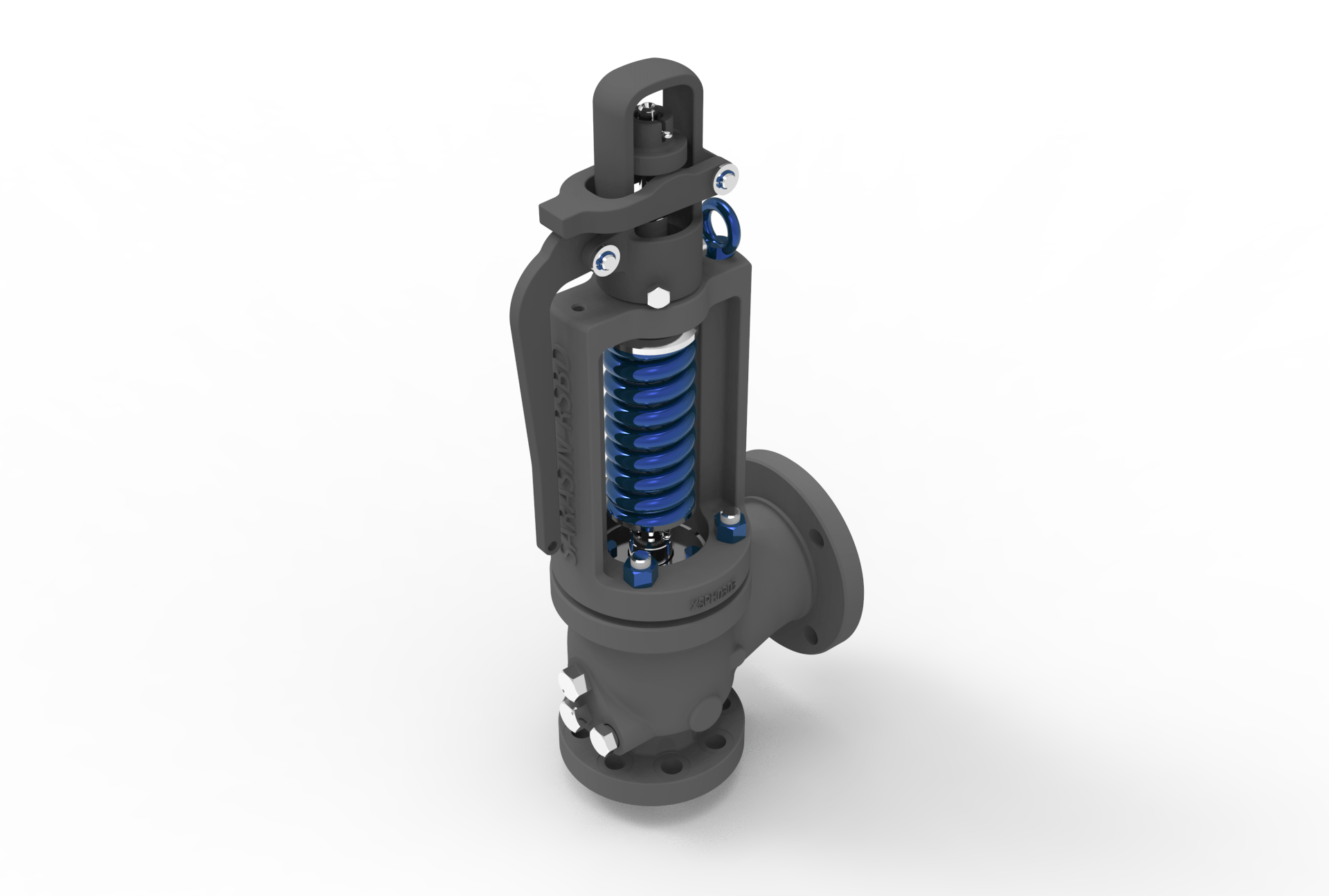

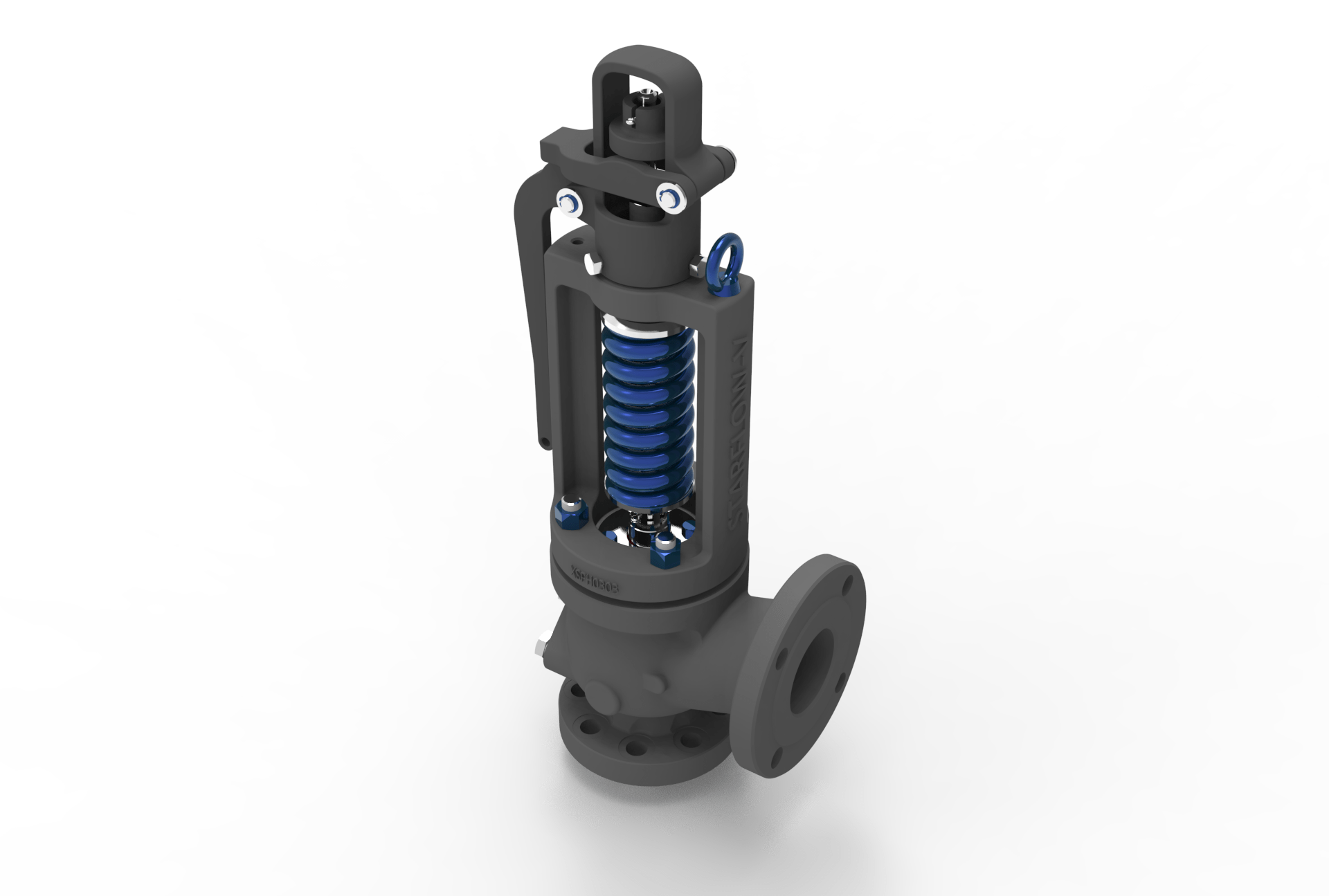

Starflow-V (PV Series) Pressure Relief Valve

The Starflow V Pressure Relief Valve compliments the existing Starflow P and Starsteam offerings.

The additional option allows boiler manufacturers and plant operators to deal with a single supplier for multiple sizes and pressure conditions ranging from 1 to 8 inches (1 bar (14 psig) to 370 bar (5,366 psig)).

The Starflow Pressure Relief Valve range has been designed to work in a number of processes including multipurpose flow control and pressure relief within the power industry. Furthermore, with the addition of the Starflow V, Trillium Flow Technologies™ now offers its customers a fully inclusive product range available for boiler applications up to supercritical operational levels.

KEY FEATURES & BENEFITS

-

Composite design

-

ASME B&PV Code Section I and VIII certified valves (full lift and restricted lift)

-

Anti-seizing capability to prevent galling or sticking of internal components in the event of inconsistent operation or chattering

-

Spring loaded safety valves with fully metallic seat surfaces

-

Exposed spring for effective venting of steam

-

High performance

-

Effective flow coefficient granted by National Board (USA) in accordance with the ASME B&PV Code

-

High pressure ratings to attain maximum set pressures

-

Specially designed and contoured disc to optimize steam flow & seat tightness

-

Effectively designed body chamber to optimize blowdown reaction time

-

Anti-seizing capability to ensure accurate & repeatable opening pressures

-

Control of the cost of product ownership

-

Availability of large orifice sizes can minimize the quantity of selected valves and thus reduce the cost of acquisition and maintenance

-

Anti-seizing capability will assist to control the cost of operation, maintenance, and spare parts

DESIGN STANDARDS

-

ASME BPVC section I & VIII

SIZE RANGE & DIMENSIONS

-

Inlet sizes: 1.5 - 12 inches

PRESSURE CLASS & POWER

-

ANSI Class 150 through 1500 FLANGED (B16.5)

TEMPERATURE RANGE

-

Up to 649ºC (1200°F)

CAPACITY

-

Calculated and selected for each process application

MATERIALS

-

SA 216 Gr. WCCSA 217 Gr. WC6/WC9SA 351 Gr. CF8M

-

SA216 Gr. WCC

-

SA217 Gr. WC6/WC9/C12A

-

SA351 G. CF8M