Loading 3D model...

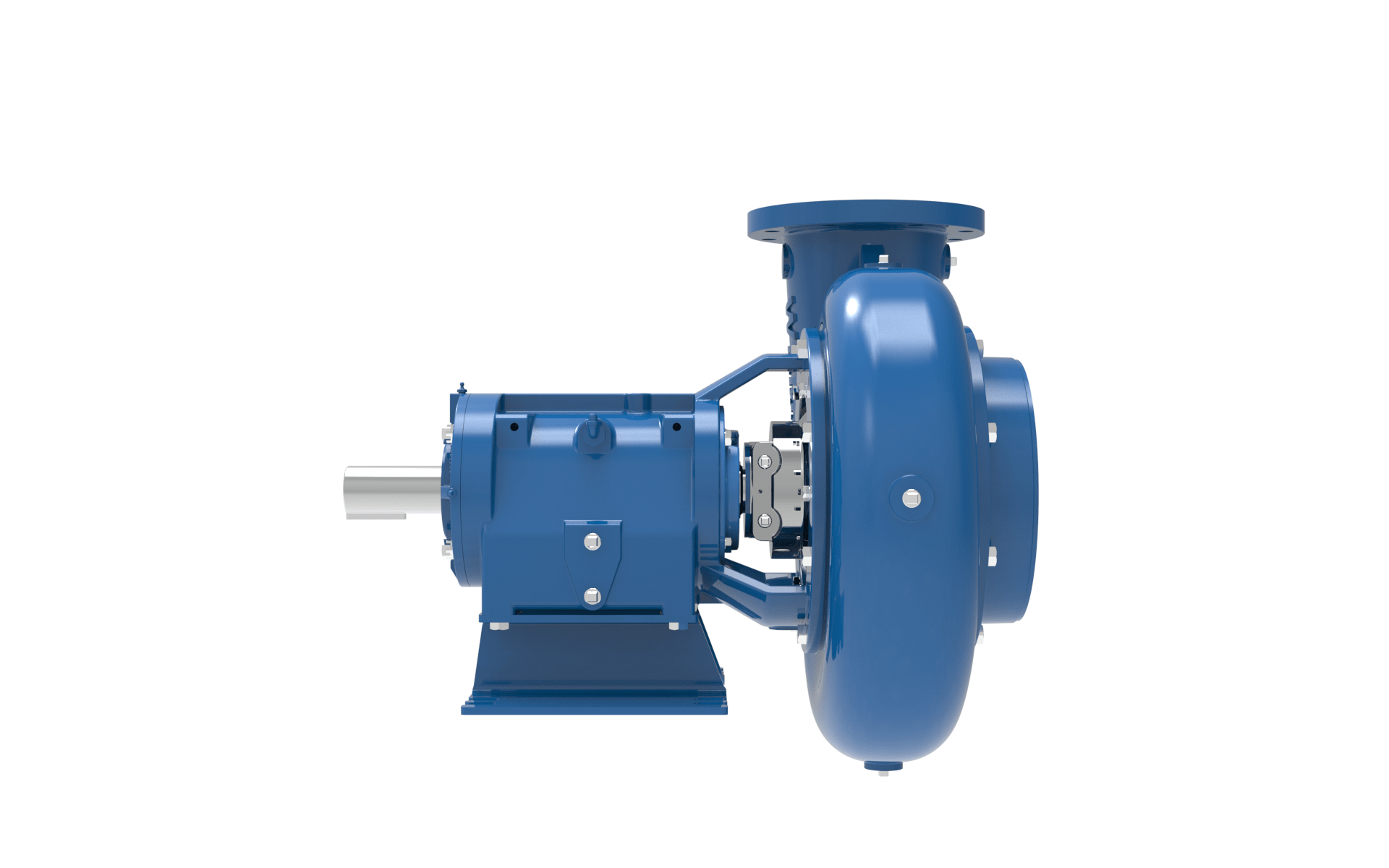

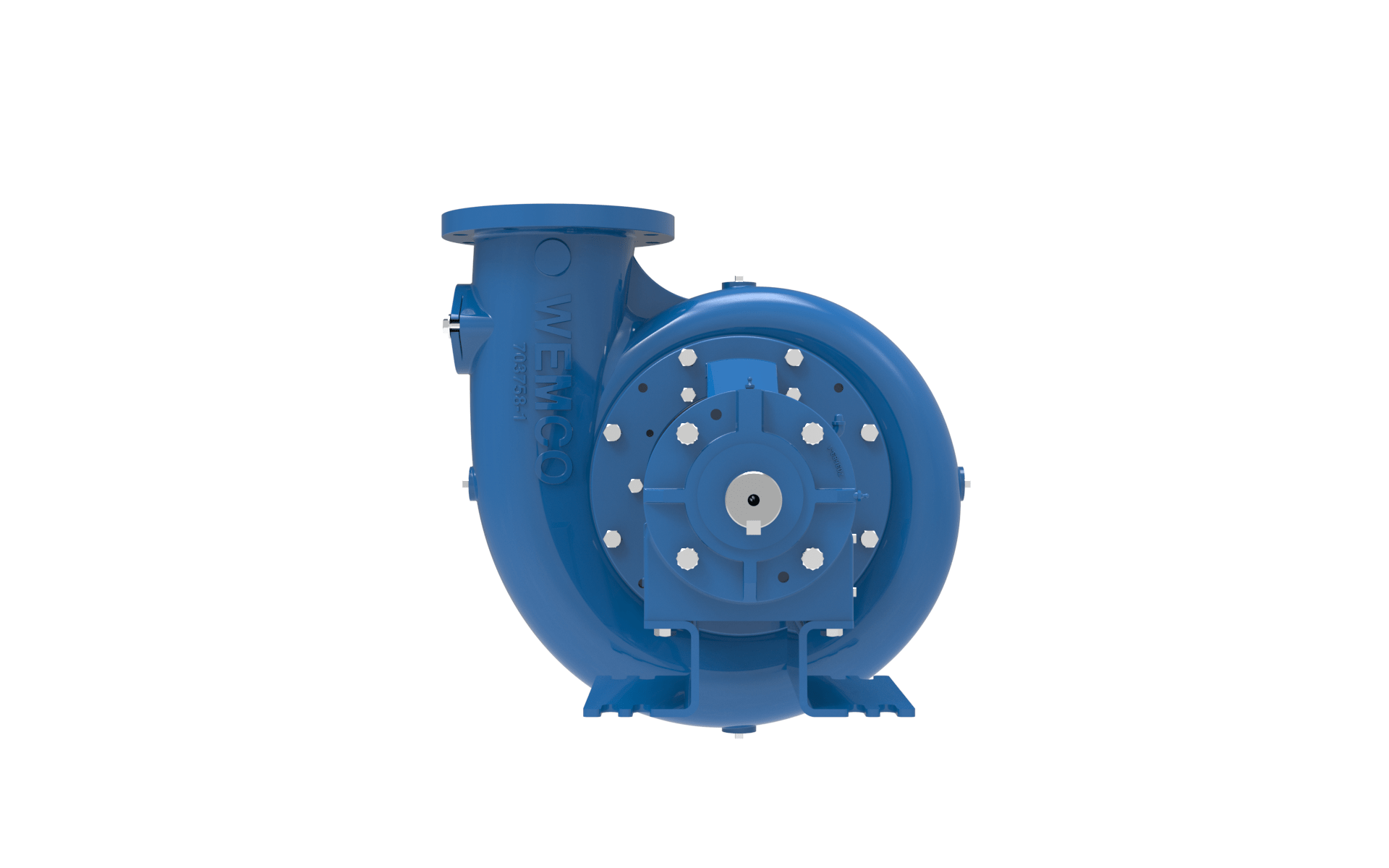

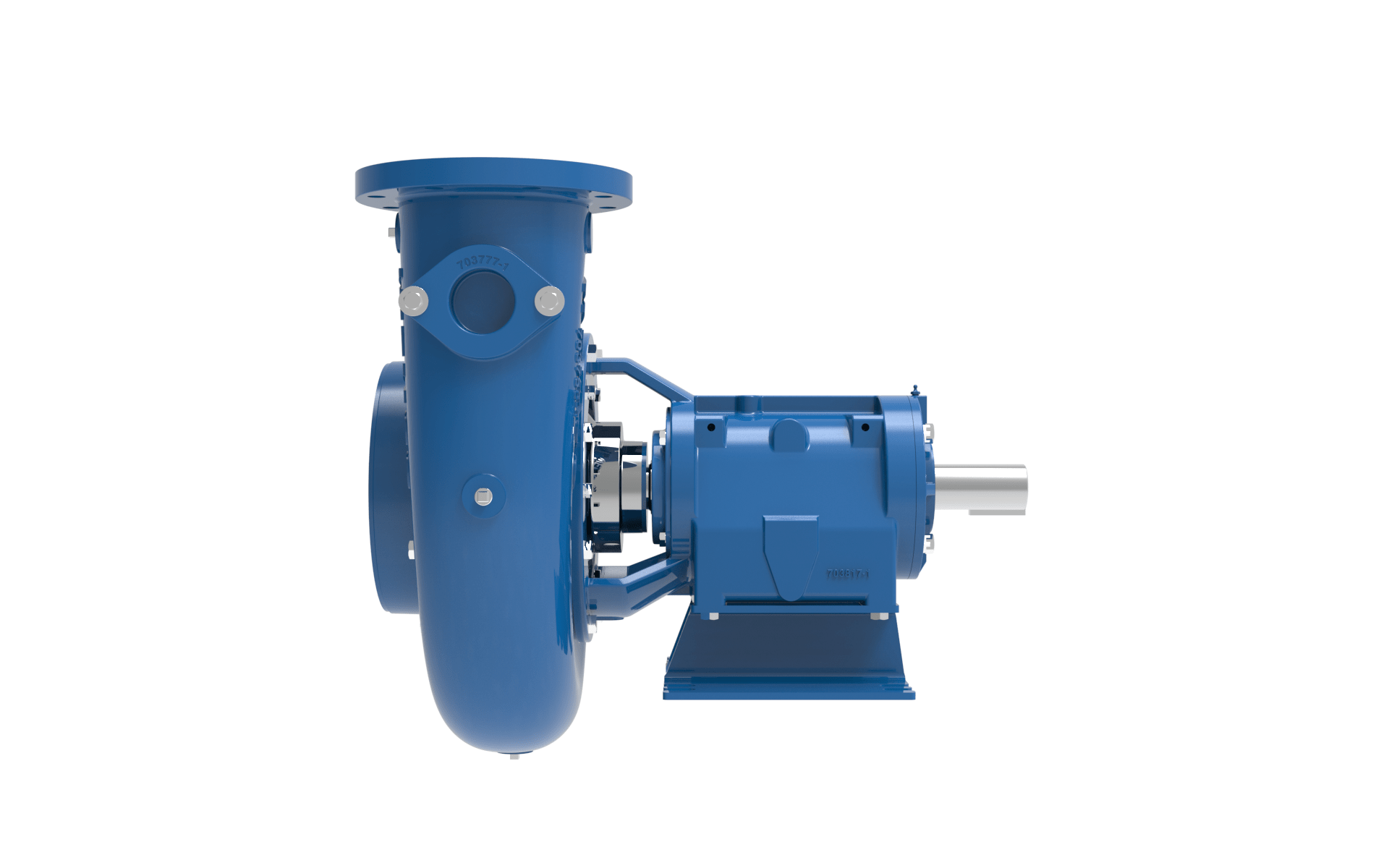

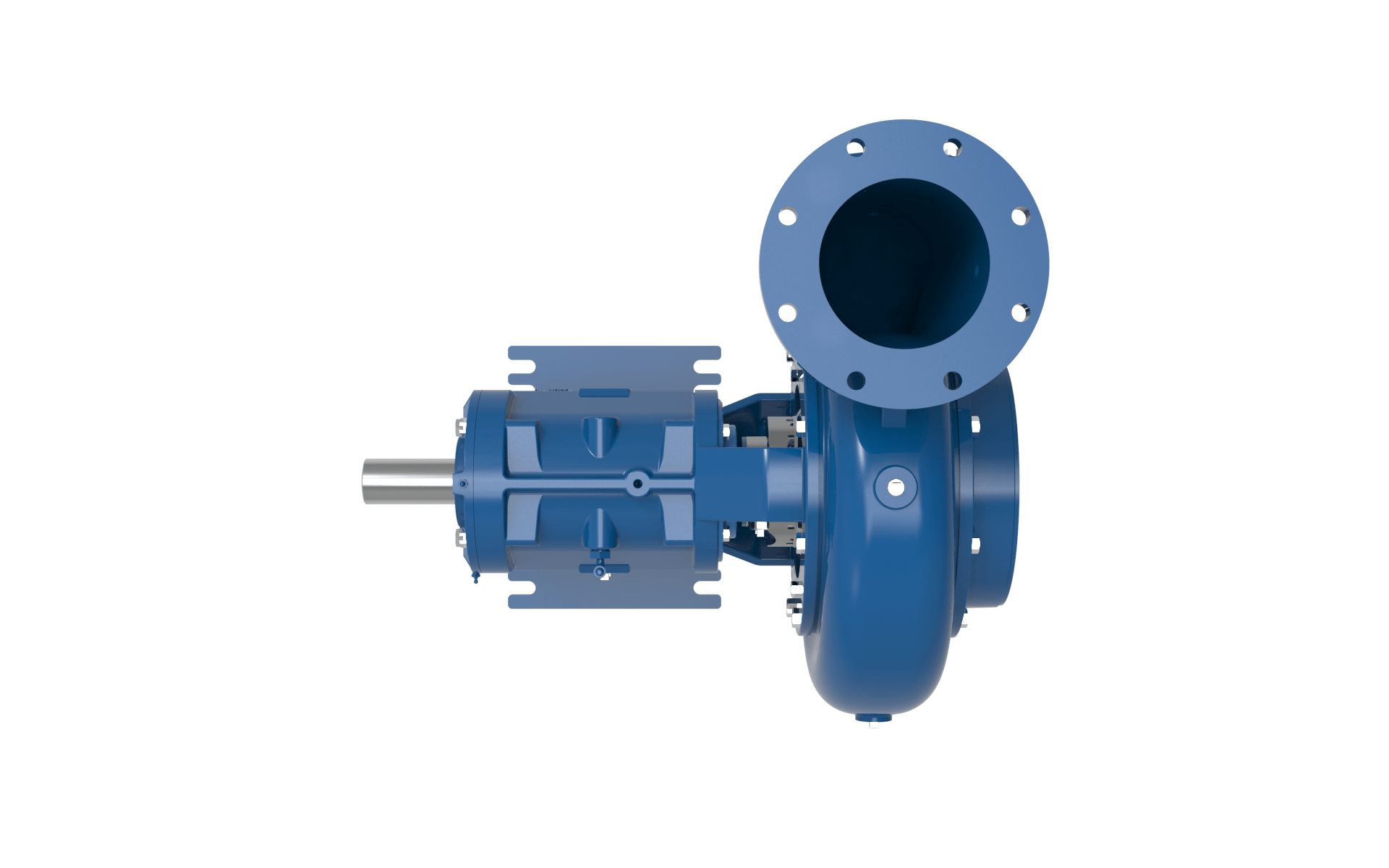

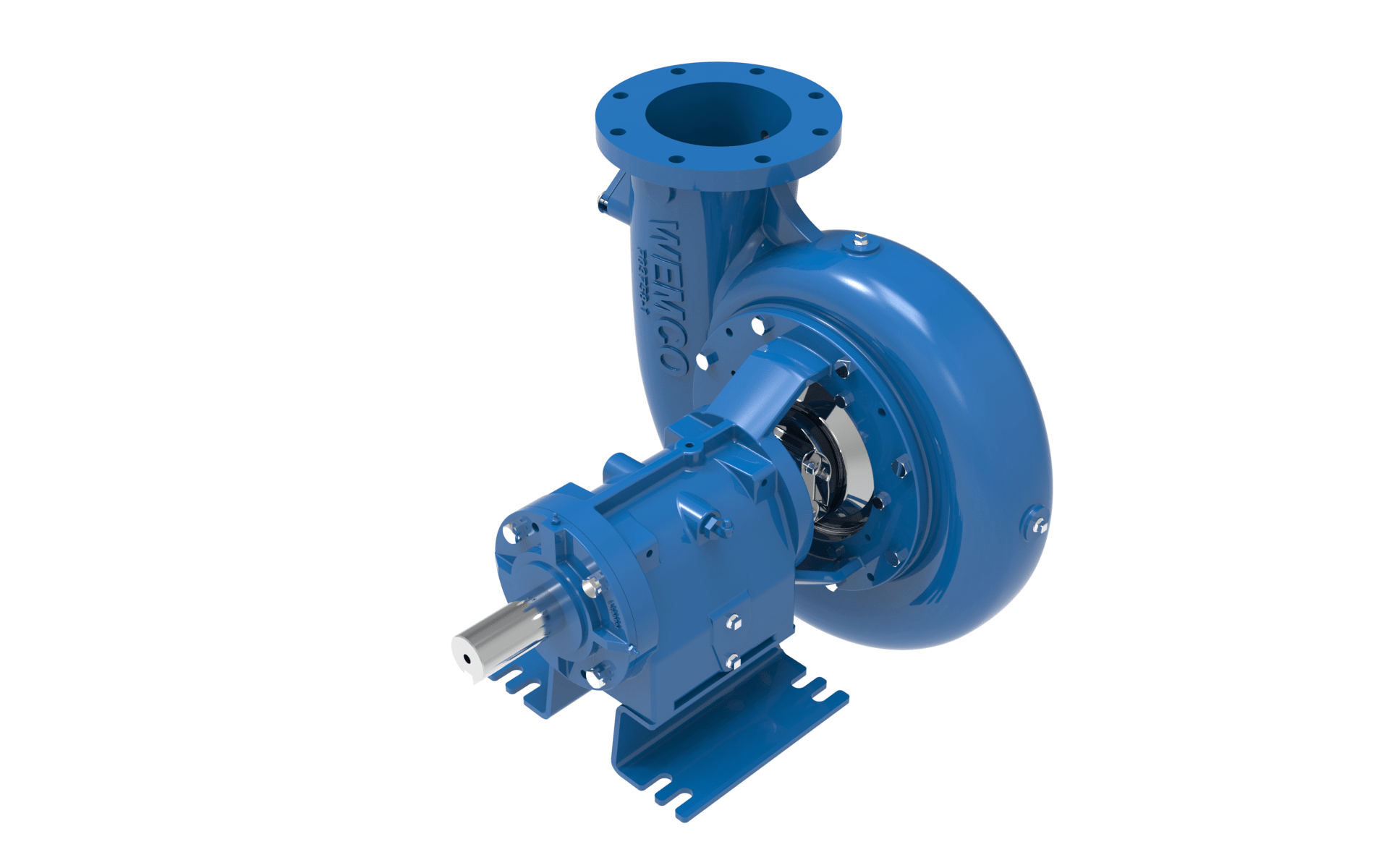

WSP™

Non-Clog

The WSP™ Non-Clog is a heavy-duty pump perfectly designed to maintain high hydraulic efficiencies while handling large solids.

The WSP™ Non-Clog pumps were designed and developed using advanced technology to meet demanding market requirements.

The Non-Clog design is a vastly improved, modernized design compared to conventional non-clog pumps in the marketplace.

It benefits from the latest 3D computer aided design technology, which improves overall pump efficiencies and reduces maintenance and operating costs. The WSP™ Non-Clog is available in four sizes ranging from 4 inch (100mm) to 12 inch (300mm) with the true ability to pass a 3 inch (75mm) solid.

The WSP™ Non-Clog pumps were designed and developed using advanced technology to meet demanding market requirements.

The Non-Clog design is a vastly improved, modernized design compared to conventional non-clog pumps in the marketplace.

It benefits from the latest 3D computer aided design technology, which improves overall pump efficiencies and reduces maintenance and operating costs. The WSP™ Non-Clog is available in four sizes ranging from 4 inch (100mm) to 12 inch (300mm) with the true ability to pass a 3 inch (75mm) solid.

KEY FEATURES & BENEFITS

-

Engine-driven (trailer or skid mounted)

-

Extended operational life

-

Large clean-out port

-

Combined bearing frame and bracket to increase rigidity and reliability

-

Prime Assist option available

APPLICATIONS

-

Sewage Lift Stations

-

Return Activated Sludge

-

Waste Activated Sludge

-

Sewage Bypass

-

Dewatering

-

Digesters

-

Water Booster

-

Manure

-

Industrial Waste

-

Light Abrasives

-

Agricultural Waste

-

Mining

-

Fracking

SIZE RANGE & DIMENSIONS

-

4, 6, 8, & 12 inch

TEMPERATURE RANGE

-

41ºF (5°C) - 250ºF (121°C)

CAPACITY FLOW

-

Up to 10,000 gpm (2,498 m³/h)

HEAD

-

Up to 300 ft. (91 m)

MATERIALS CASE

-

Cast iron

-

CD4

-

Skotchkoting of the volute

IMPELLER

-

Cast iron, hi-chrome

-

CD4