Loading 3D model...

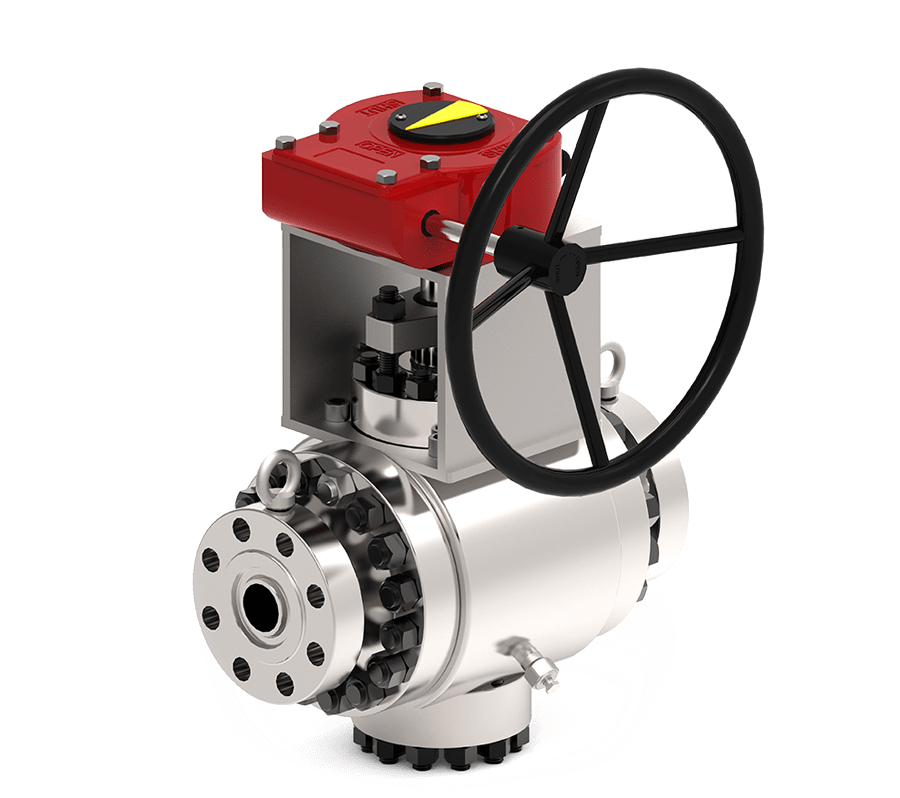

Red Point®

Metal seated TRM Ball valves

Red Point’s metal seated TRM ball valves can be deployed for a wide variety of applications in the oil & gas, petrochemical, mining, and power industries when high quality, reliable valves are required.

Construction

-

Two Piece Body or Three Piece Body

-

Blow-Out Proof Stem

End connections

-

Flanged

-

BW

-

SW

-

THR

-

HUB

Design

-

API6D

-

ASME B16.34

Face to Face

-

ASME B16.10

-

EN558

-

JIS B2002

-

MSS SP72

Fugitive emission

-

ISO EN15848-1

-

ISO EN15848-2

Options

-

Extended Bonnet

-

Lipseals

-

Local CRA Overlay

-

Injection Sealing Seat & Packing

-

Heating Jacket

-

Drain & Vent

-

AED Seals

-

DBB- DIB1 - DIB2 as per API6D

Pressure range

-

ANSI 150 - 4,500 lbs.

-

DIN PN 10 - PN 400

-

API 5,000 - 10,000 psi

Sealing

-

Uni-Directional or Bi-Directional

Operated

-

Lever, Gear, Actuator (pneumatic - electric - hydraulic)

Testing

-

API6D

-

API598

-

EN12266

-

MSS SP82

-

ISO5208

-

API6A

Fire Safe

-

Design and Certified API607, API6Fa, ISO10497

Mounting pad

-

ISO5211 - Top Flange

Size & bore

-

ANSI 1/4 - 16”

-

DN 6 - DN 400

Temperature

-

-196°C - 816°C (-320°F - 1,500°F)