Loading 3D model...

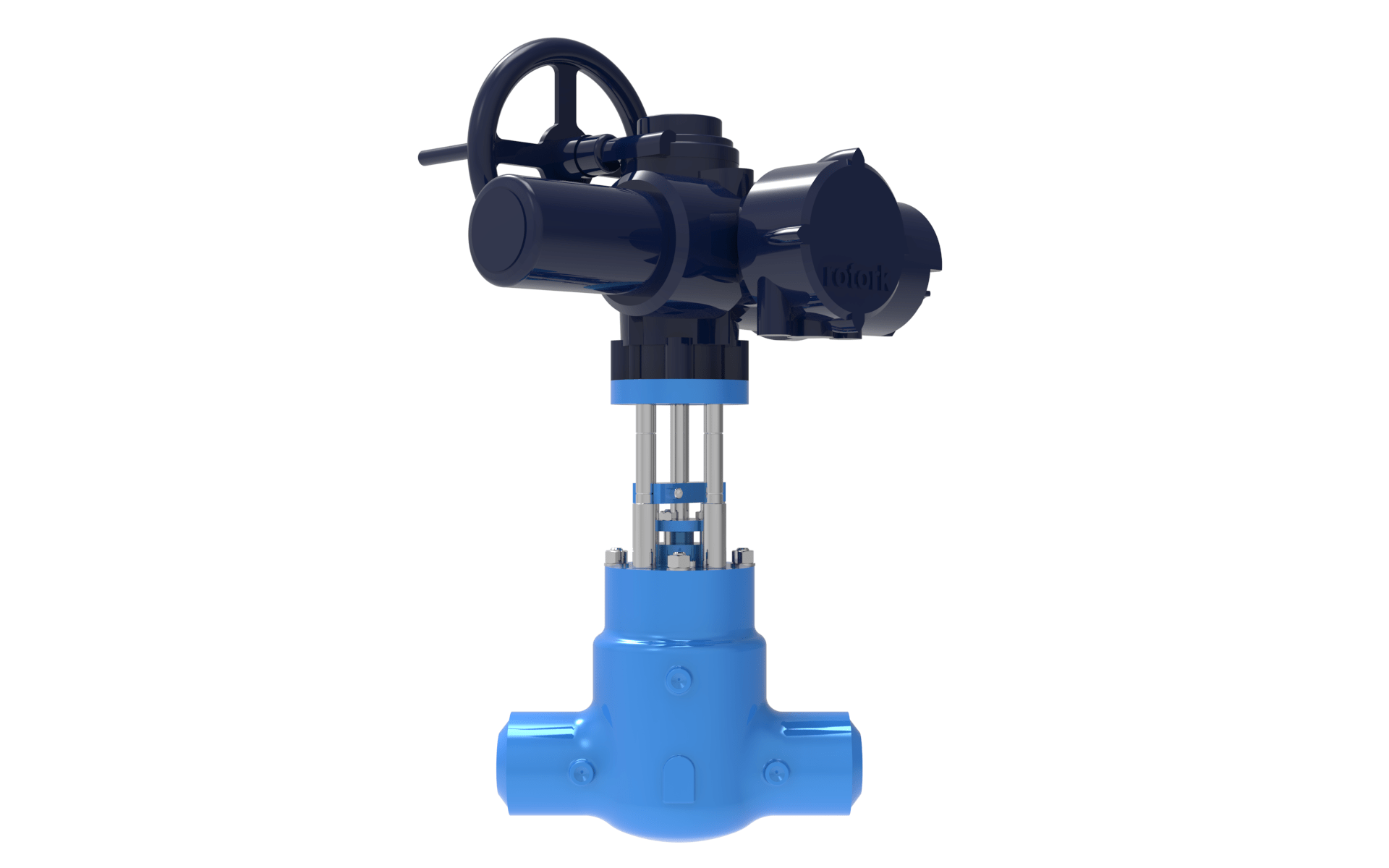

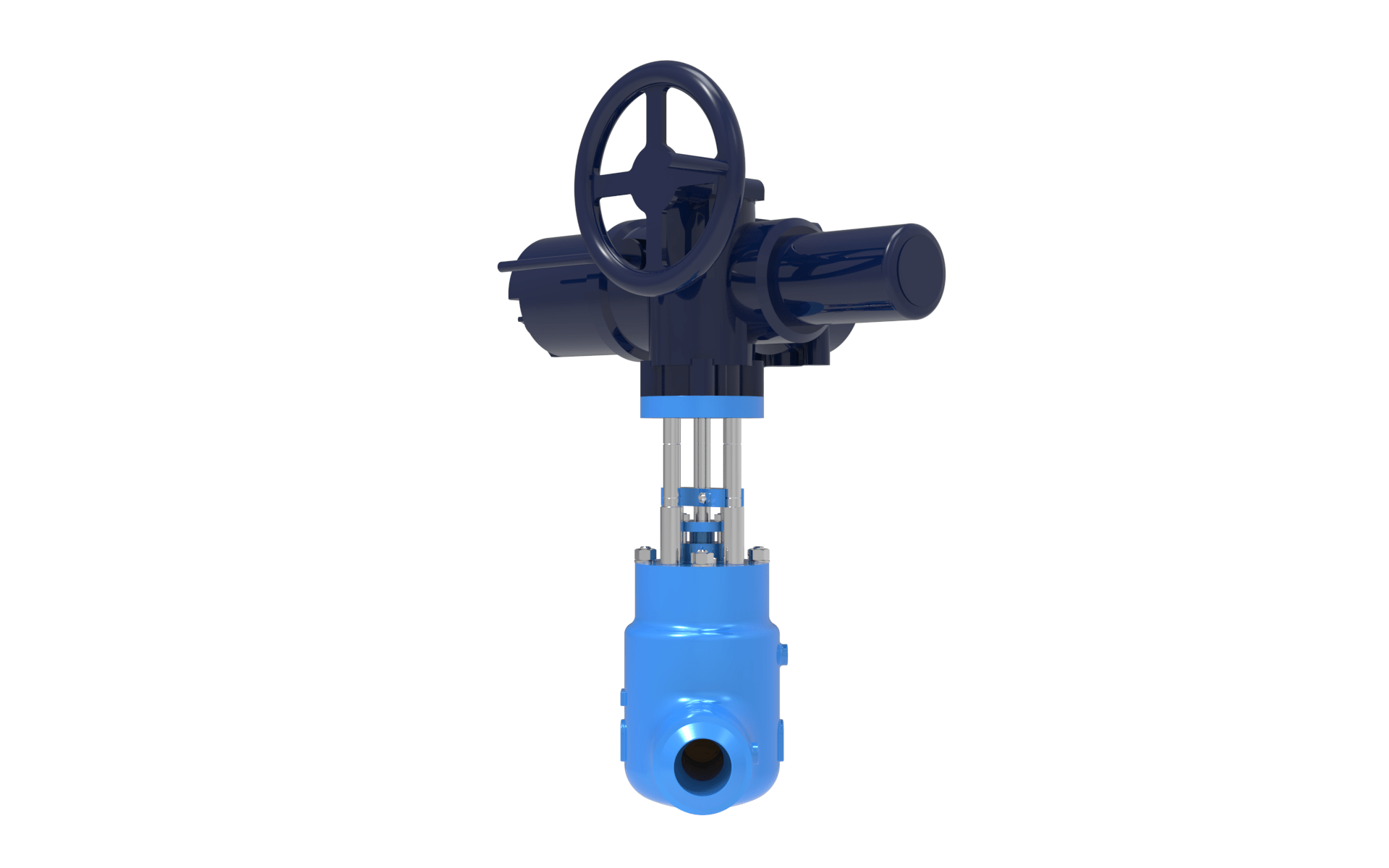

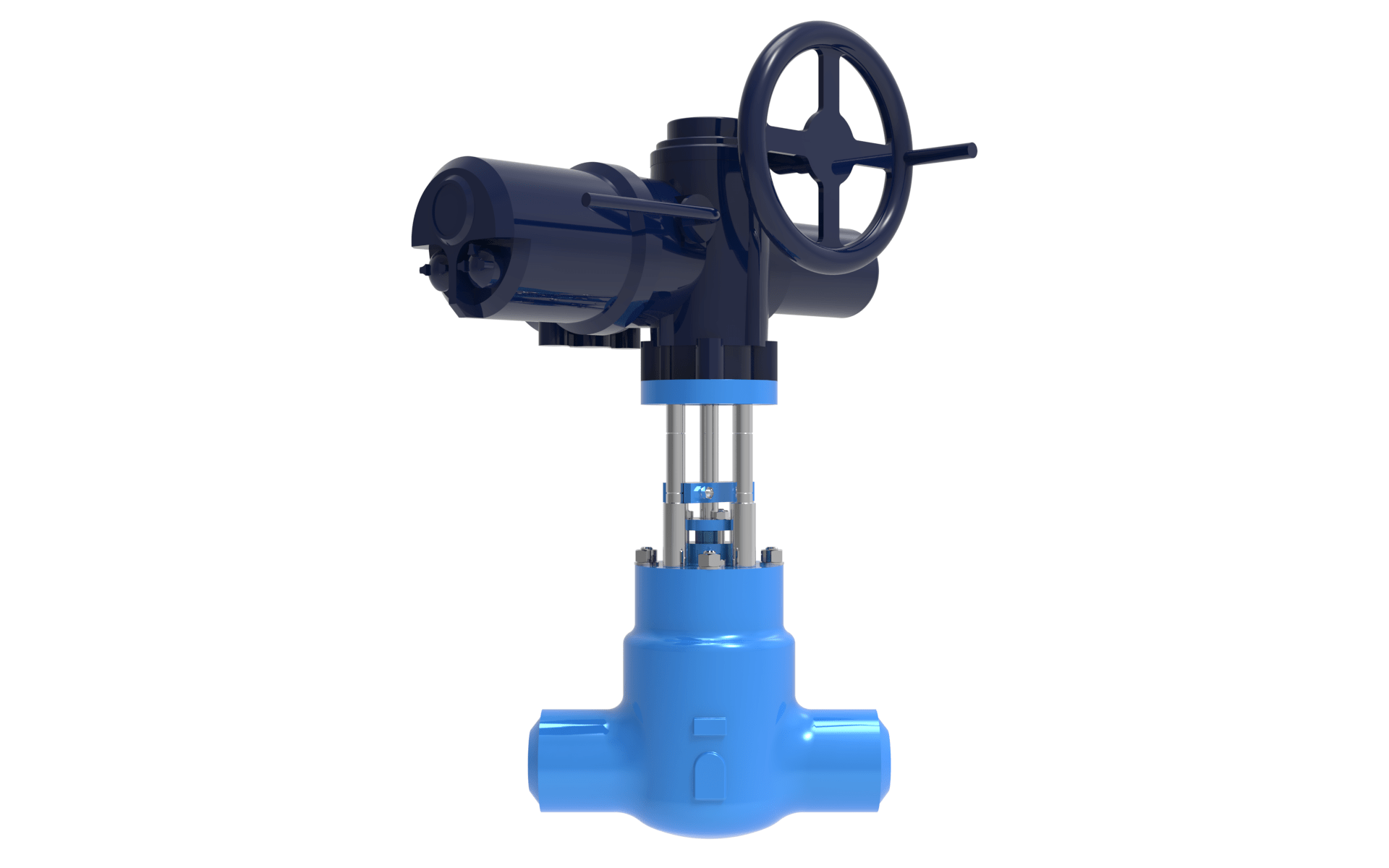

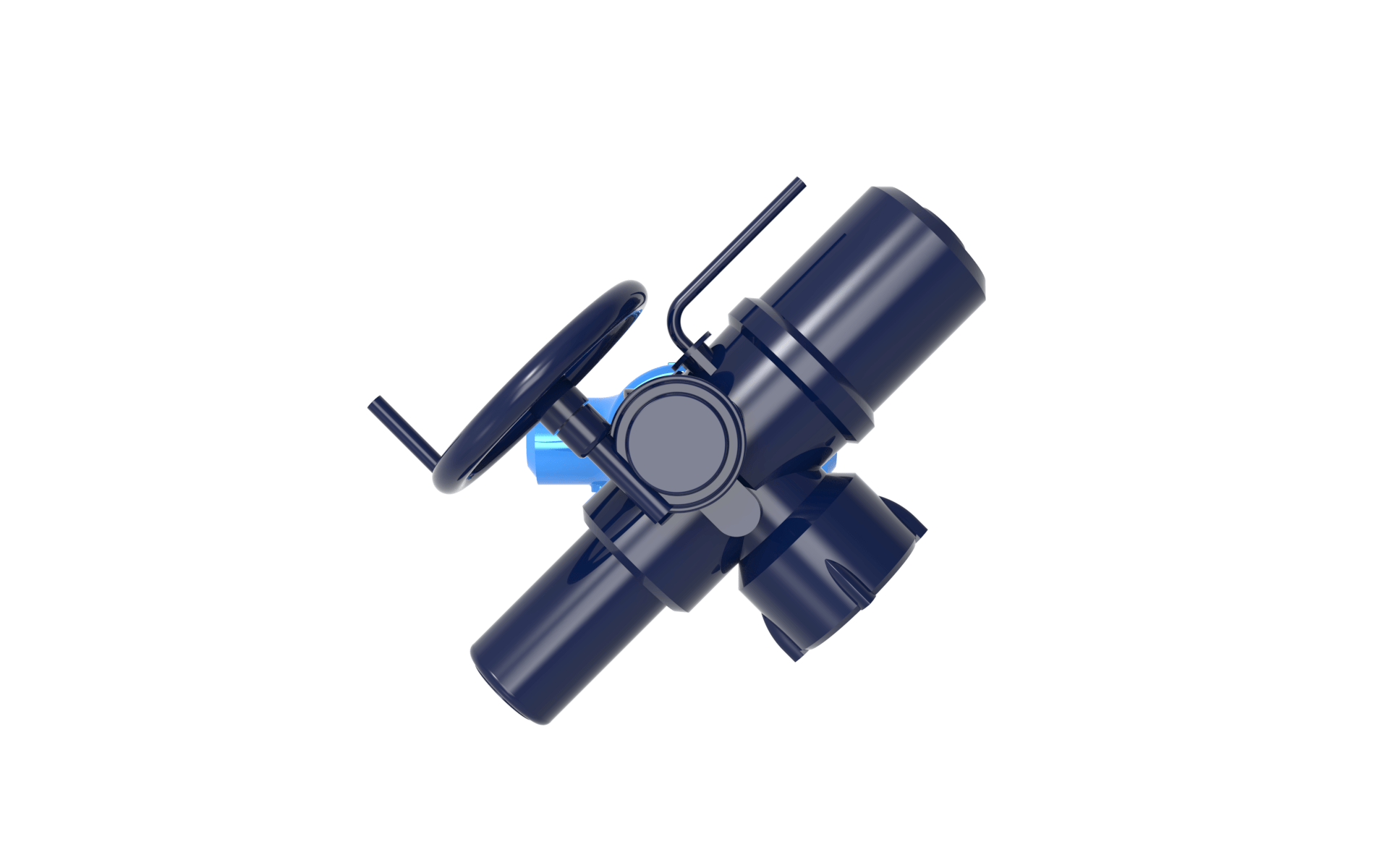

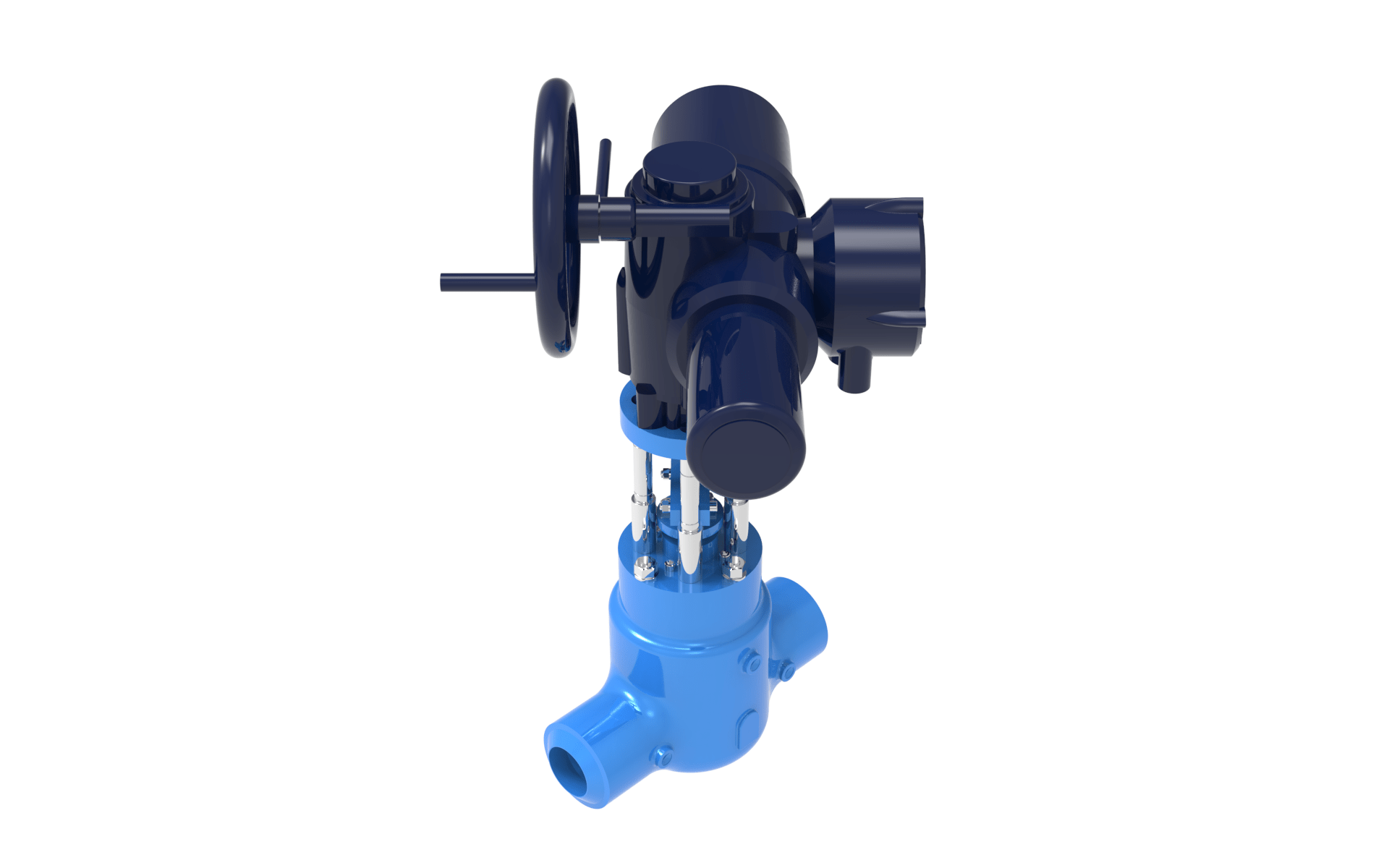

Hopkinsons®

High Performance Drain

Hopkinsons® High Performance Drains are designed to give extended service life and continued tight shut off when subject to frequent operation, two phase flow, thermal shock, and large pressure drops. Unique features of the valves include square discs (gates) and “winged” seats. These provide accurate gate guidance, low seat contact stresses, and enhanced wear resistance for repeatedly handling large pressure drops in the part open position.

KEY FEATURES & BENEFITS

-

The valves can be installed singly but for maximum effect, two valves operating in a martyr valve and master valve configuration are recommended. Winged seats – the seating area is extended in the open direction providing greater contact area with the gates.

-

Square gates – provide greater contact area and support during operation.

-

Titanium nitride coating gives improved erosion resistance.

-

Optional extras: Pipework – pairs of valves can be supplied with a joining piece of pipework welded and tested thereby simplifying site installation; Alternative “V” ports – the standard 50% “V” port provides excellent all round performance and is appropriate for the majority of applications. Where necessary, “V” ports from 20% to 80% area, and parallel ports from 5% to 30% area for linear regulation can be selected for specific applications.

MATERIALS

-

Carbon Steel

-

Alloy Steel

APPLICATIONS

-

Power plants condensate drainage

DESIGN STANDARDS

-

ASME B16.34

-

Alternatively, valves can be supplied to other national standards.

-

ASME section IIIRCC-M.

DESIGN RATINGS

-

ASME Class 900 to 3600

TEMPERATURE RANGE

-

29°C – 538°C (-20°F – 1000°F)

SIZE RANGE & DIMENSIONS

-

20 – 100 mm (0.75 – 4 inches)