Loading 3D model...

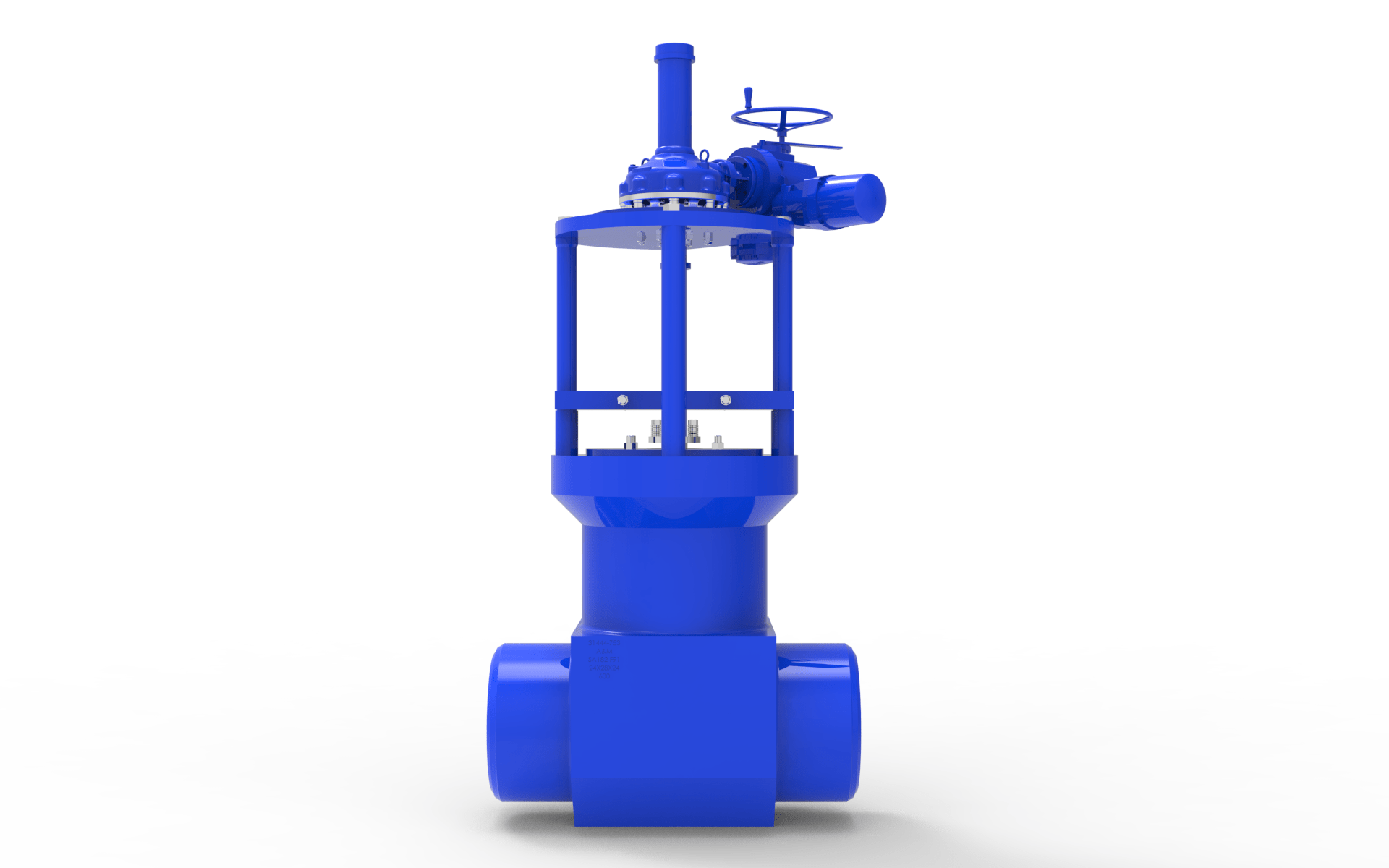

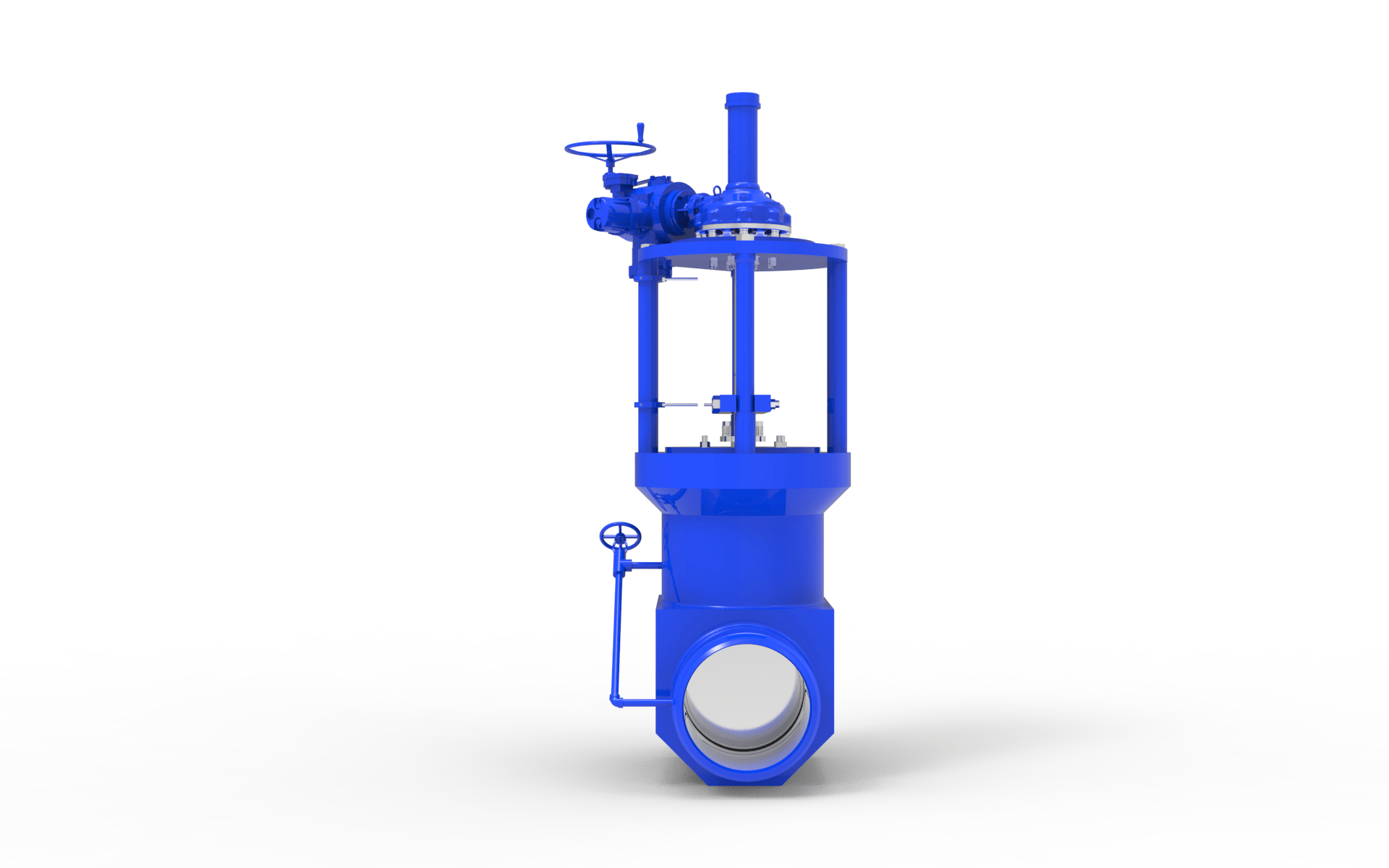

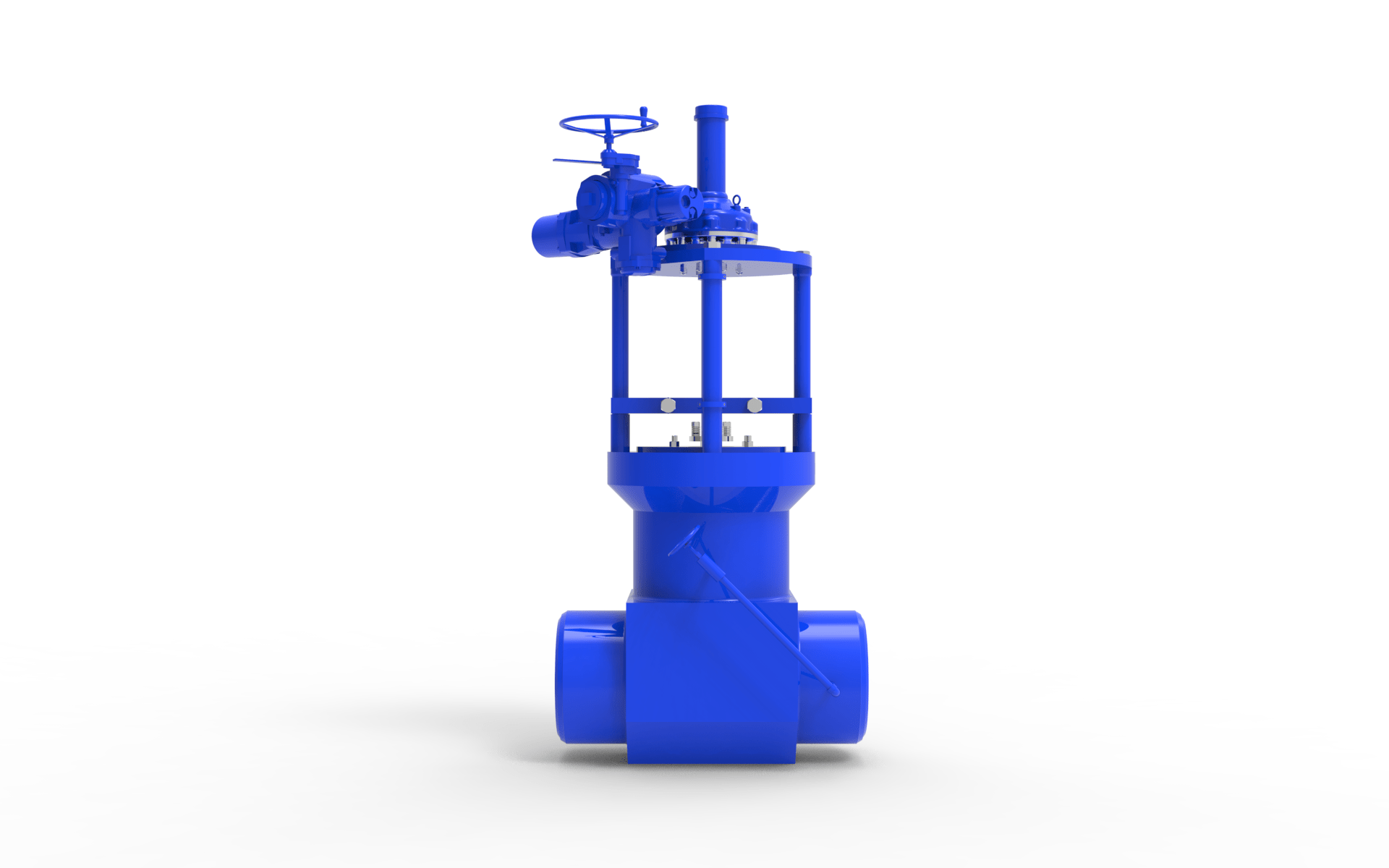

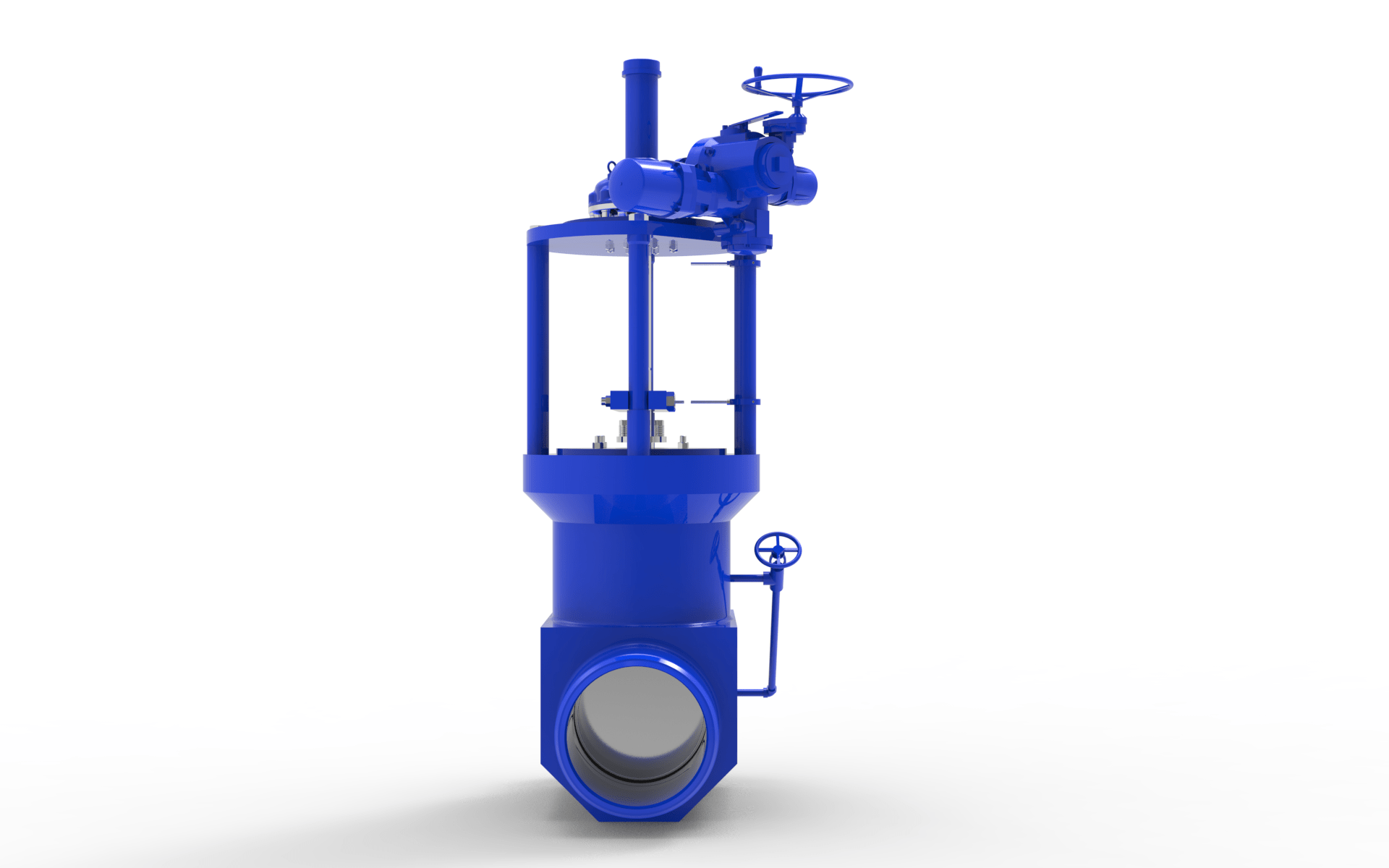

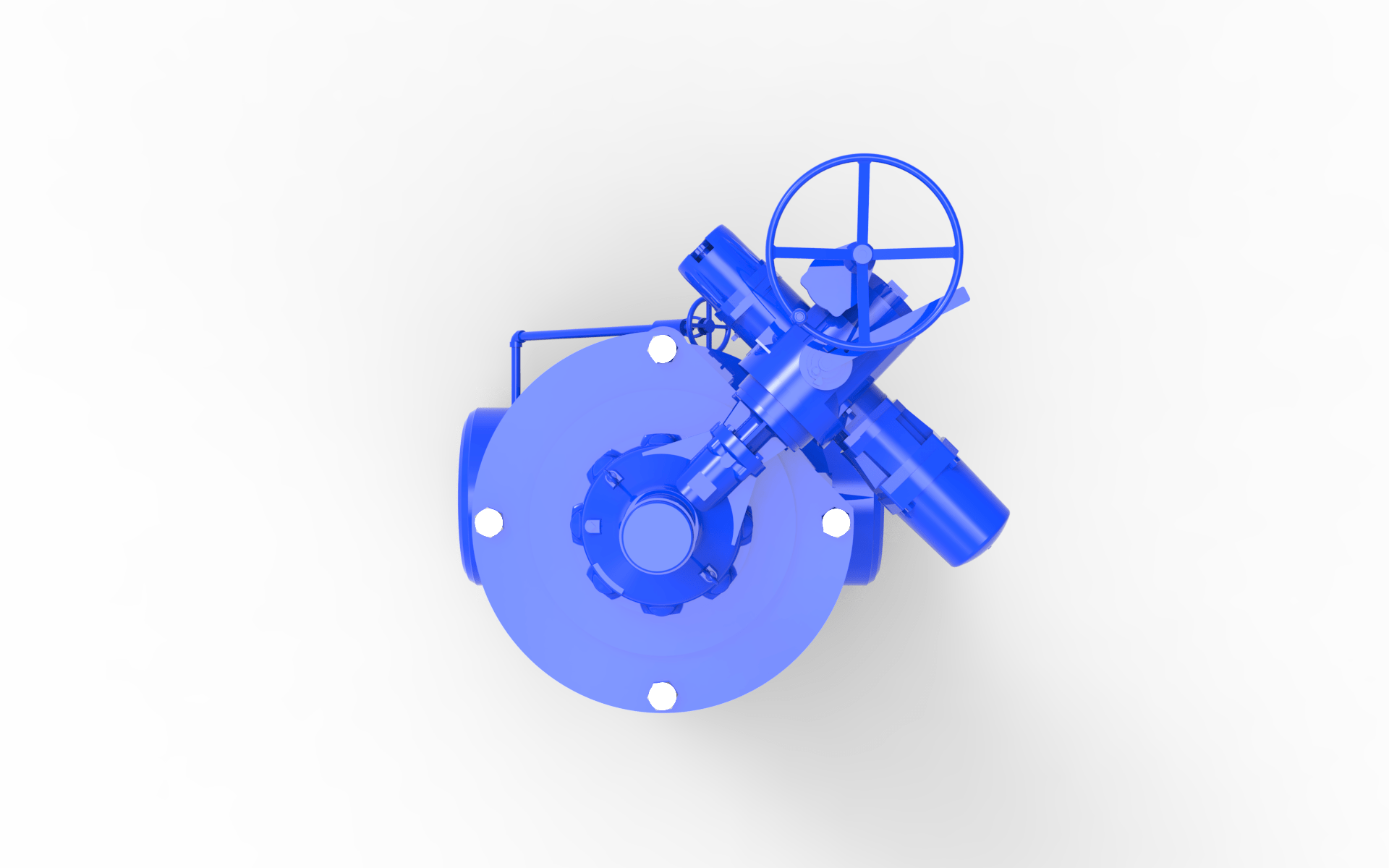

Atwood & Morrill®

Forged Parallel Slide Valves

KEY FEATURES & BENEFITS

-

Body: One piece forging to minimize material defects and deliver exceptional durability.

YOKE ROD UPPER STRUCTURE

-

Provides easy access to packing gland and rigid support for operator.

INDEPENDENT DISCS

-

Free to rotate and align with body seat rings, prevents thermal binding.

SEATING SURFACES

-

Alloy 6 on Inconel Butter Layer seating surfaces (seat rings and discs) provides superior bonding to the base material and supports a longer life.

SEATS

-

Wide, flat seating surfaces tolerate minor damage that can easily cause leakage in valves that utilize line contact seating.

APPLICATIONS

-

Main Steam Isolation

-

Hot Reheat Isolation

-

Other combined cycle, critical, super-critical, and ultra super critical steam applications.

DESIGN STANDARD

-

ASME B16.34

PRESSURE CLASS RANGE

-

ASME 600 to 2500

SIZE RANGE

-

6 - 30 inches (150 - 750 mm)

TEMPERATURE RANGE

-

Up to 1,200ºF

-

Up to 649ºC

MATERIALS

-

ASTM A105

-

A182 F11

-

F22

-

F91

END CONFIGURATION

-

Weld End