Loading 3D model...

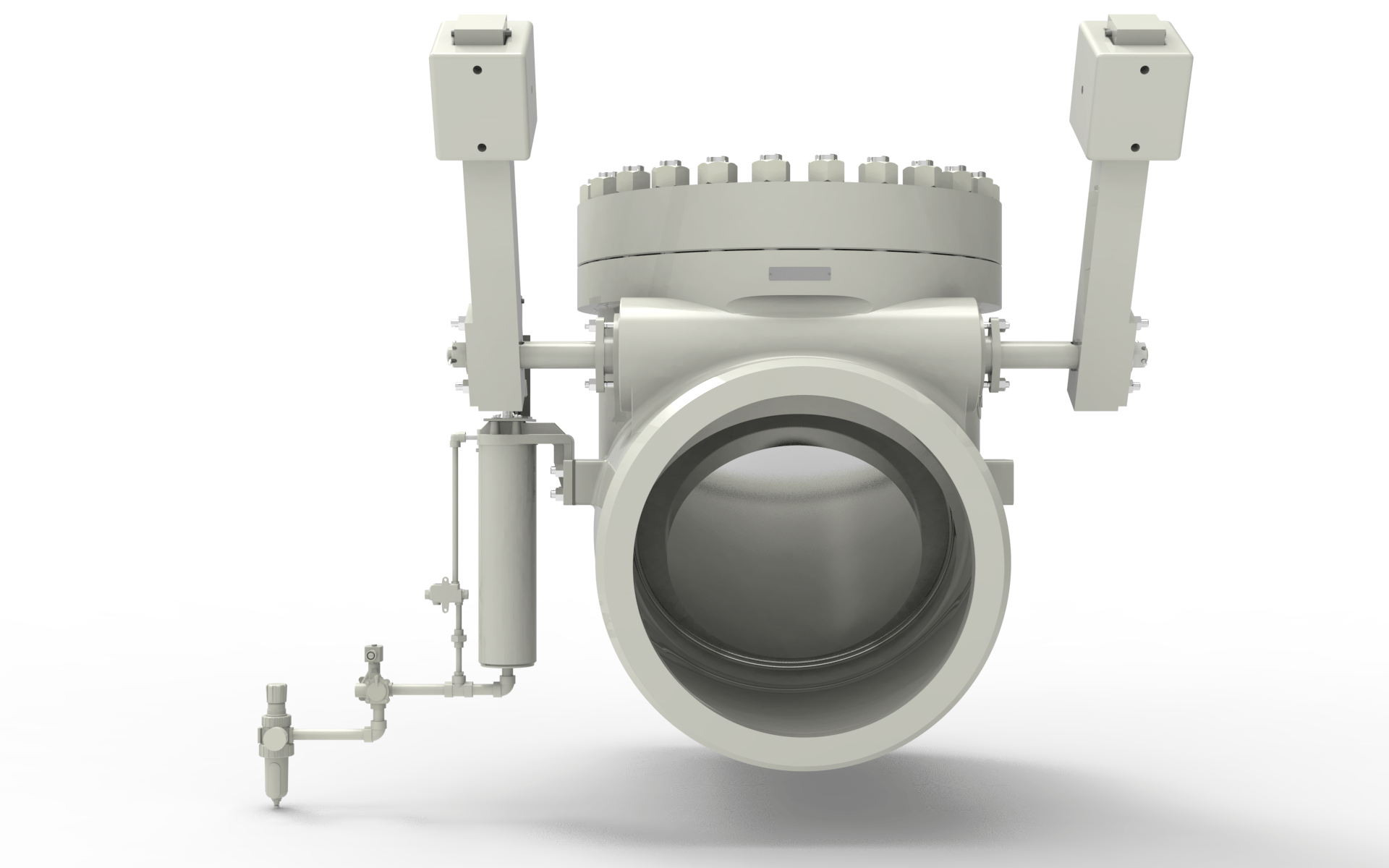

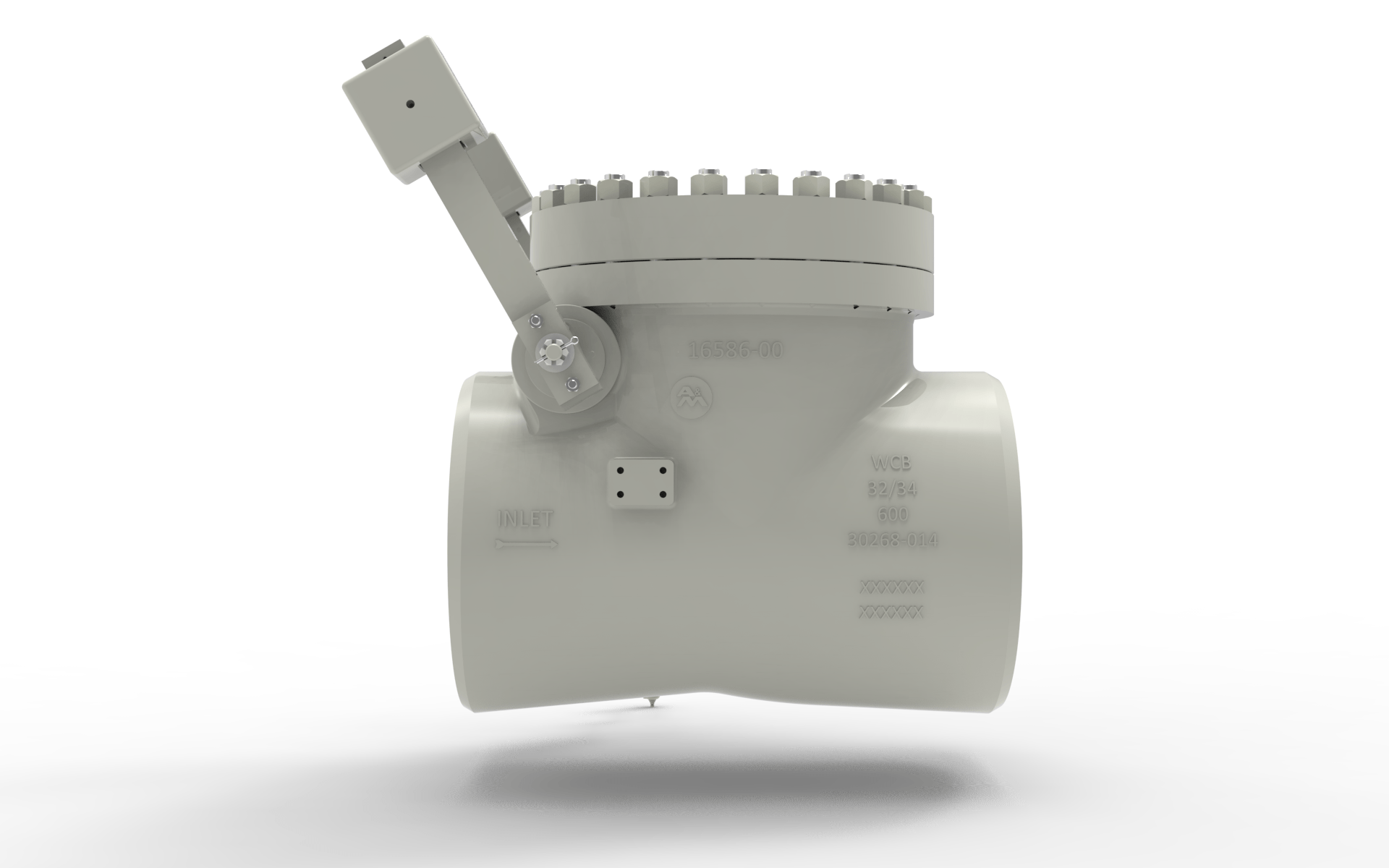

Atwood & Morrill®

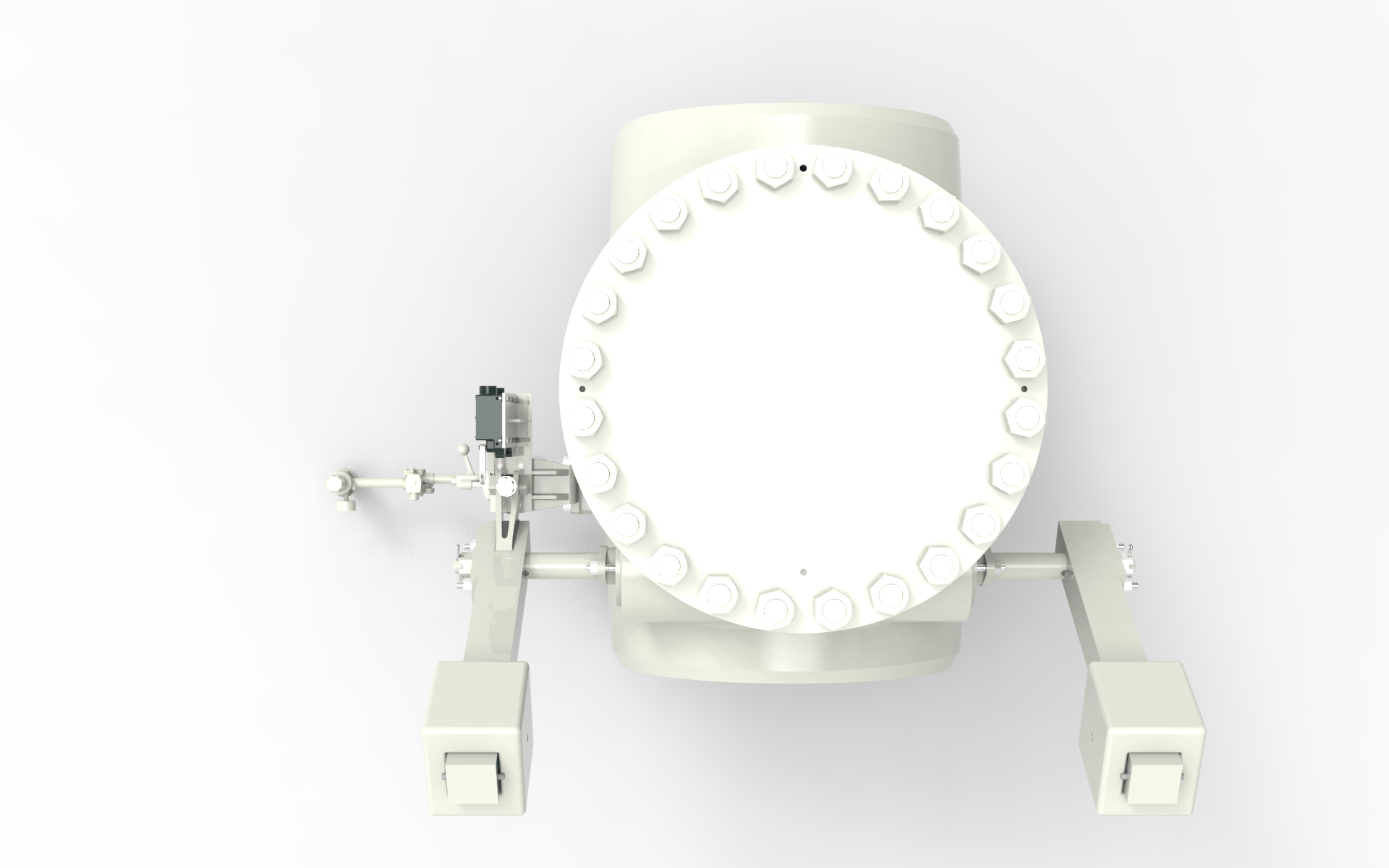

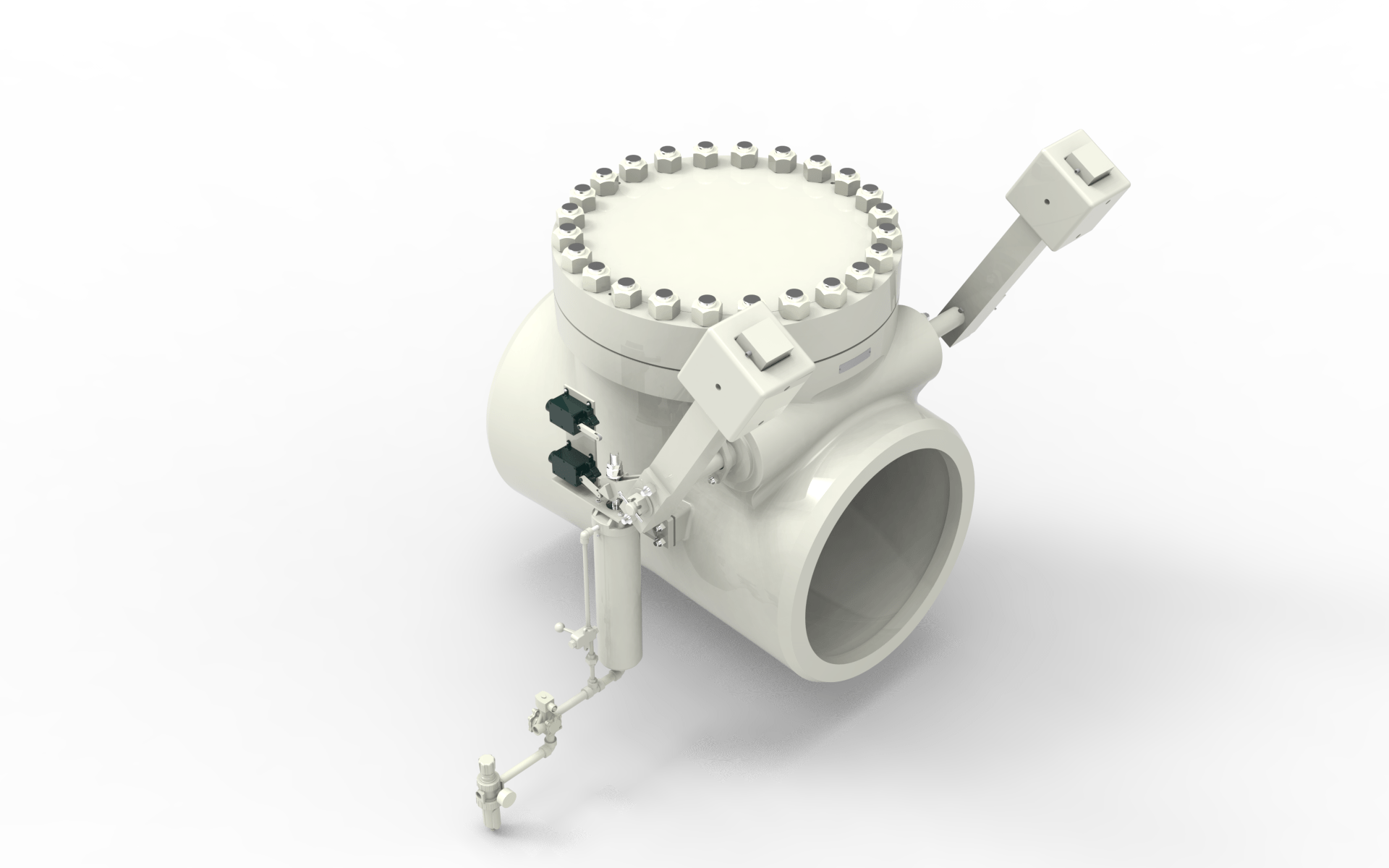

Cold Reheat Check Valve

Cold Reheat Check valves are designed to reliably protect the high pressure steam turbine from damage caused by reverse flow and bypass steam. The design prevents reheat steam from returning to turbine on trip and protects the high pressure turbine exhaust from bypass steam and water when the turbine bypass system operates.

KEY FEATURES & BENEFITS

-

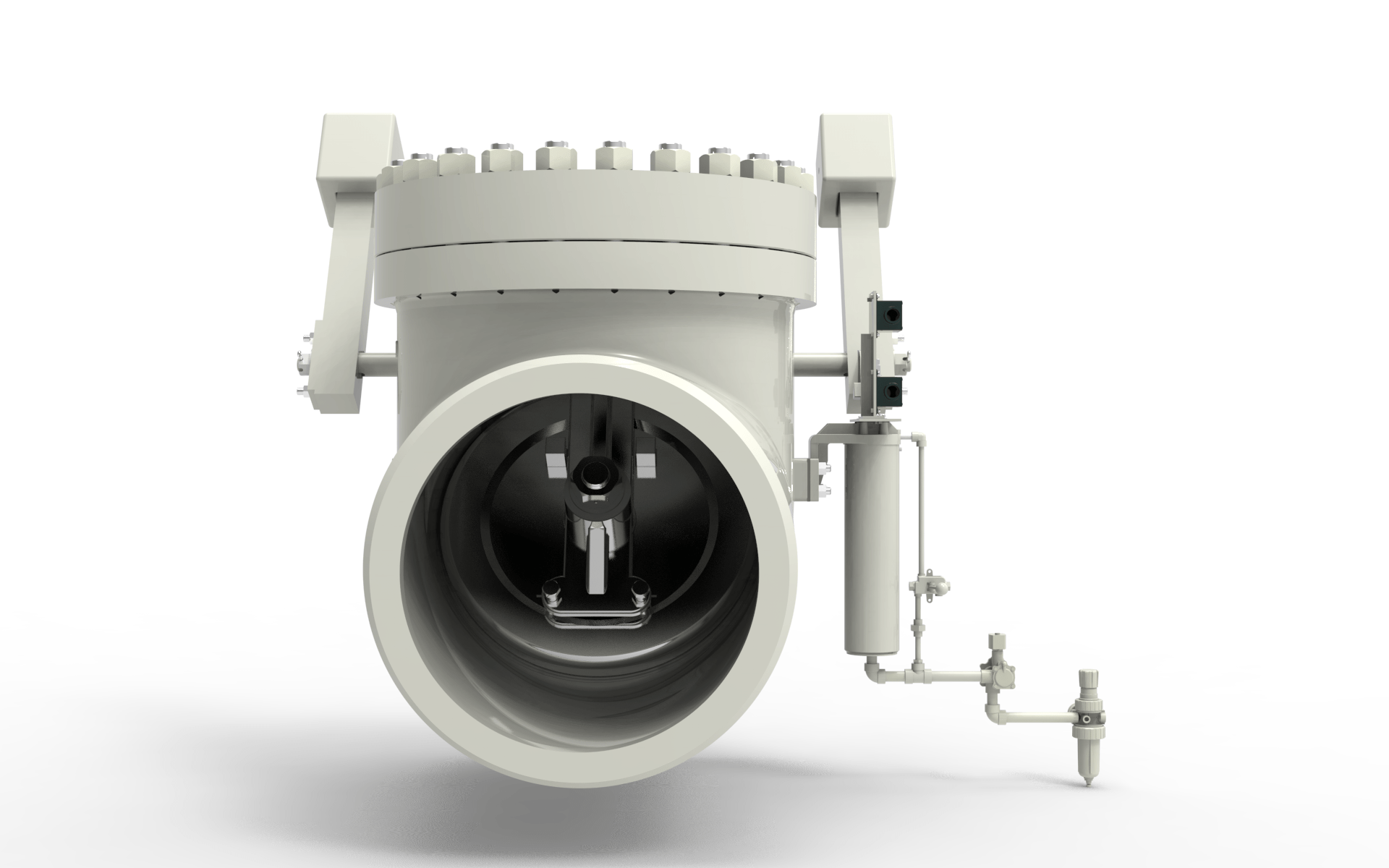

Proven swinging disc design

-

Inclined seat for short travel and quick operation

-

Wide, flat, non-jamming seats for tight seal

-

Streamlined flow passages for low pressure drop

-

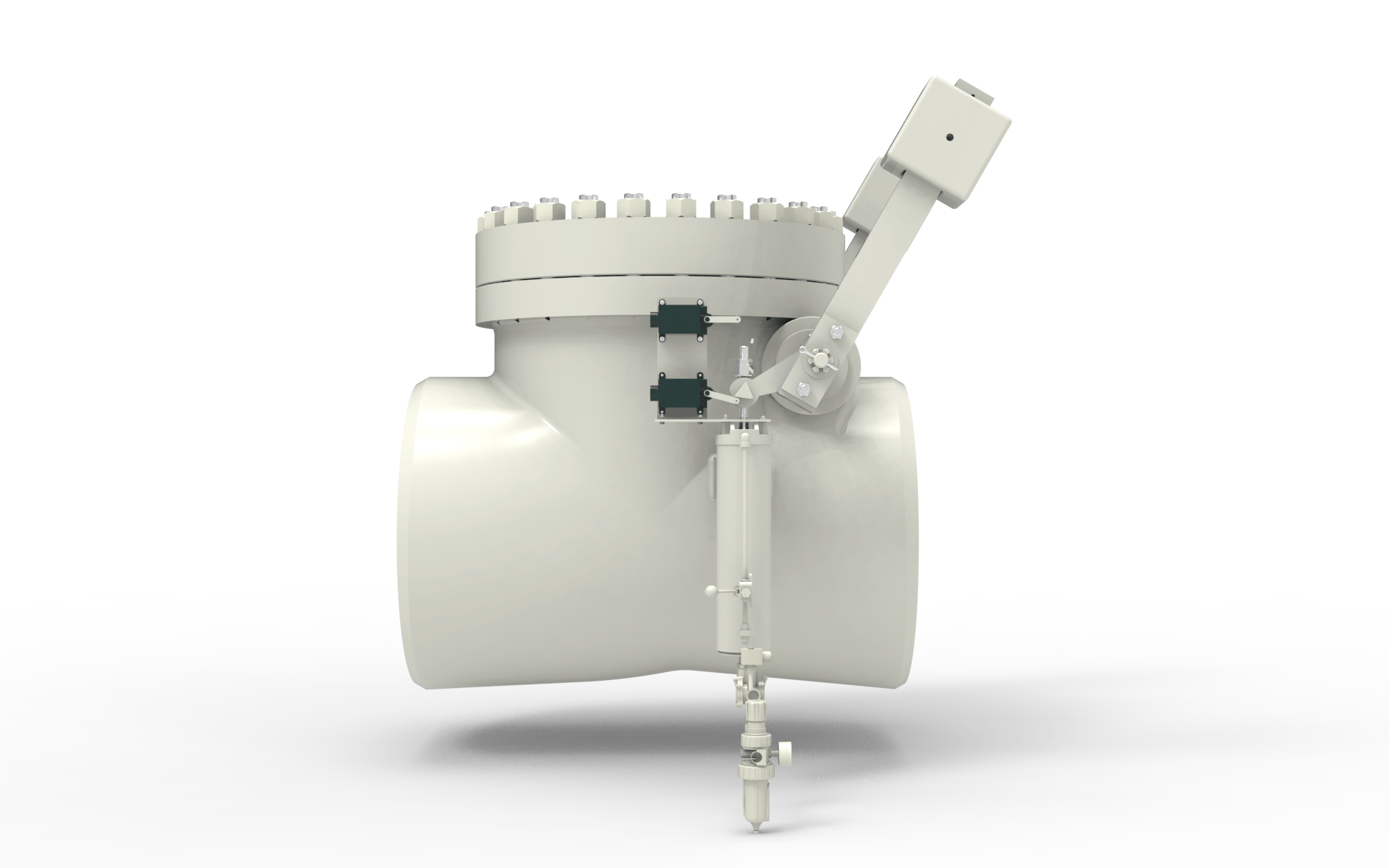

In-line maintenance through bolted top cover

-

Closing assist side mounted air cylinder

-

Capable of withstanding multiple rapid closures

PRESSURE CLASS RANGE

-

ASME Class 300 to 1500

MATERIALS

-

Carbon steel

-

Alloy steel

-

Stainless steel

UPGRADES & ADAPTATIONS

-

Air filter regulator

-

Double acting air cylinder

-

Limit switches

-

Live loaded packing

-

Mechanical position indication

-

Position transmitter

-

Protective guards for levers and weights

-

Proximity switches

-

Solenoid valves

APPLICATIONS

-

Cold Reheat Steam

DESIGN STANDARD

-

ASME B16.34

SIZE RANGE

-

16 – 42 inches (400 – 1050 mm)

-

Additional sizes available upon request.

TEMPERATURE RANGE

-

Up to 1,200ºF (649°C)

END CONFIGURATION

-

Weld End

-

Flanged