Loading 3D model...

Blakeborough®

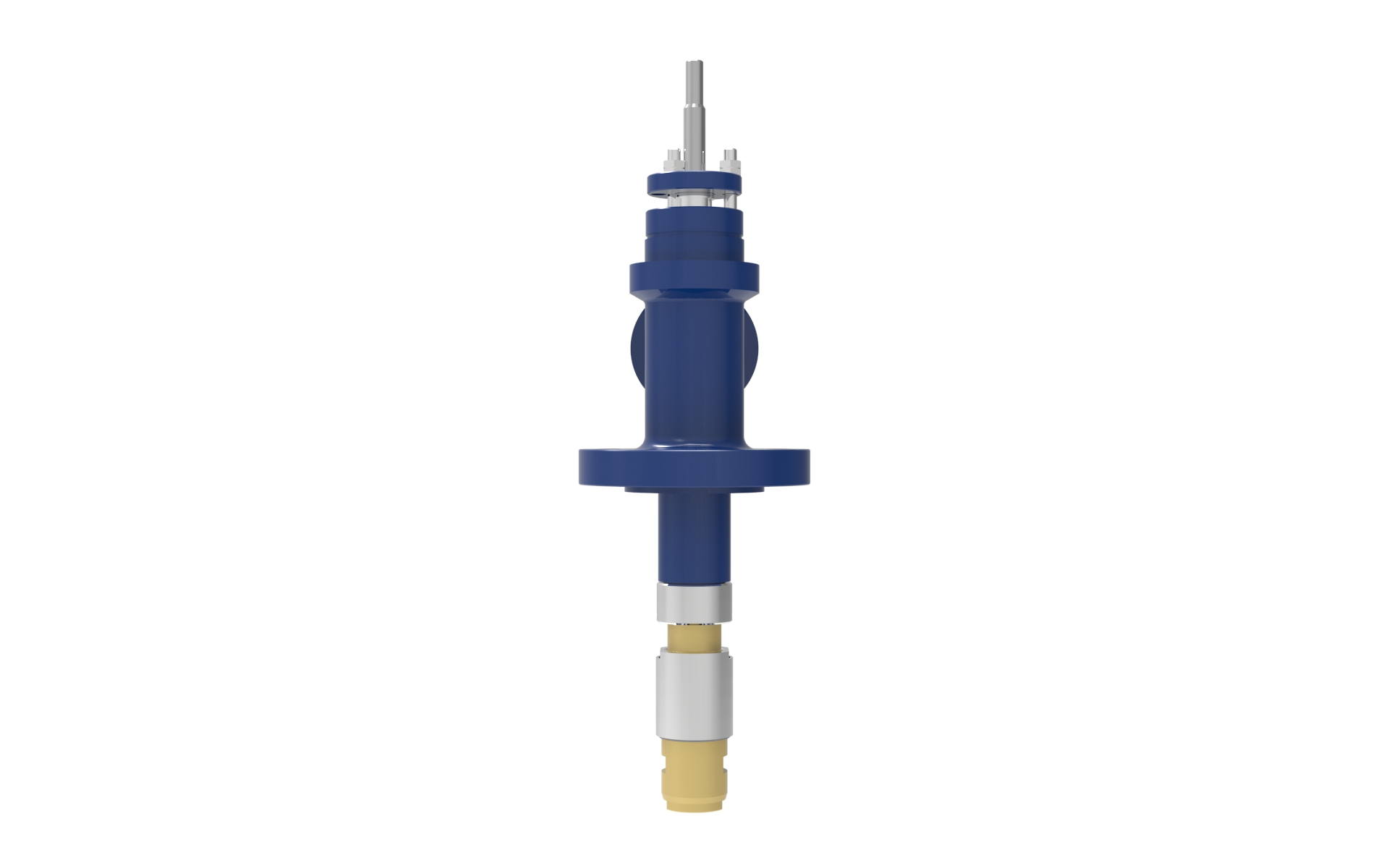

BV985 Desuperheater

Our multi-nozzle desuperheater design is proven in thousands of installations. The Blakeborough® BV985 offers increased CV ratings and improved rangeability with options of modified characteristics.

The BV985 spray nozzle is used on applications where high rangeability is required with direct control across the spray nozzle.

The Blakeborough® BV985 is designed so that steam is injected into the center of the pipe resulting in minimum droplet contact against the pipe walls. Water is injected across a series of 12 variable area nozzles which atomizes the water into micro fine droplets resulting in faster absorption rates and shorter outlet steam pipe lengths.

The amount of water injected into the pipe is directly controlled by the valve plug which is in turn controlled by the actuator. Where the pressure differential between the cooling medium and the vapor exceeds 60 bar, a two stage nozzle is available that extends the available pressure drop range to 100 bar. The two stage nozzle ensures erosion across the valve plug is minimized.

The BV985 spray nozzle is used on applications where high rangeability is required with direct control across the spray nozzle.

The Blakeborough® BV985 is designed so that steam is injected into the center of the pipe resulting in minimum droplet contact against the pipe walls. Water is injected across a series of 12 variable area nozzles which atomizes the water into micro fine droplets resulting in faster absorption rates and shorter outlet steam pipe lengths.

The amount of water injected into the pipe is directly controlled by the valve plug which is in turn controlled by the actuator. Where the pressure differential between the cooling medium and the vapor exceeds 60 bar, a two stage nozzle is available that extends the available pressure drop range to 100 bar. The two stage nozzle ensures erosion across the valve plug is minimized.

KEY FEATURES & BENEFITS

-

Variable spray nozzle

-

12 spray nozzles spaced for optimum dispersion in the steam flow

-

Large range of design CV options

-

High rangeability

-

Superior pressure 1 - 50 bar (15 -740 psi)

-

Nozzle rangeability - up to 40:1, accurate control of steam temperatures without water droplet damage to pipe walls

-

Swirl chambers and conical nozzles for optimum atomization

-

Simple low cost inline maintenance, interchangeable nozzles

APPLICATIONS

-

Suitable to all temperature control applications

DESIGN STANDARDS

-

ANSI B16.34

DESIGN RATINGS

-

ANSI 150 to ANSI 2500

SIZE RANGE & DIMENSIONS

-

Pipe sizes 150mm (6 inches) and above

MATERIALS

-

Carbon Steel

-

Chrome Moly