Loading 3D model...

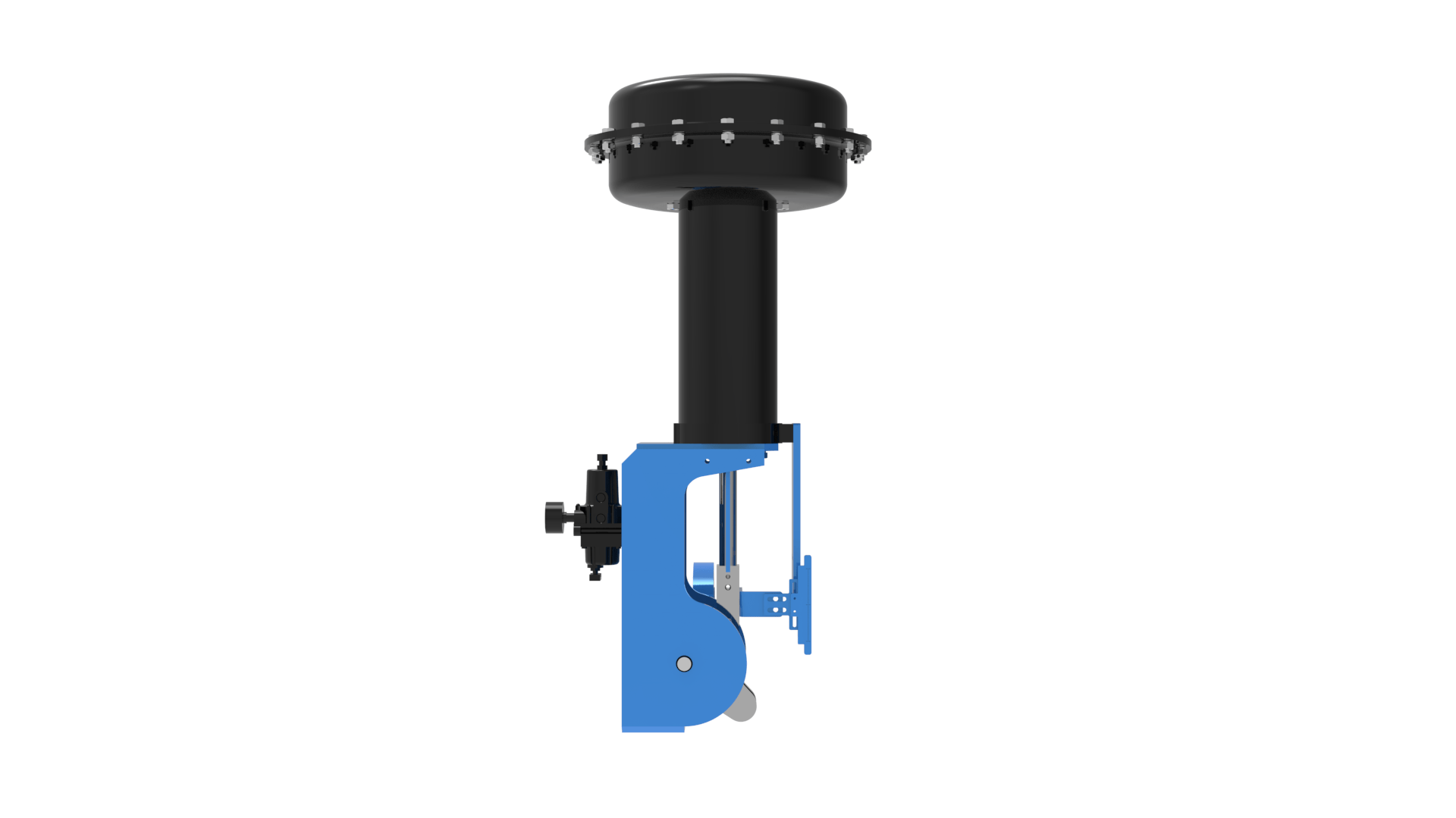

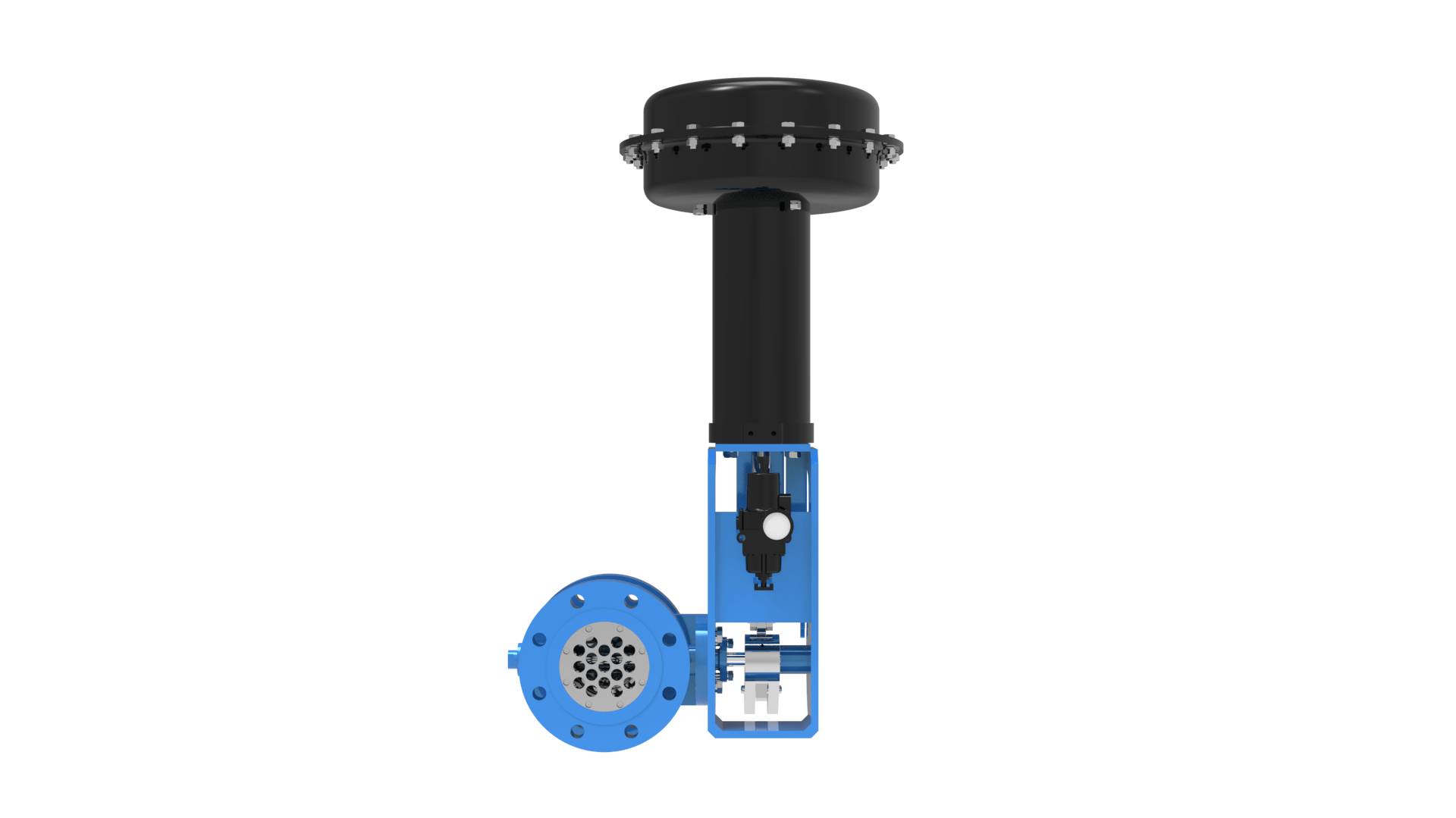

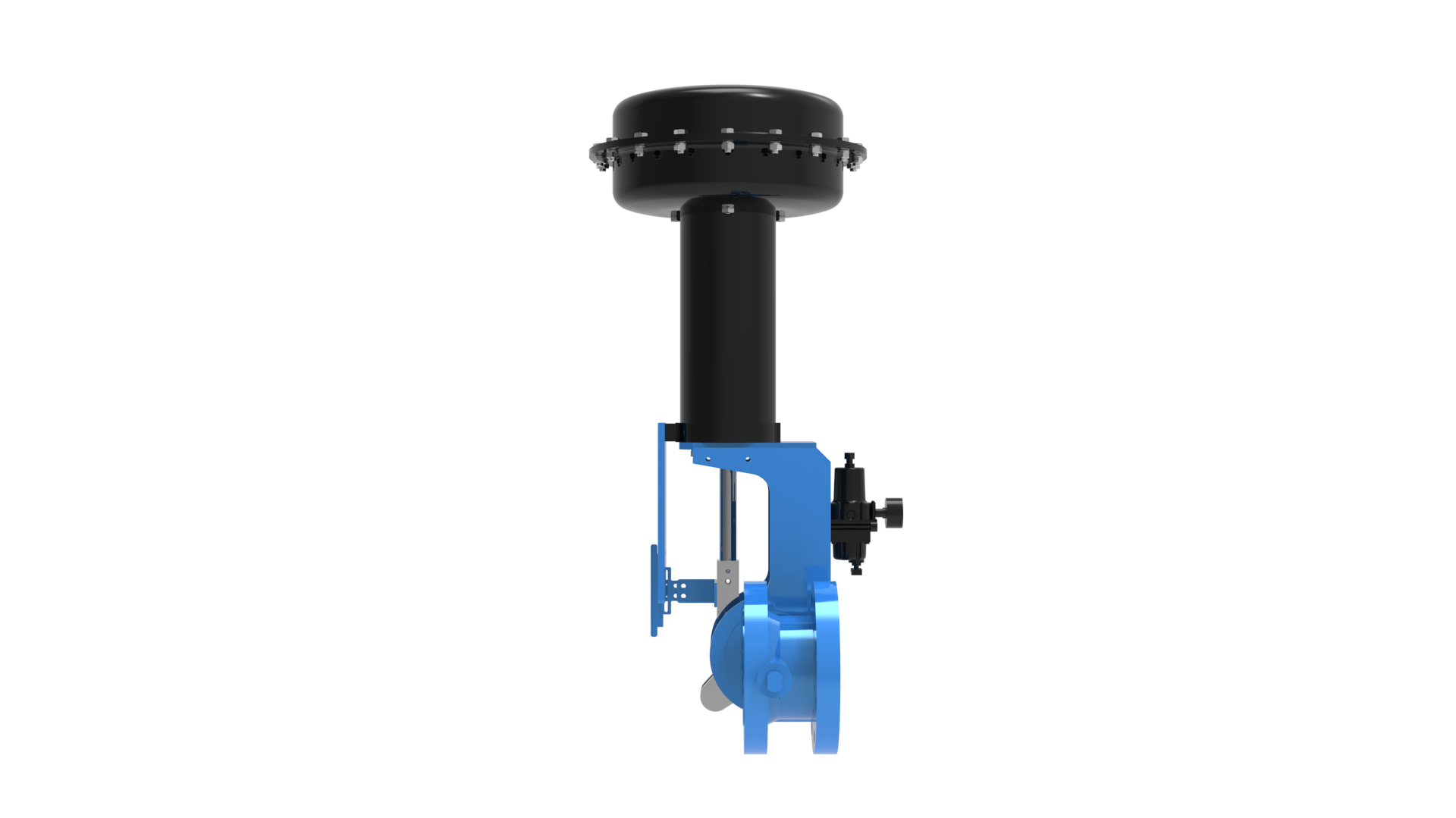

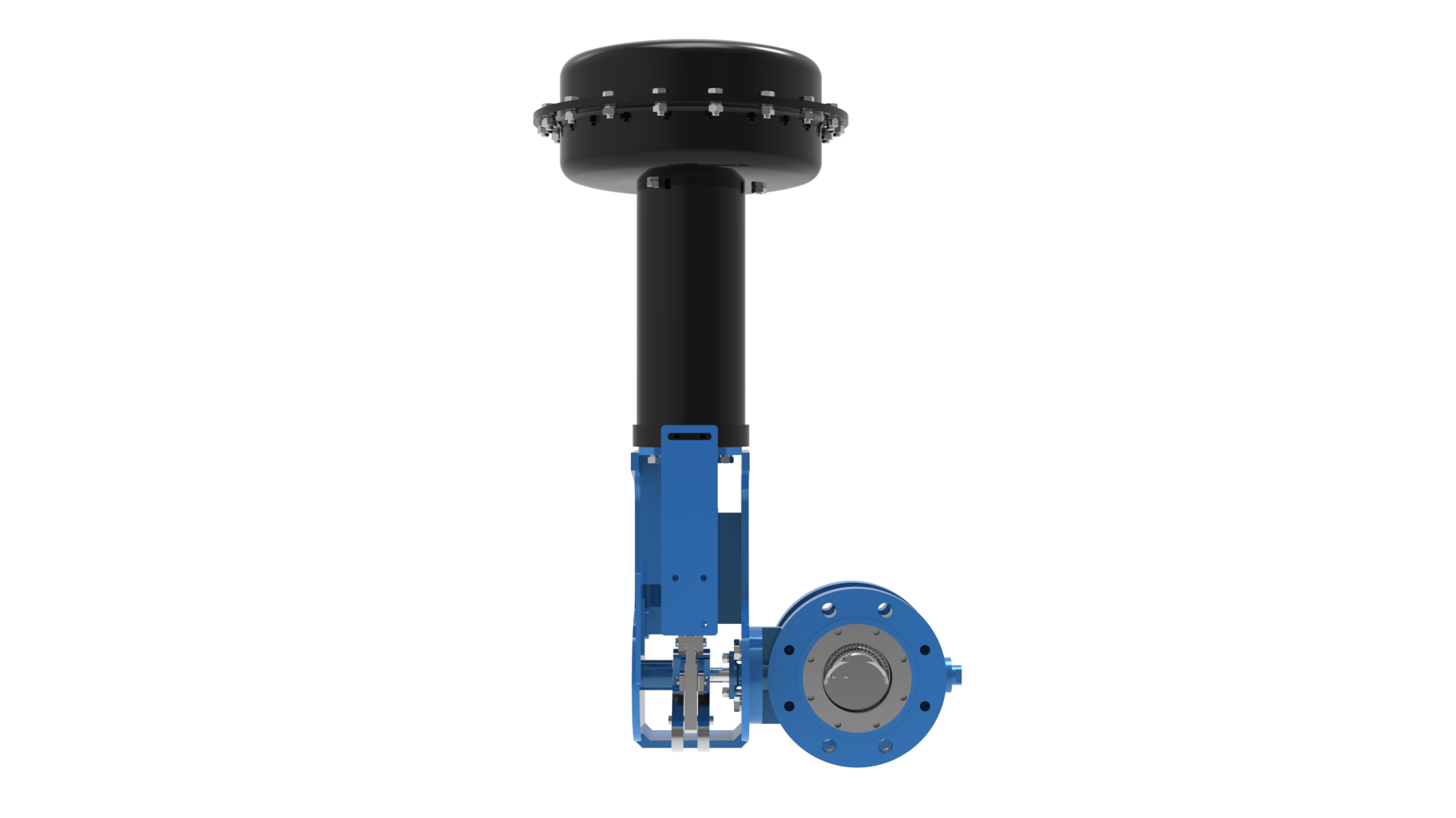

Batley Valve®

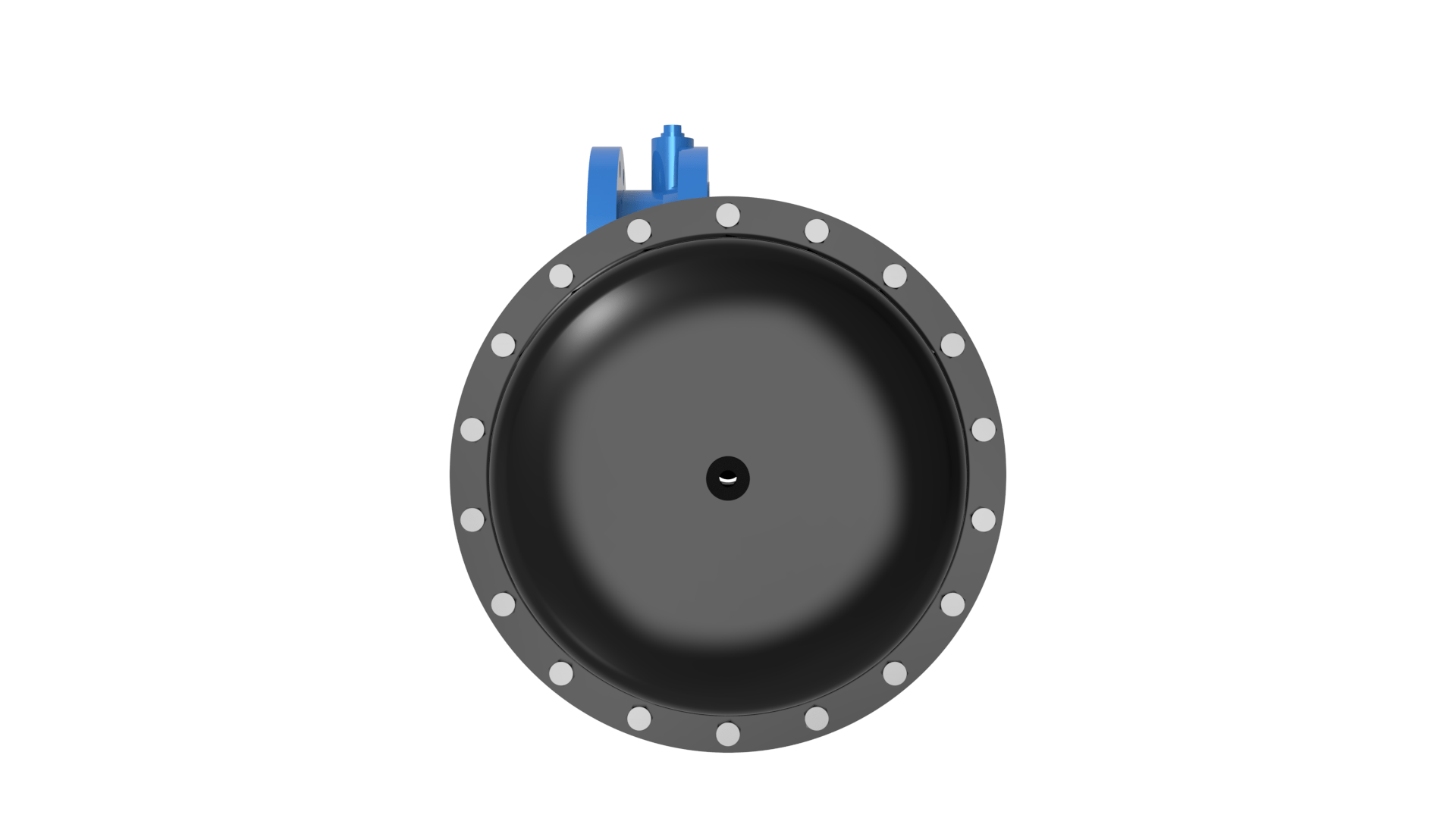

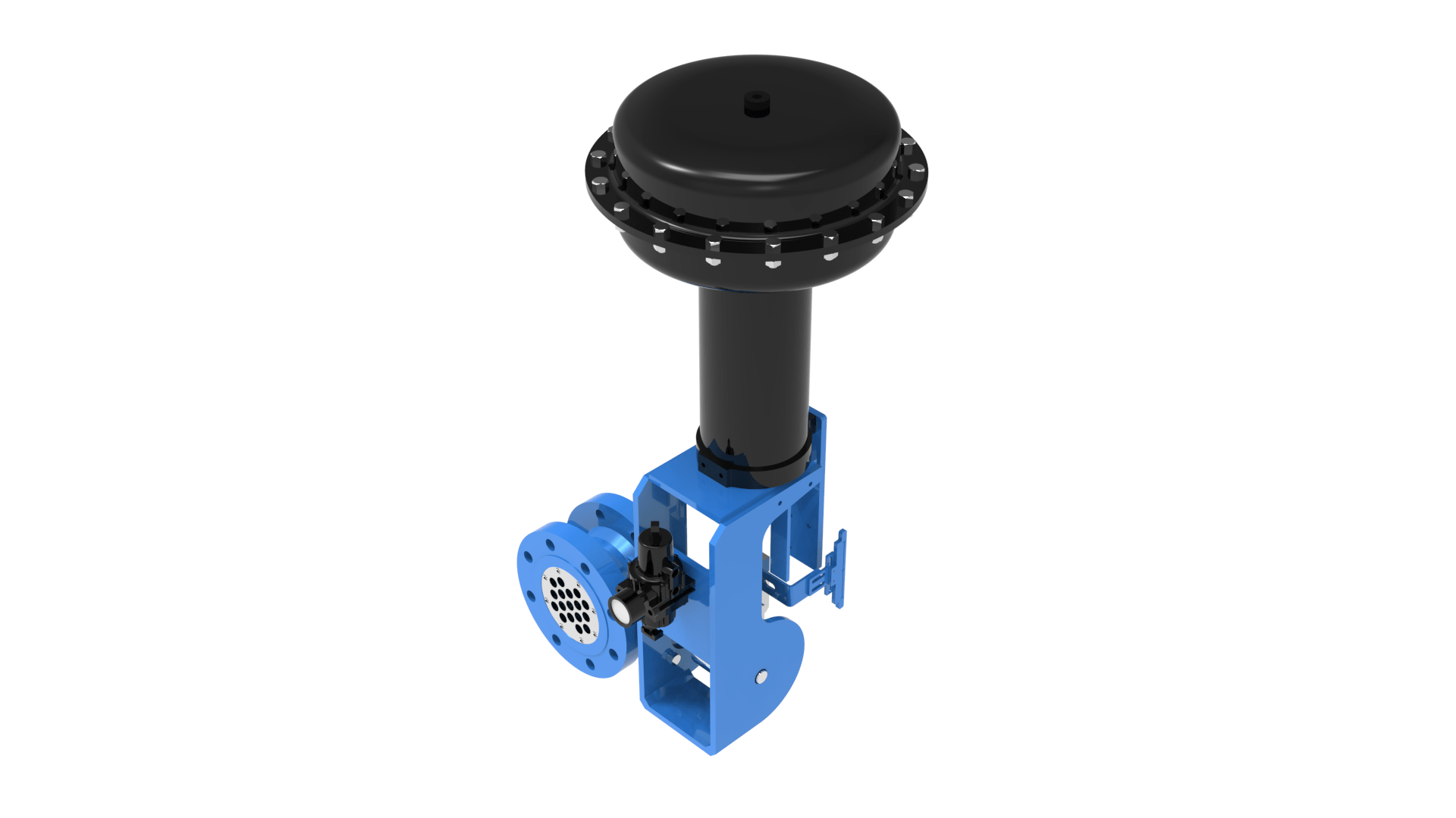

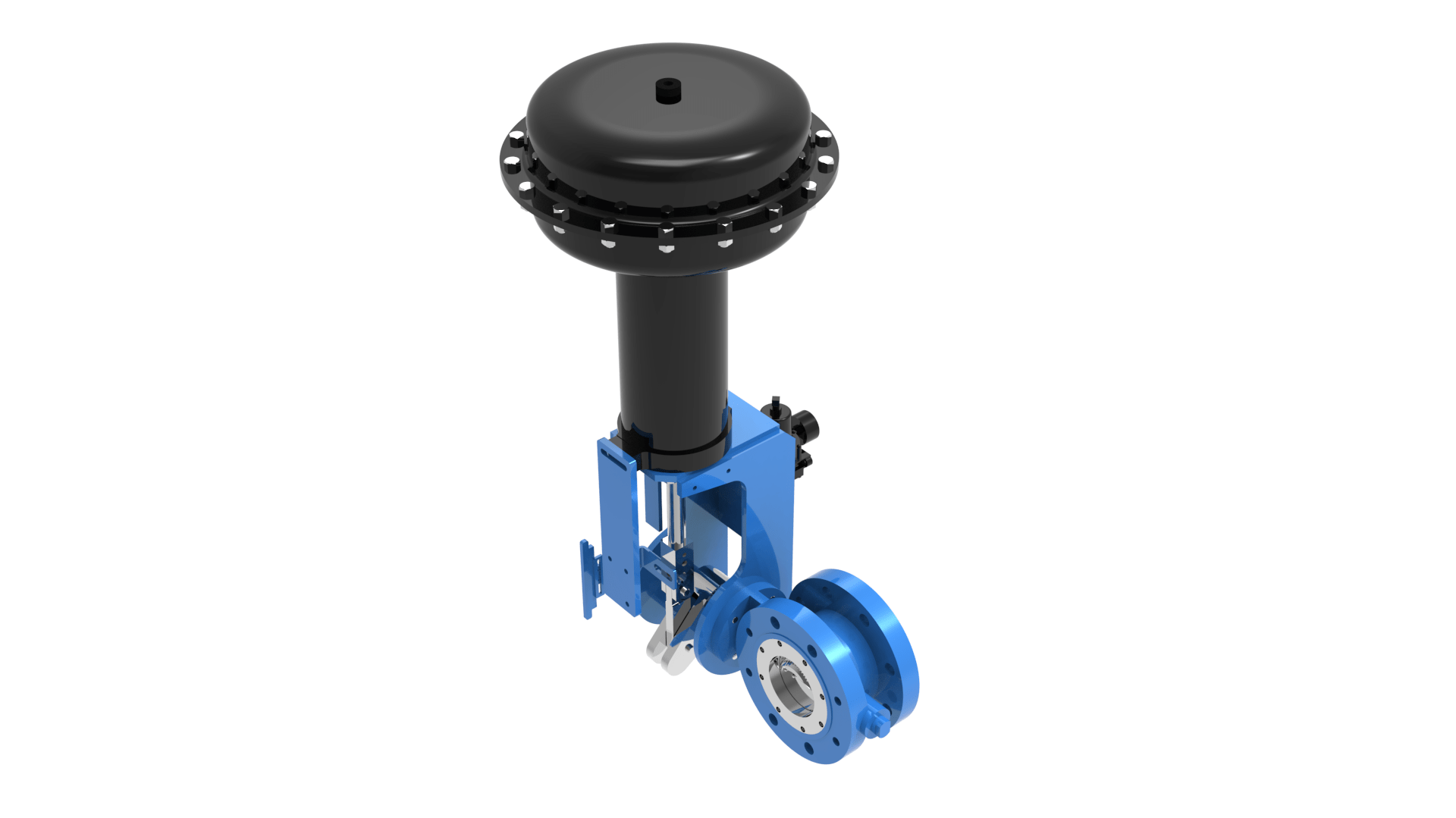

BV 26000 Metalseal

Double offset design and geometry of the valve and seal combine to ensure a uniform 360º seal contact in the closed position. The double eccentric action of the disc minimises wear and seating torque. Hard surface deposits such as hard Chrome plating, Stellite & Tungsten Carbide are available.

KEY FEATURES/BENEFITS

-

The Metalseal design suitable for high temperatures and abrasive service where a PTFE seal is not usable.

-

Valve is suitable for higher pressure and temperature than PTFE allows.

-

The vane’s streamlined design improves the flow line and reduces the head loss. ANSI Class IV leakage as standard. Special valves can be manufactured with Bodies drilled to suit flanges up to ANSI Class 2500lb. The valve can be supplied with Wafer, Lugged and Double Flanged bodies and incorporating full and reduced bore sizes to suit the application.

-

Seat design enables stable tight shut off performance both in direct and reverse flow conditions. Alternative seal retainer available to suit spiral wound gaskets. Sizes up to 1200mm on request. Butt weld body designs available on request.

TEMPERATURE RANGE

-

196ºC to 900ºC (-320ºF to 1652ºF)

ALL CASTABLE MATERIALS

-

Carbon Steel

-

Stainless Steel

-

Duplex

-

Super Duplex

-

Hastalloy

-

Inconel

-

Monel

-

Titanium

UPGRADES/ADAPTATIONS

-

Upgrade to leakage ANSI Class V

-

MSS SP61 & API 5 available

APPLICATIONS

-

Multipurpose Low, Medium and High pressure with Metal to Metal seal for high and very high temperature

-

Slurry services

DESIGN STANDARDS

-

API 609

-

BS 5155

-

MSS SP68

-

API 598

-

BS 6755

-

FCI 70.2

-

ASME B16.34

-

ISO 5752

-

DIN 3202

DESIGN RATINGS

-

ASME 150# to 2500#

SIZE RANGE/ DIMENSIONS

-

150mm to 1000mm (6" to 80")

TRIM MATERIALS

-

Austenitic SS

-

17-4 PH

-

Duplex/Super Duplex SS

-

Various hard surfaces to seat & seal ring available (stellite, tungsten carbide).