Loading 3D model...

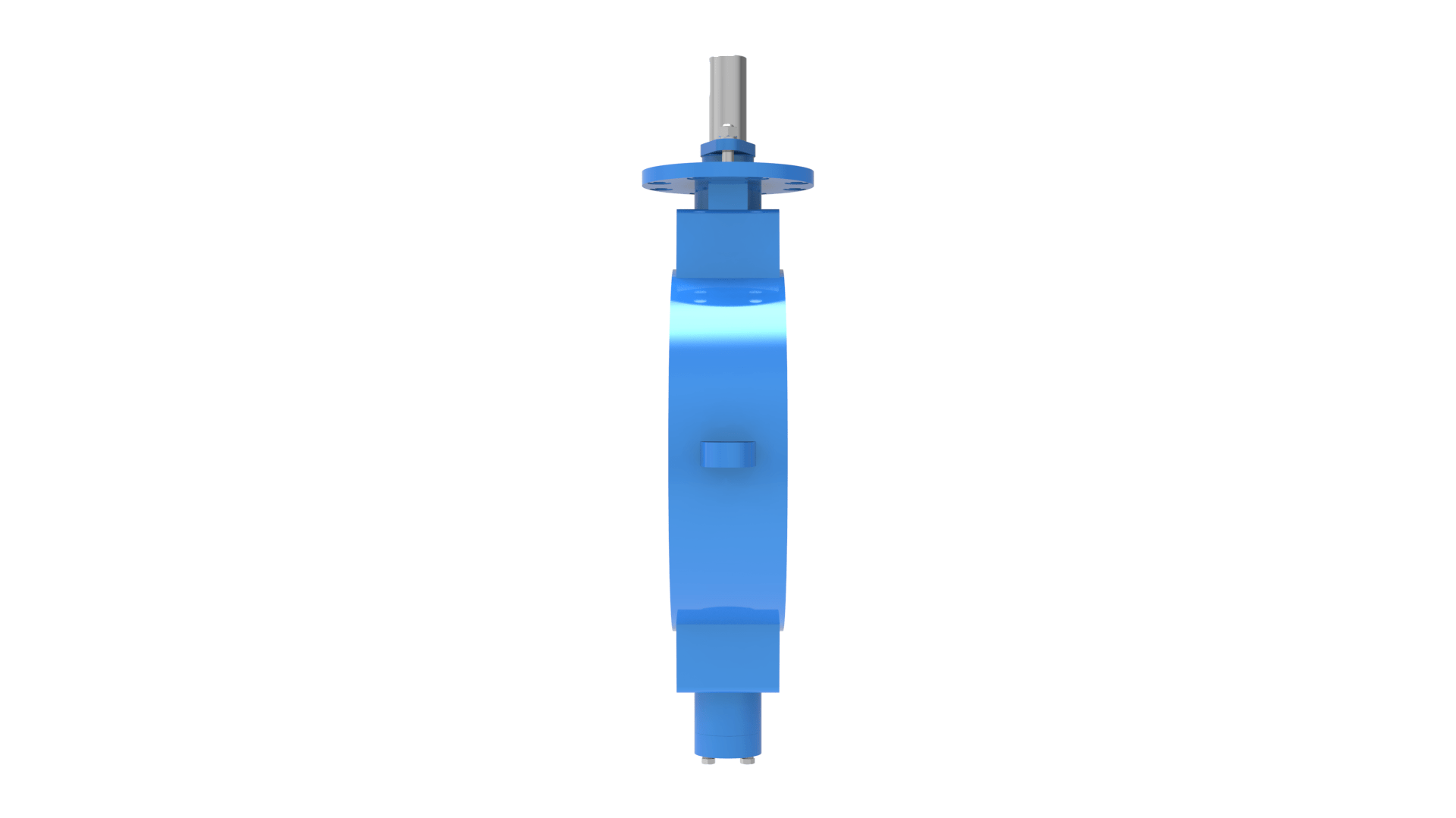

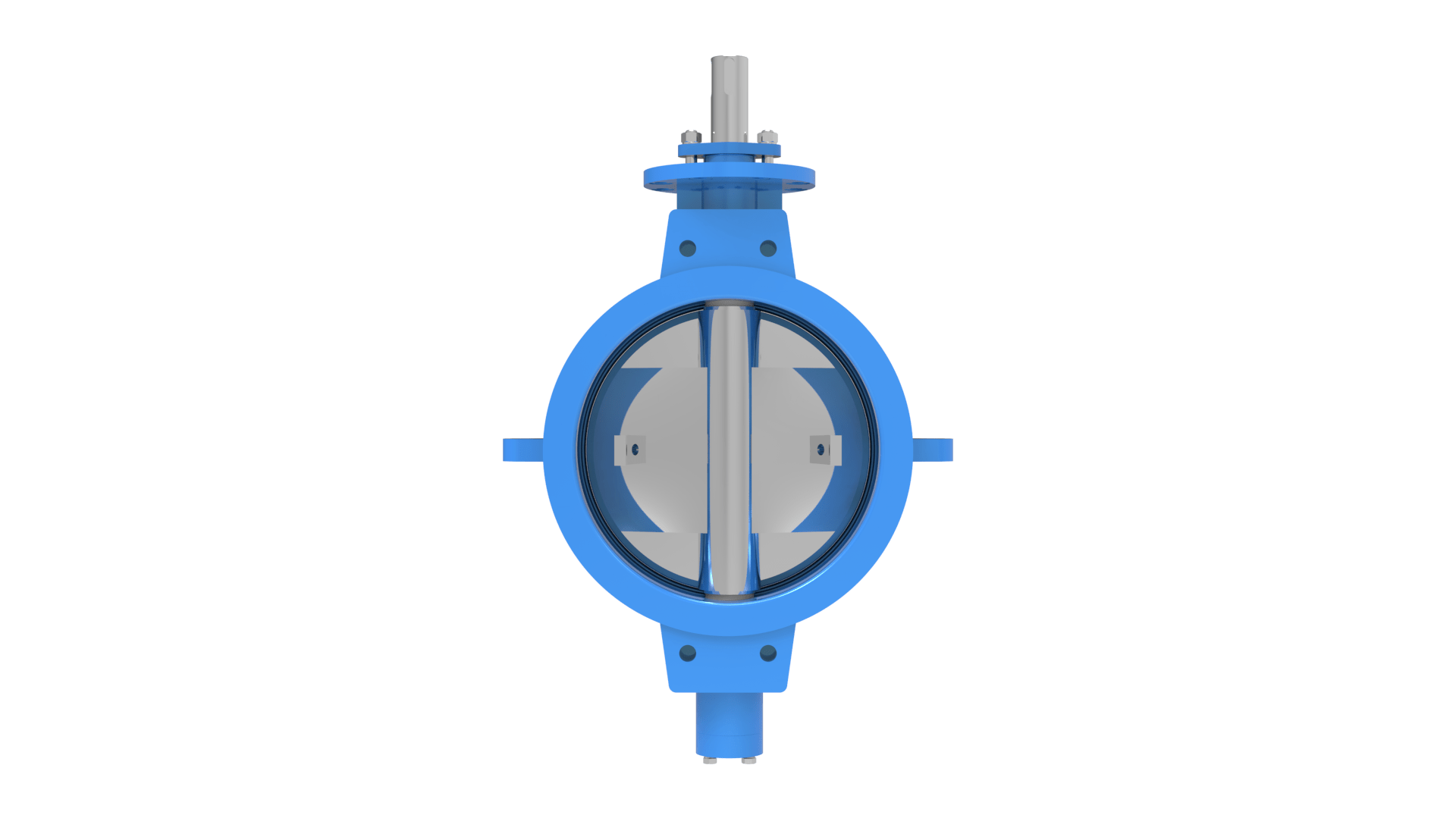

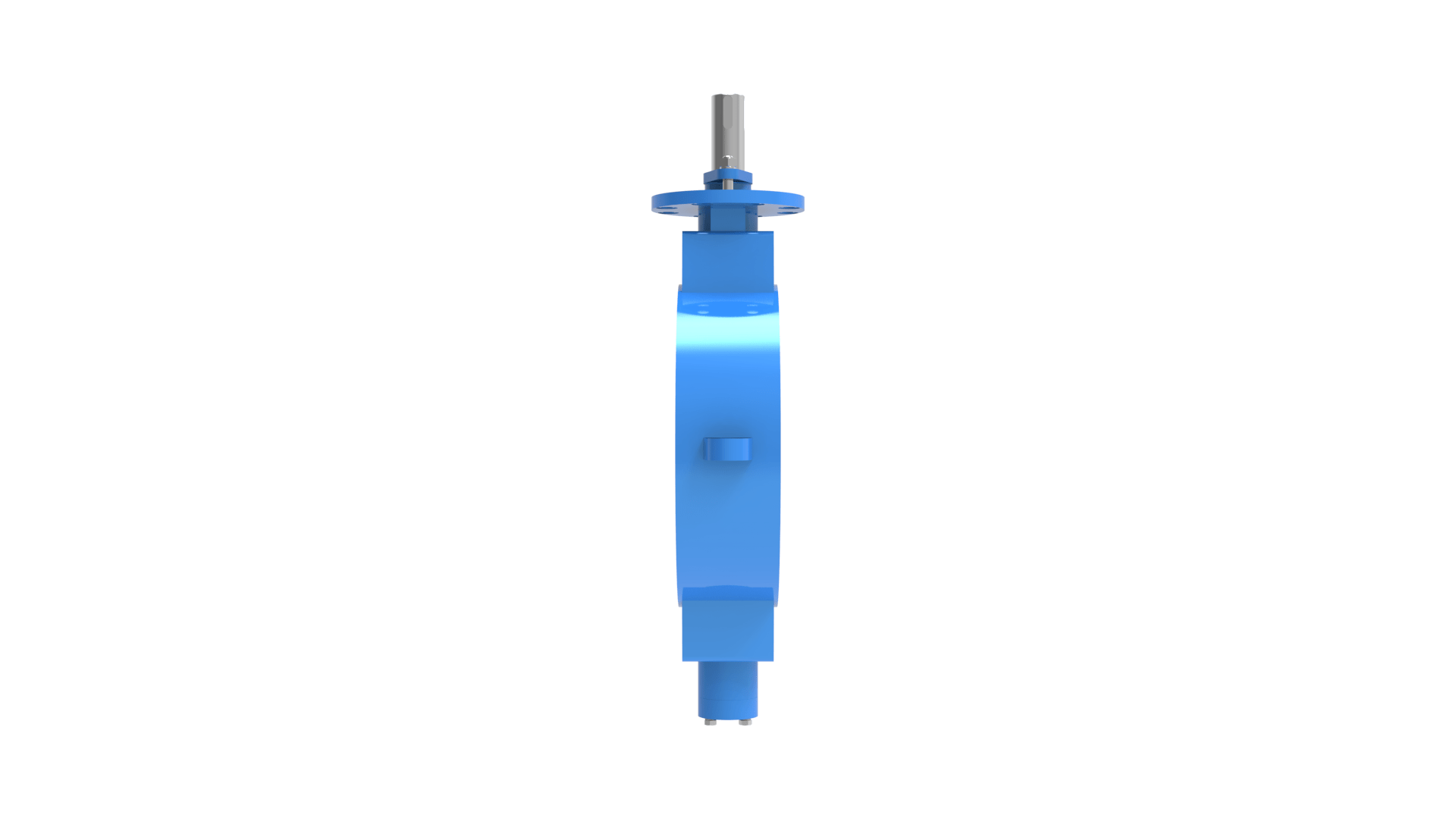

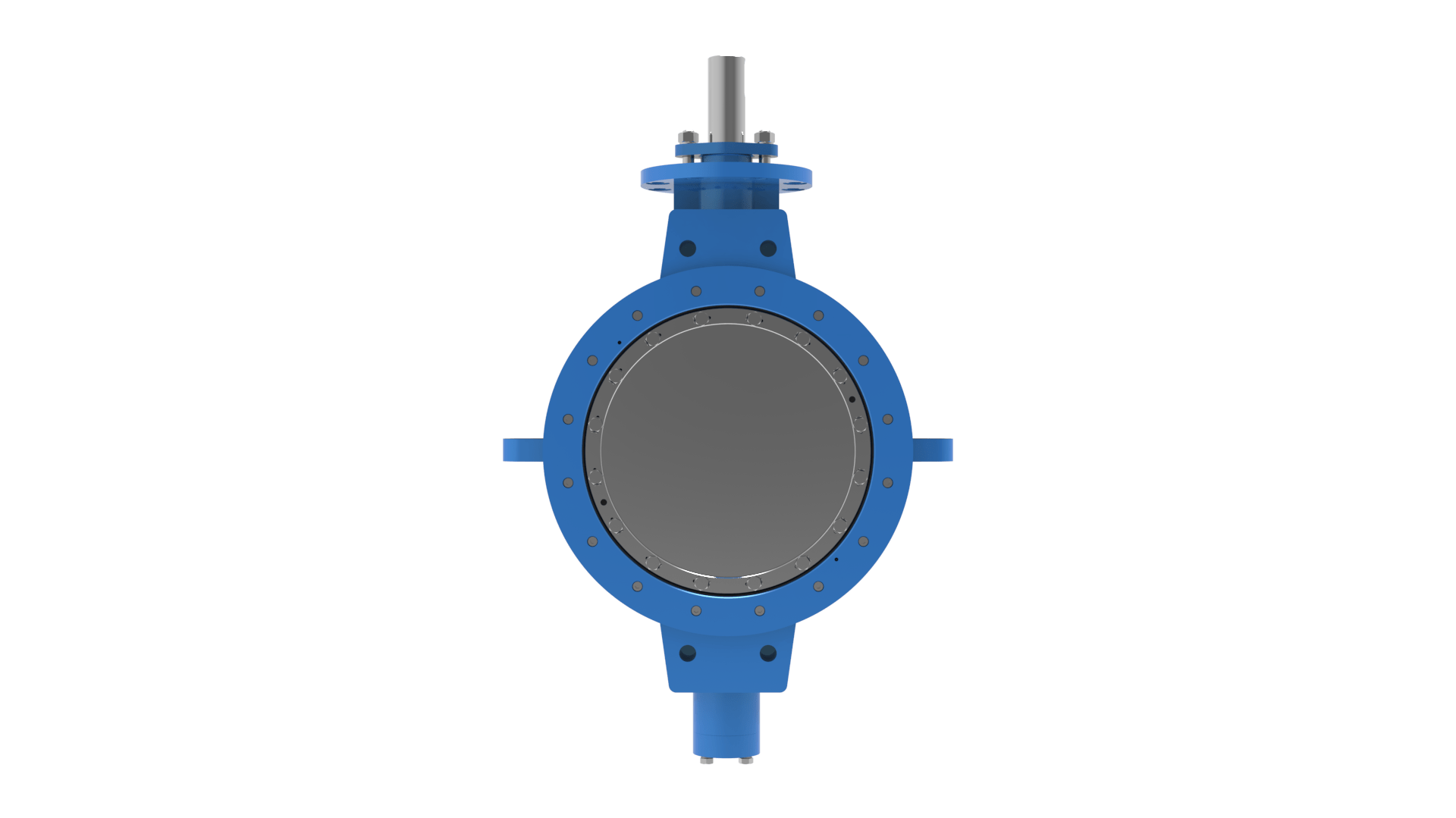

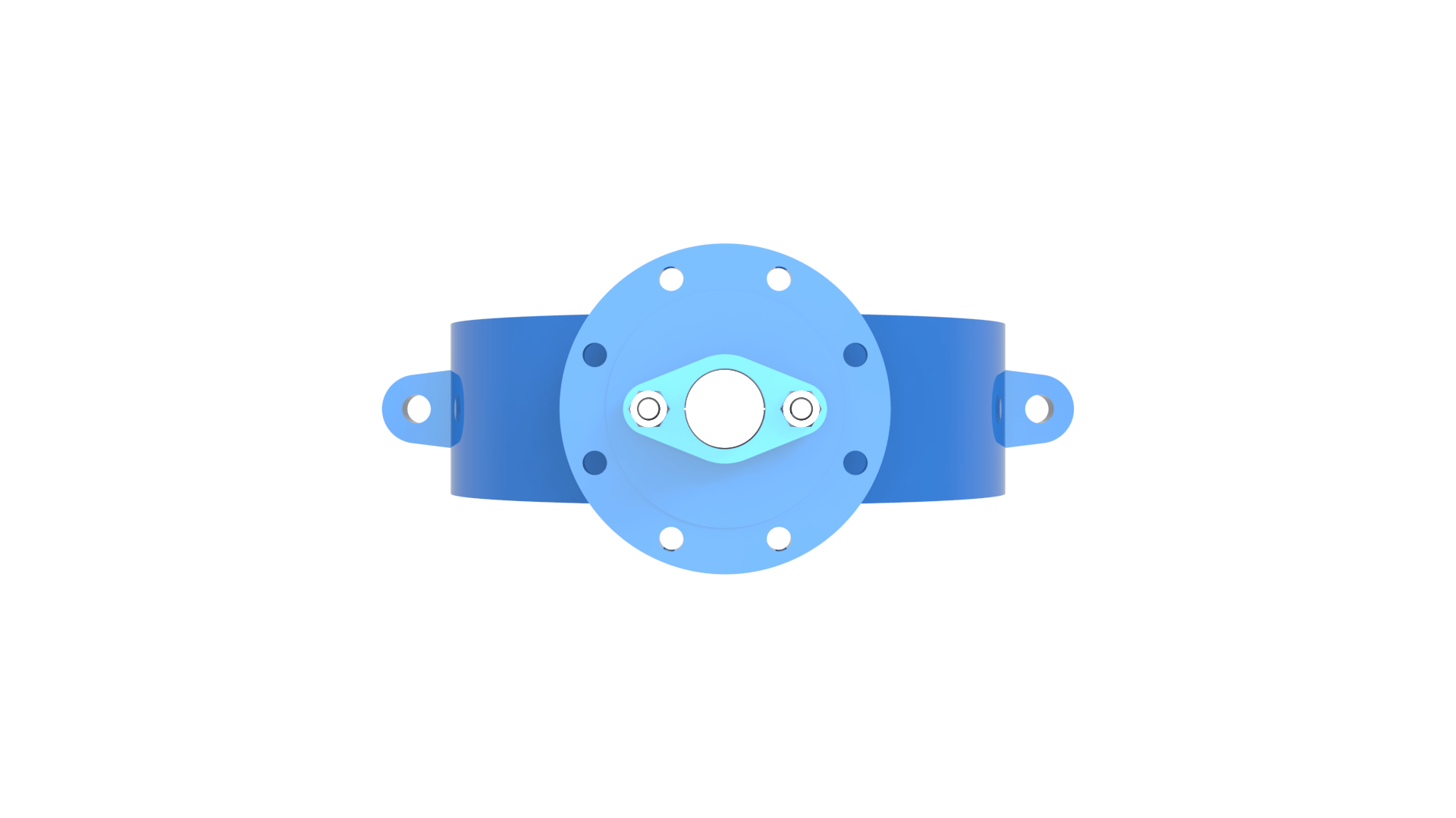

Batley Valve®

BV 20000 Steadseal

KEY FEATURES/BENEFITS

-

Double eccentric action moves the vane into and out of the seat with minimum wear and seating torque, giving longer seat life and reduced overall valve torque.

-

Valve Body in either Ductile Iron or Carbon Steel is protected with a number of different linings to suit each application.

-

Sealing Ring is easily replaceable. The valve is suitable for through-bolt mounting between flanges to BS4504, BS10, BS1560, ANSI or DIN. The vane’s streamlined design improves the flow line and reduces the head loss.

-

PTFE-faced self lubricating Glacier DU bearings are normally fitted and adequately provide for the high loading, low friction requirements.

-

Stainless steel seat are provided for general applications but for strictly noncorrosive services such as clean air, body bore is coated with an anti-corrosive surface treatment. The resilient seat is an high-quality nitrile rubber ring attached with the vane edge with a steel clamping ring.

-

Alternative seals are viton, butyl, neoprene, ethylene propylene.

ALL CASTABLE MATERIALS

-

Carbon Steel

-

Stainless Steel

-

Duplex

-

Super Duplex

-

Hastalloy

-

Inconel

-

Monel

-

Titanium

TRIM MATERIALS

-

Austenitic SS

-

17-4 PH

-

Duplex /Super Duplex SS

-

Various hard surfaces to seat & seal ring available (stellite, tungsten carbide)

APPLICATIONS

-

Corrosive service with low and medium temperature service

-

Desalination and Water treatment

-

Chemical plant

DESIGN STANDARDS

-

BS4504

-

BS10

-

BS1560

-

ANSI

-

DIN

-

AWWA C504

-

MSS SP67

DESIGN RATINGS

-

ASME 150, 300

SIZE RANGE/ DIMENSIONS

-

100 to 2000mm (4"" to 80"")

TEMPERATURE RANGE

-

30ºC up to 200ºC (86ºF to 392ºF)

UPGRADES/ADAPTATIONS

-

Material Reinforced Aluminium/Bronze

-

Glass Flake coating

-

Rubber lining