Loading 3D model...

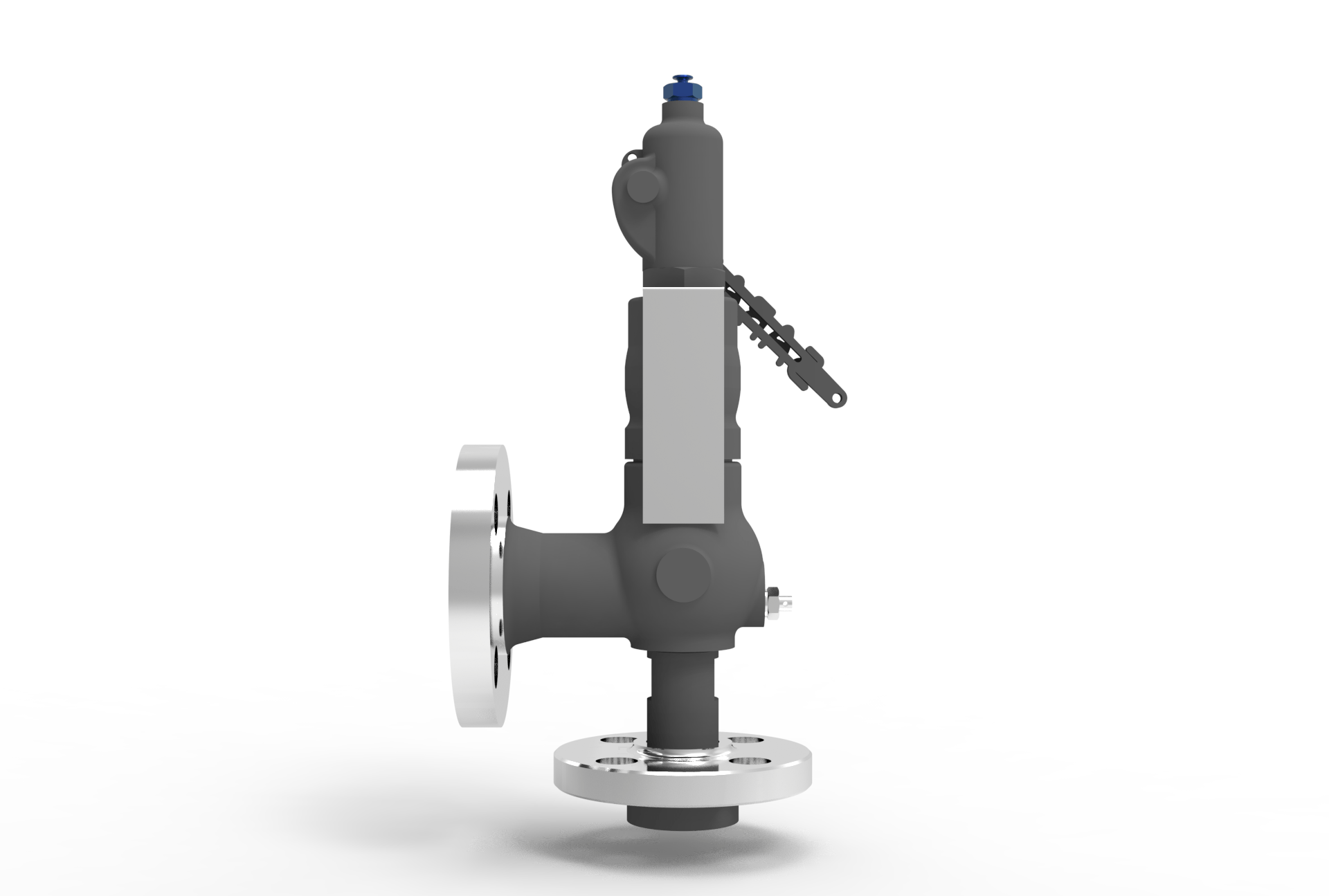

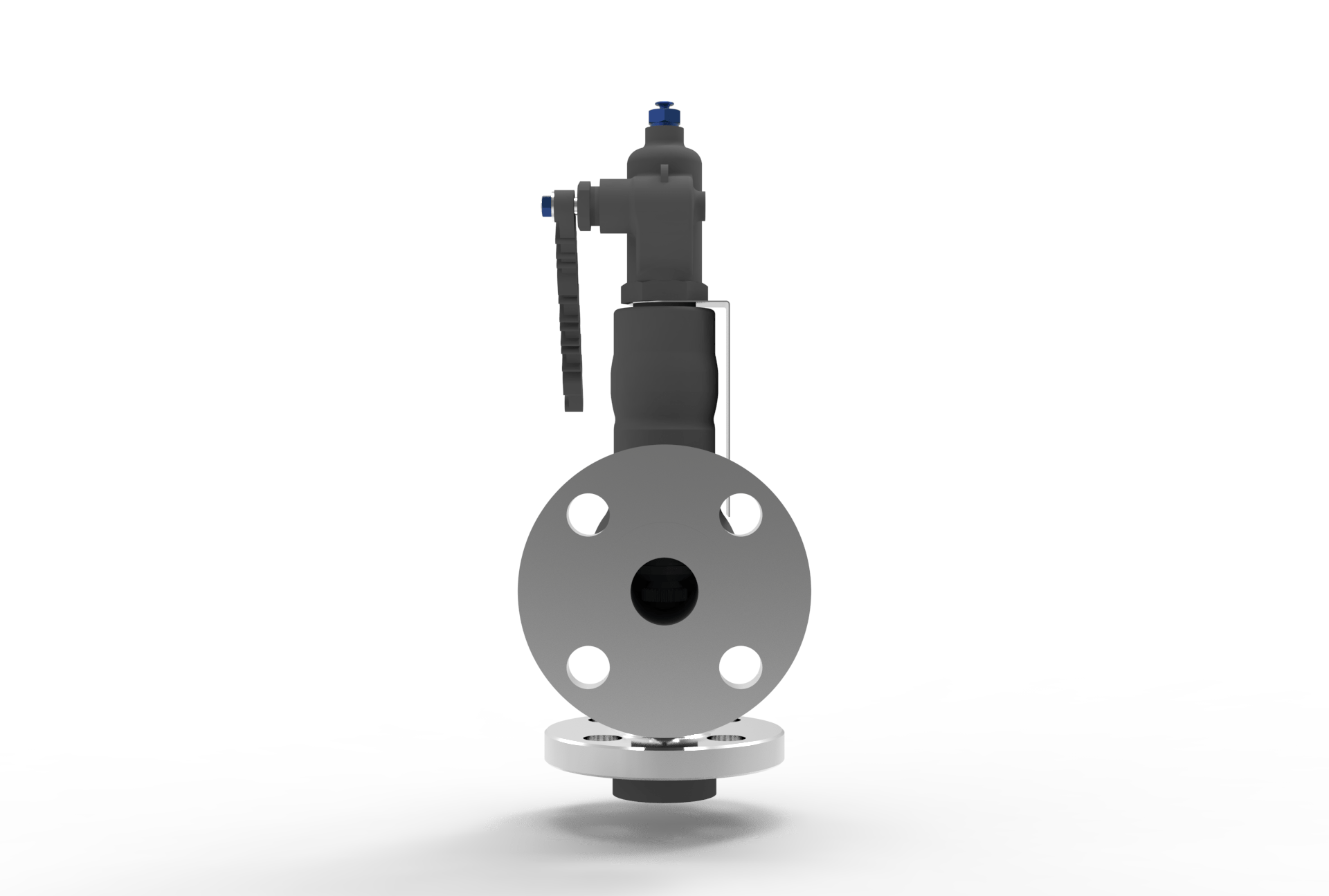

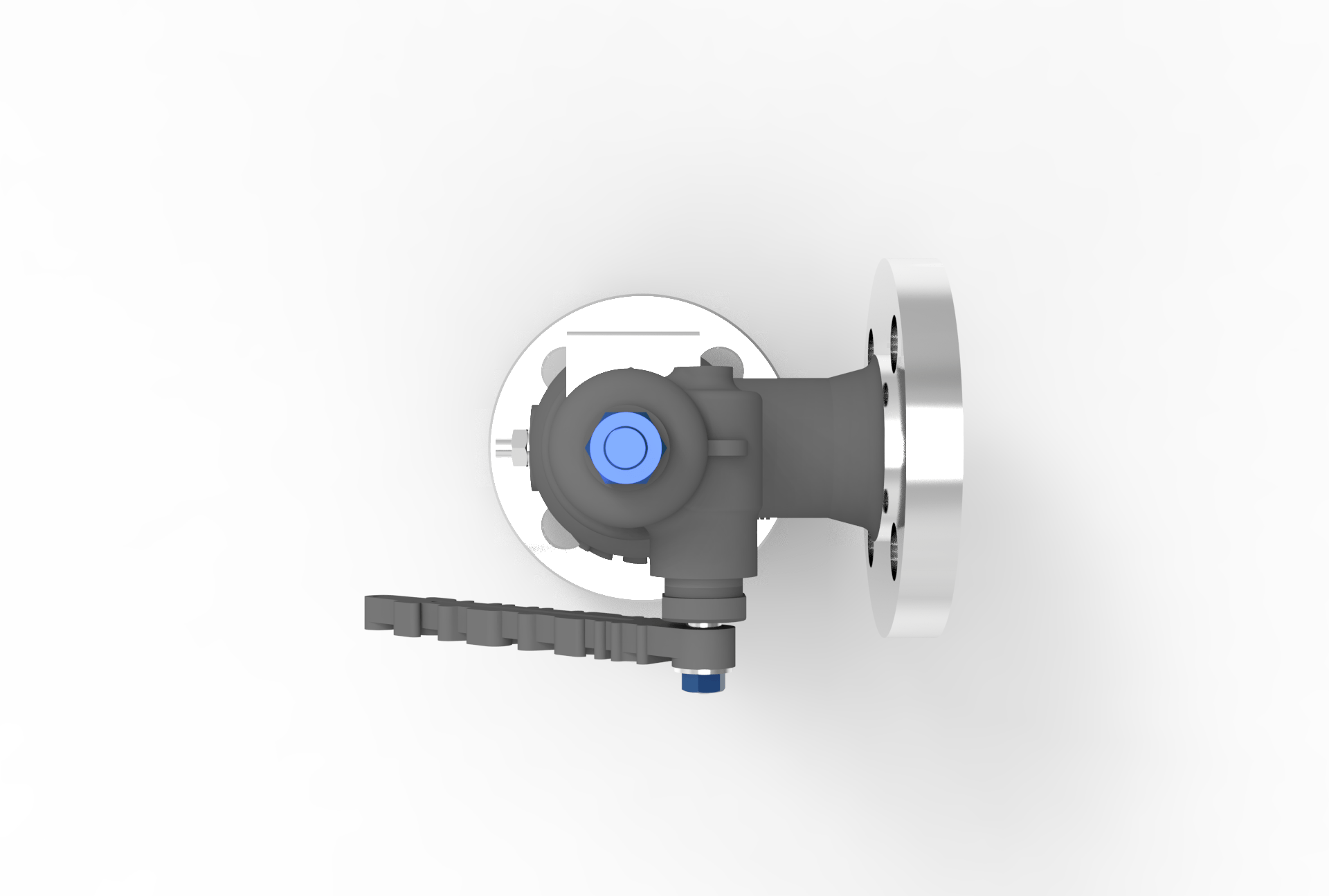

Sarasin-RSBD®

9 Series Pressure Relief Valve

The Sarasin-RSBD® safety relief valves are designed to provide high integrity performance and repeatability by their use of an integral full, one-piece nozzle, a self-aligning top-guided disc & disc-holder, and a single adjusting ring for blowdown setting. The 9 Series pressure relief valves are suitable for use within the power industry as well as for cryogenic and industrial gas processes.

KEY FEATURES & BENEFITS

-

An extensive range of material options and trim designs for varying process applications

-

Full nozzle offering protection of the valve body during its operating cycle

-

Conversion of trim designs using a minimum of components

-

Resilient seat design for maximum seat tightness and to prevent fugitive fluid emissions

-

Flow capacity tested by the US National Board and carrying the ASME UV code stamp

-

Threaded or flanged end connections

-

Block forged body design for high pressure & severe service applications

-

Suitability for NACE MR-01-75 & ISO 15156 and cryogenic applications

-

Thermal expansion process duties

SIZE RANGE & DIMENSIONS

-

15 - 40mm (0.5 - 1.5 inches)

SEAT TIGHTNESS

-

Metal seats 90% Soft seats 93%

TEMPERATURE RANGE

-

-270ºC - 400ºC (-454°F - 752°F)

MATERIALS

-

Carbon steel

-

Austenitic & Martensitic Stainless Steels

-

Duplex & Super-duplex Alloys

-

Alloy 254 (6Mo)

-

Alloy 400

-

Alloys B & C

-

Alloys 625 & 825

APPLICATIONS

-

Oil & Gas Upstream (E & P)

-

Midstream (LNG) and downstream (refining)

-

Oil & Gas pipelines & compression stations

-

Chemical & petrochemical production

-

Industrial gas (cryogenics)

-

Conventional and nuclear power plants

-

LNG & FLNG

DESIGN STANDARDS

-

ASME BPVC Section XIII

-

API Std 520

-

ISO 4126

-

PED 2014/68/UE

-

ATEX 94/9/EC

-

EAC TR CU 10/12/32

-

SELO TS

-

RCCM Codes

-

ASME BPVC Section I (Liquid Service only)

DESIGN RATINGS

-

ASME & API Class 150 to 2500 plus API Class 5000 & 10000 (customized)

CAPACITY

-

ASME Section III (St. Victoret Plant)

UPGRADES & ADAPTATIONS

-

Individually calculated and selected for each process application