Loading 3D model...

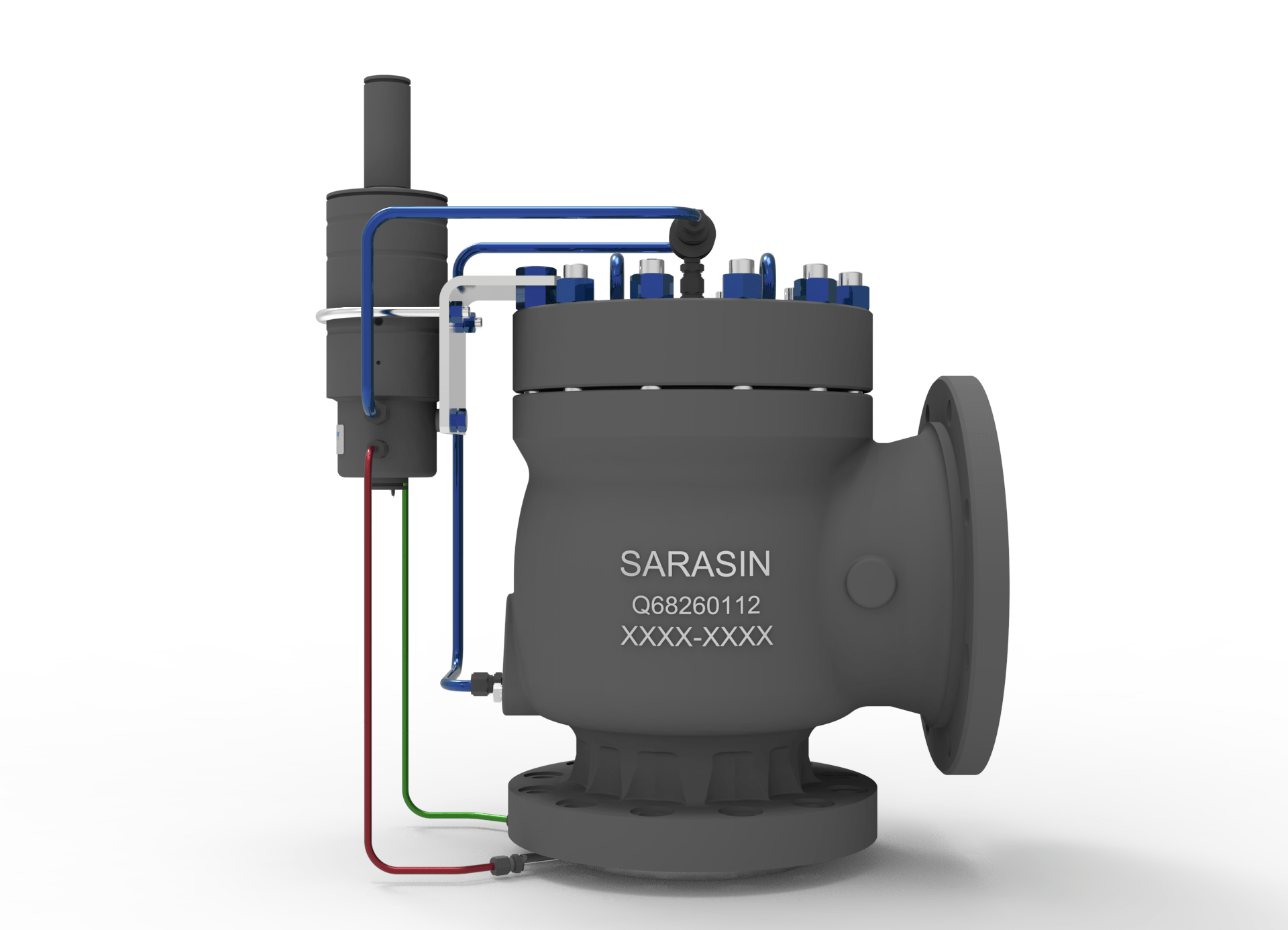

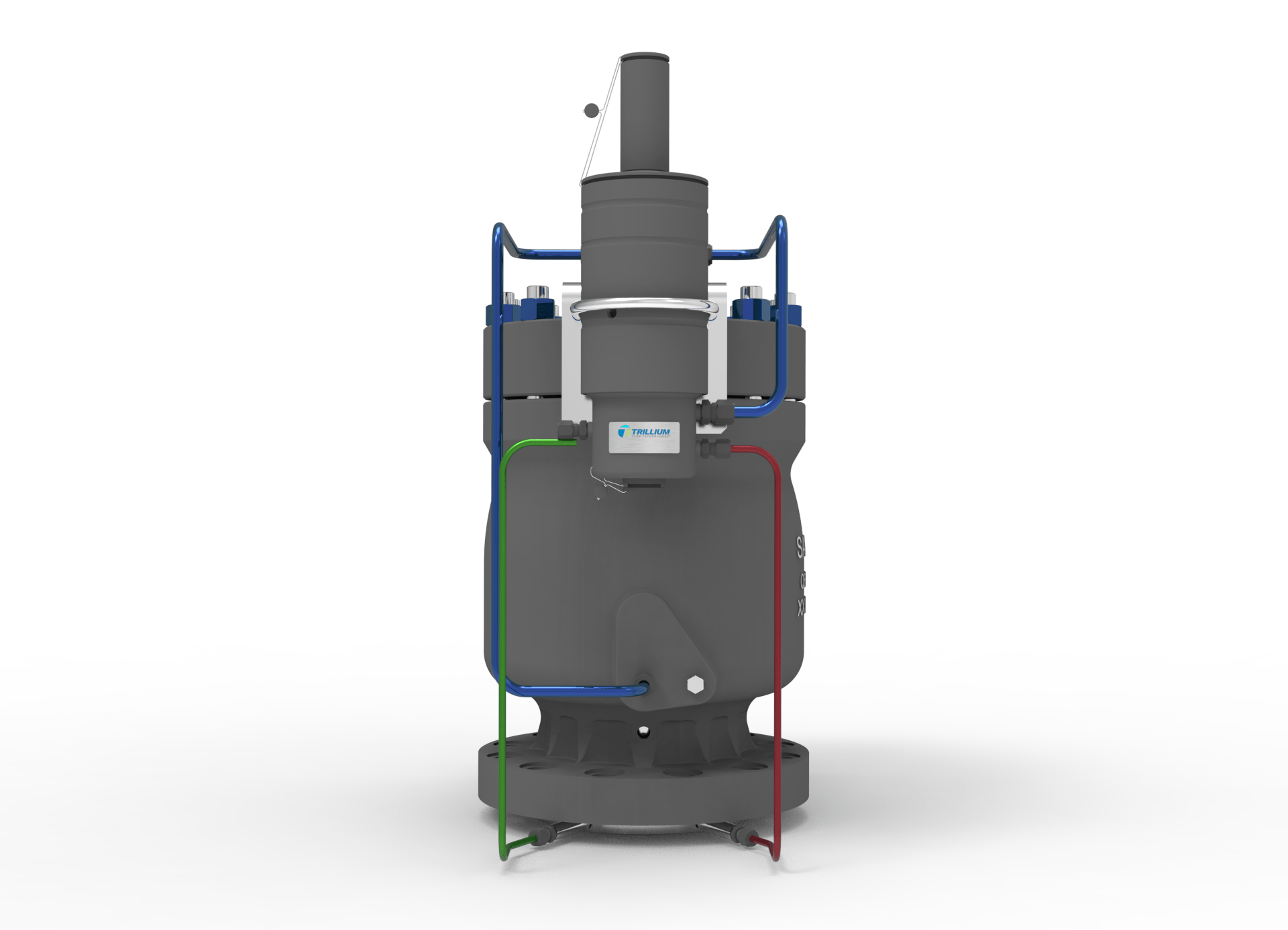

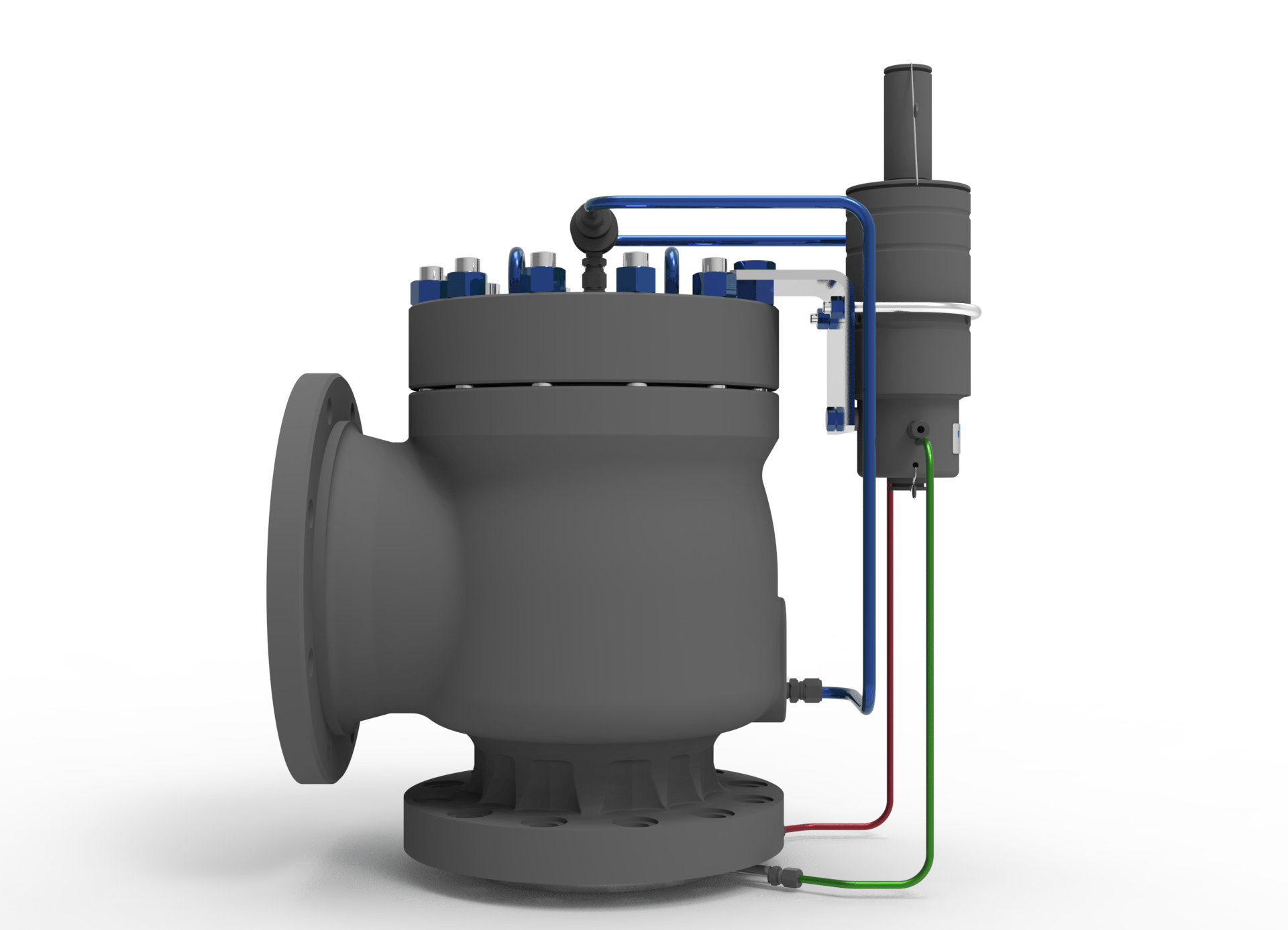

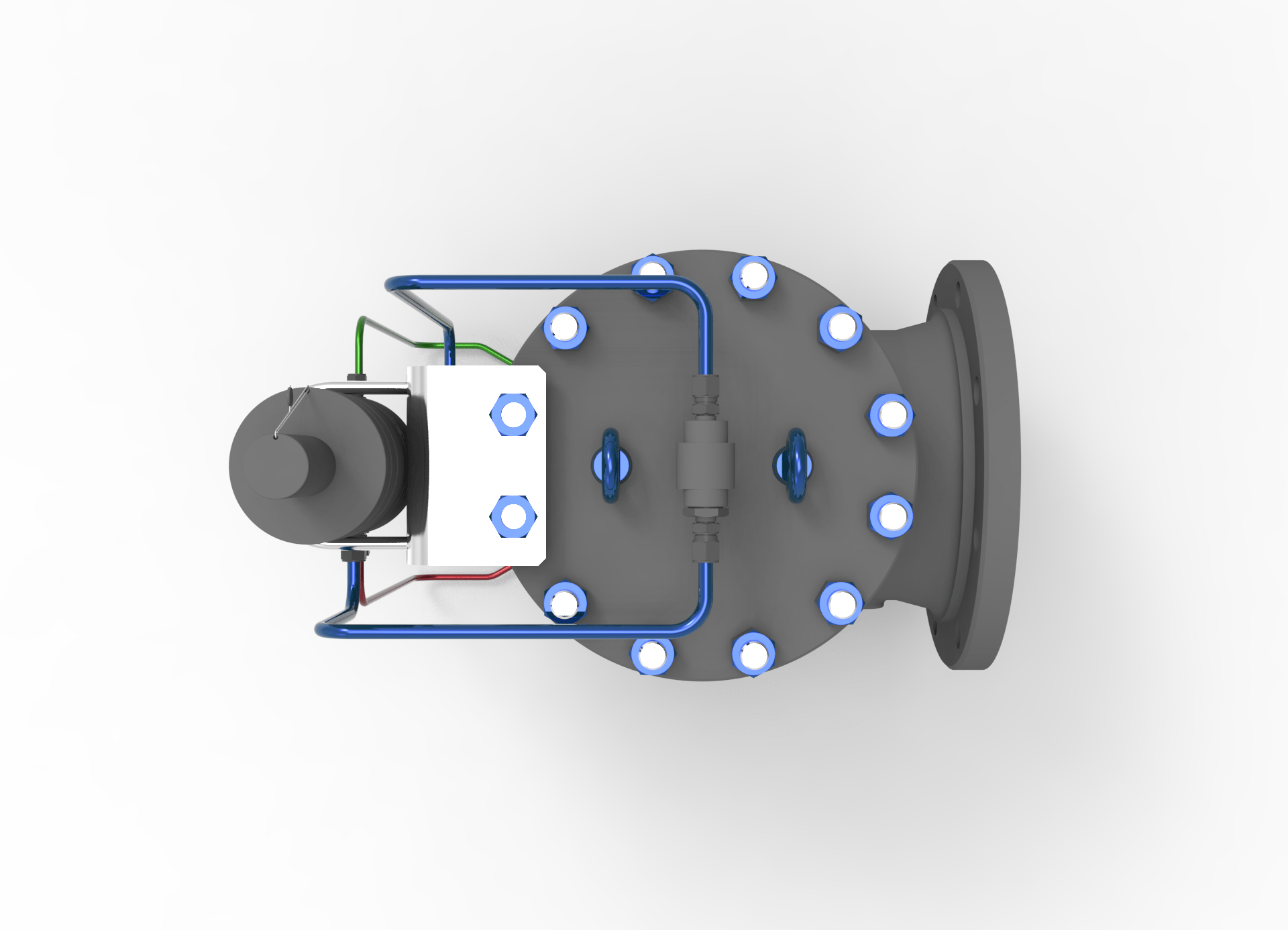

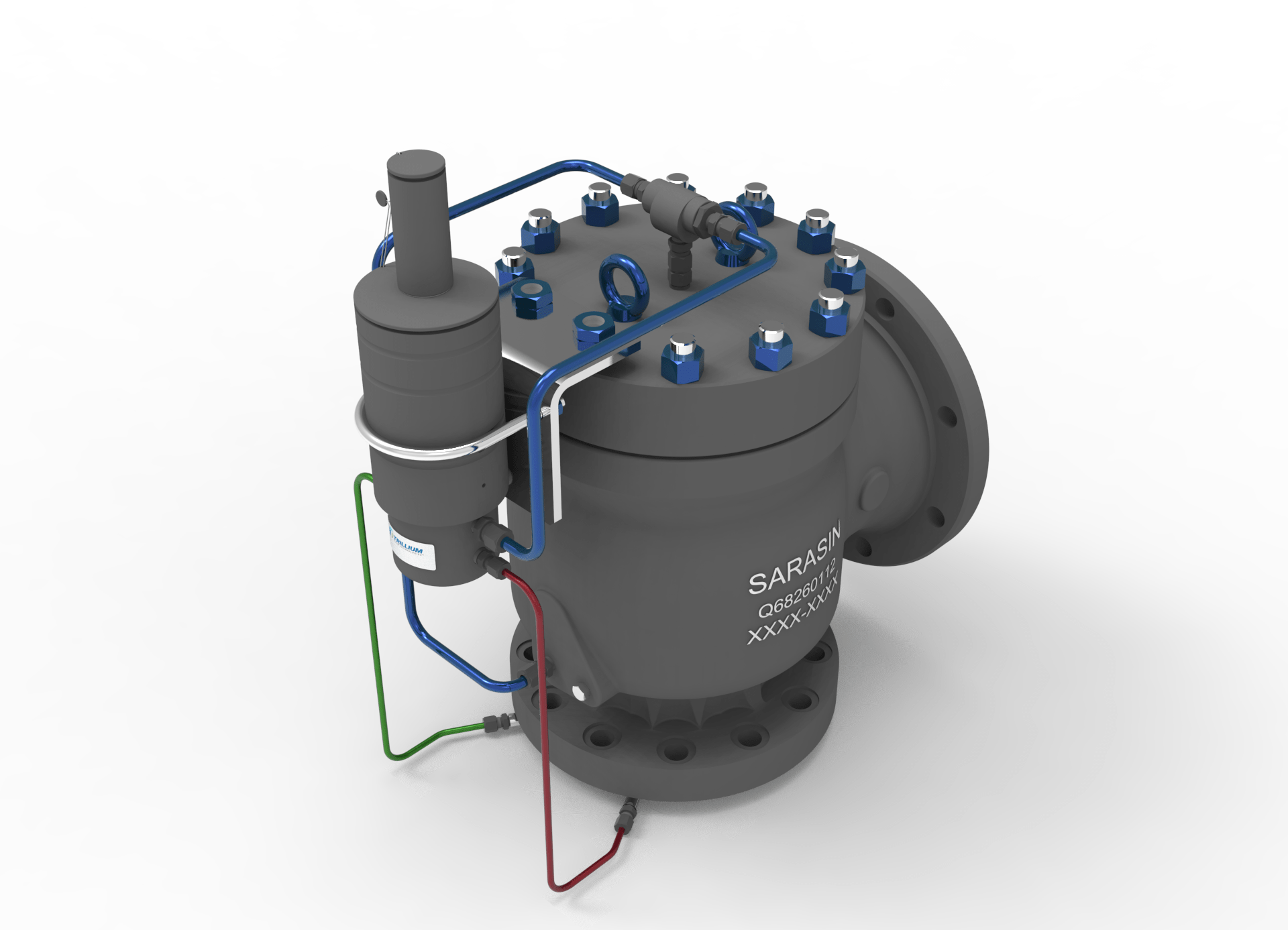

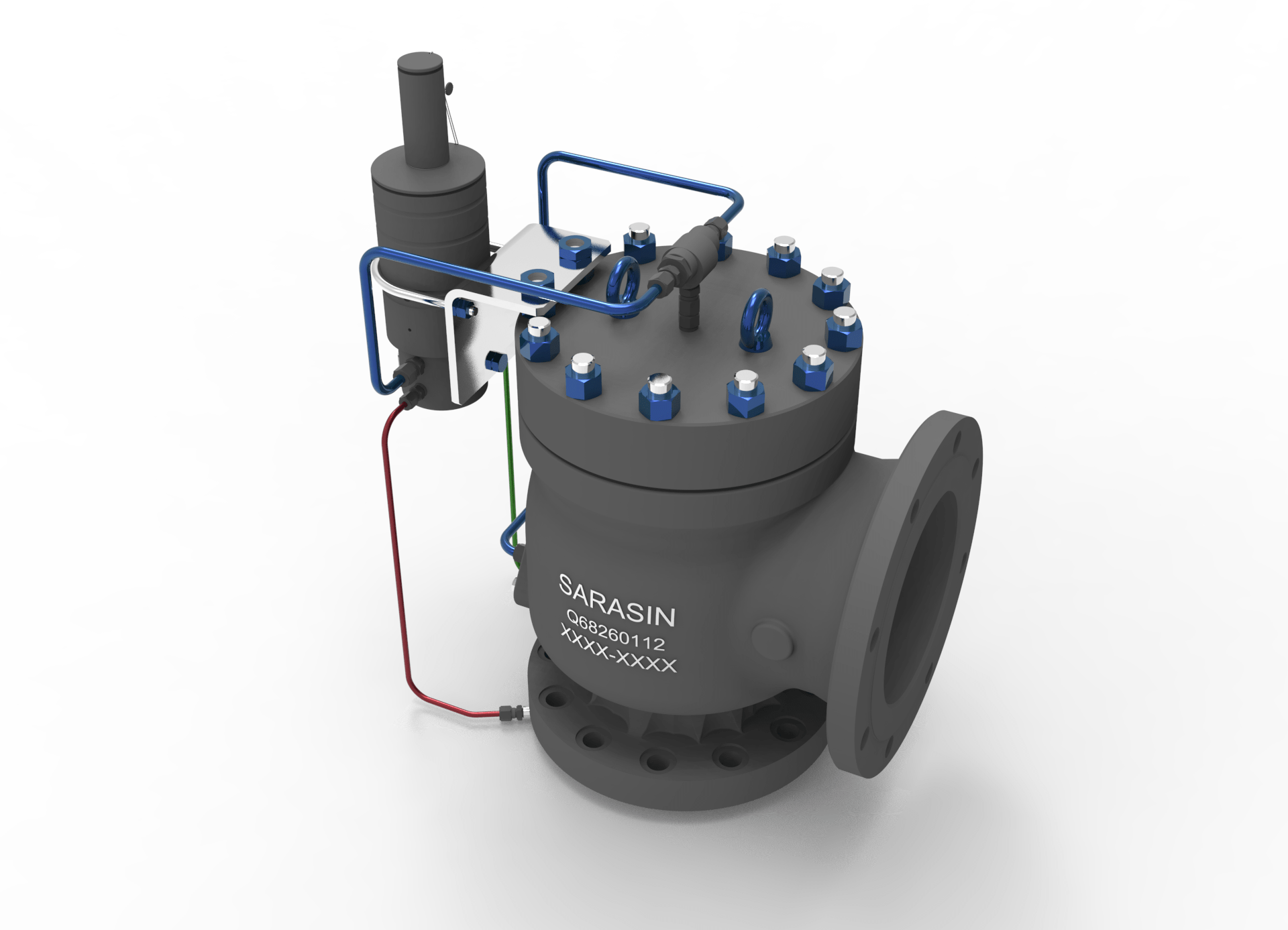

Sarasin-RSBD®

76 Series Pilot Operated Pressure Relief Valve

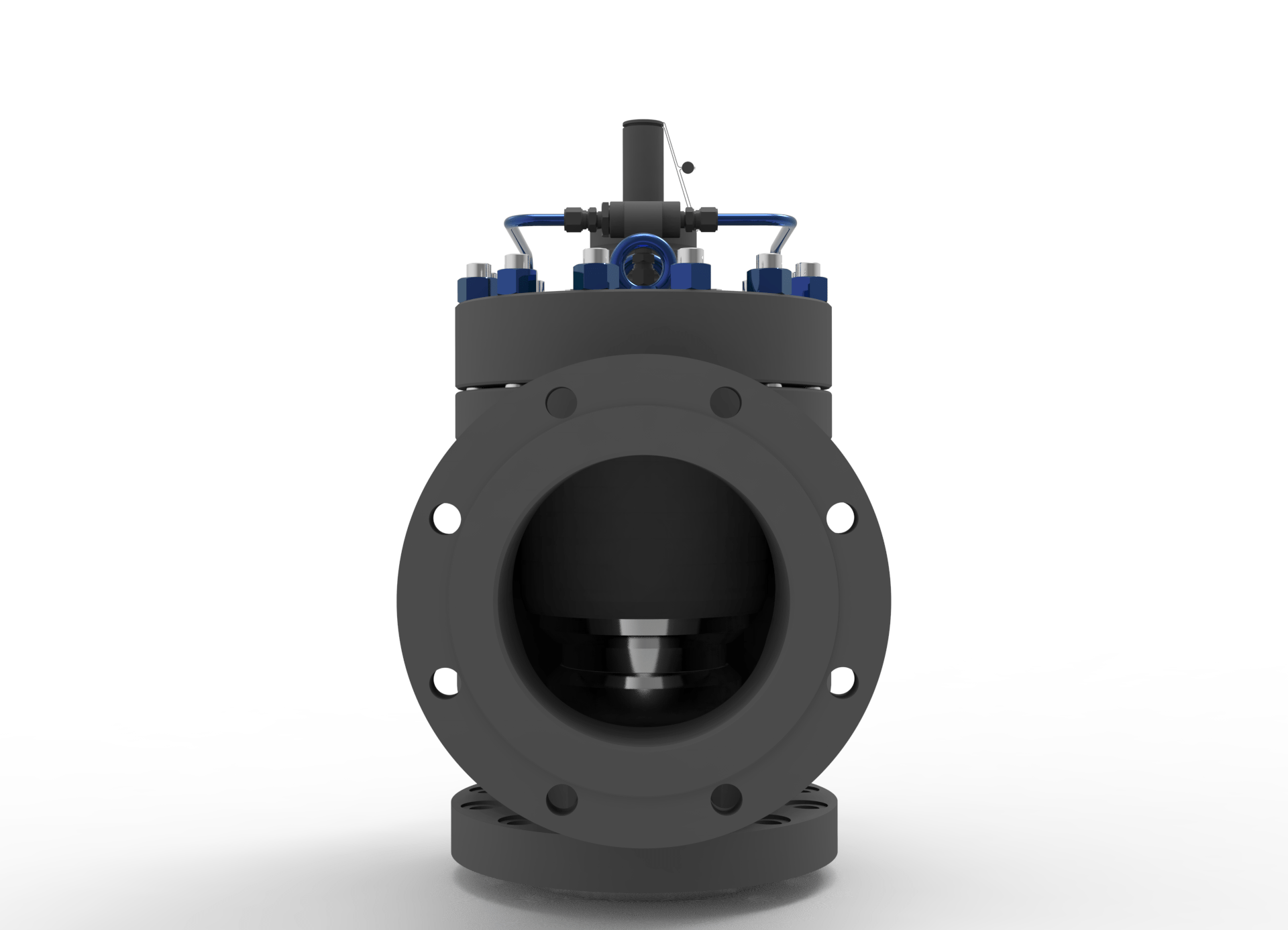

The Sarasin-RSBD® 76 Series design is based on API Standard 526 spring-loaded body design (P Series) including limited acceptable back pressure value. Therefore, the center-to-face dimensions and inlet & outlet rating meet API Standard 526 for spring-loaded valves.

In the API Standard 520 Part I, the selection of the nozzle type is only available for spring loaded pressure relief valves, not pilot operated pressure relief valves, which are designed with a semi-nozzle as a standard design.

KEY FEATURES & BENEFITS

-

An extensive range of body & pilot designs for varying process applications

-

Leak-free pop and modulating pilots

-

Avoidance of water hammer and seat chattering

-

Maximum seat tightness

-

Reduced differential between system operating pressure and valve set point

-

Capacity tested by the US National Board and carrying the ASME UV code stamp

-

Options of full nozzle and semi nozzle designs

-

API Standard 526 compliant

-

Block forged body design available for high pressure & severe service applications

-

Suitability for NACE MR-01-75 & ISO 15156 and cryogenic applications

SIZE RANGE & DIMENSIONS

-

25 - 300mm (1 -12 inches)

CAPACITY

-

Individually calculated and selected for each process application

MATERIALS

-

Carbon Steel

-

Austenitic & Martensitic Stainless Steels

-

Duplex & Super-duplex Alloys

-

Alloy 254 (6Mo)

-

Alloy 400

-

Alloys B & C

-

Alloy 625 & 825

APPLICATIONS

-

Oil & Gas; Upstream (E & P), Midstream (LNG) and downstream (refining)z

-

Oil & gas pipelines & compression stations

-

Chemical & petrochemical production

-

Conventional power plant

DESIGN STANDARDS

-

ASME BPVC Section XIII

-

API STD 520/526 (spring-loaded tables)/527

-

ISO 4126

-

Directive 2014/68/UE

-

ATEX 94/9/EC

-

EAC TR CU 10/12/32

-

SELO TS, Marine standards

-

ASME BPVC Section I (Liquid Service only)

DESIGN RATINGS

-

ASME & API Class 150 to 2500

-

API Class 5K & 10K (customized)

PRESSURE RANGE

-

Up to 431 bar (6,251 psig) with standard ASME class

TEMPERATURE RANGE

-

Reaching -196ºC (-320°F) cryogenic levels to 327ºC (620°F)

SEAT TIGHTNESS

-

95%