Loading 3D model...

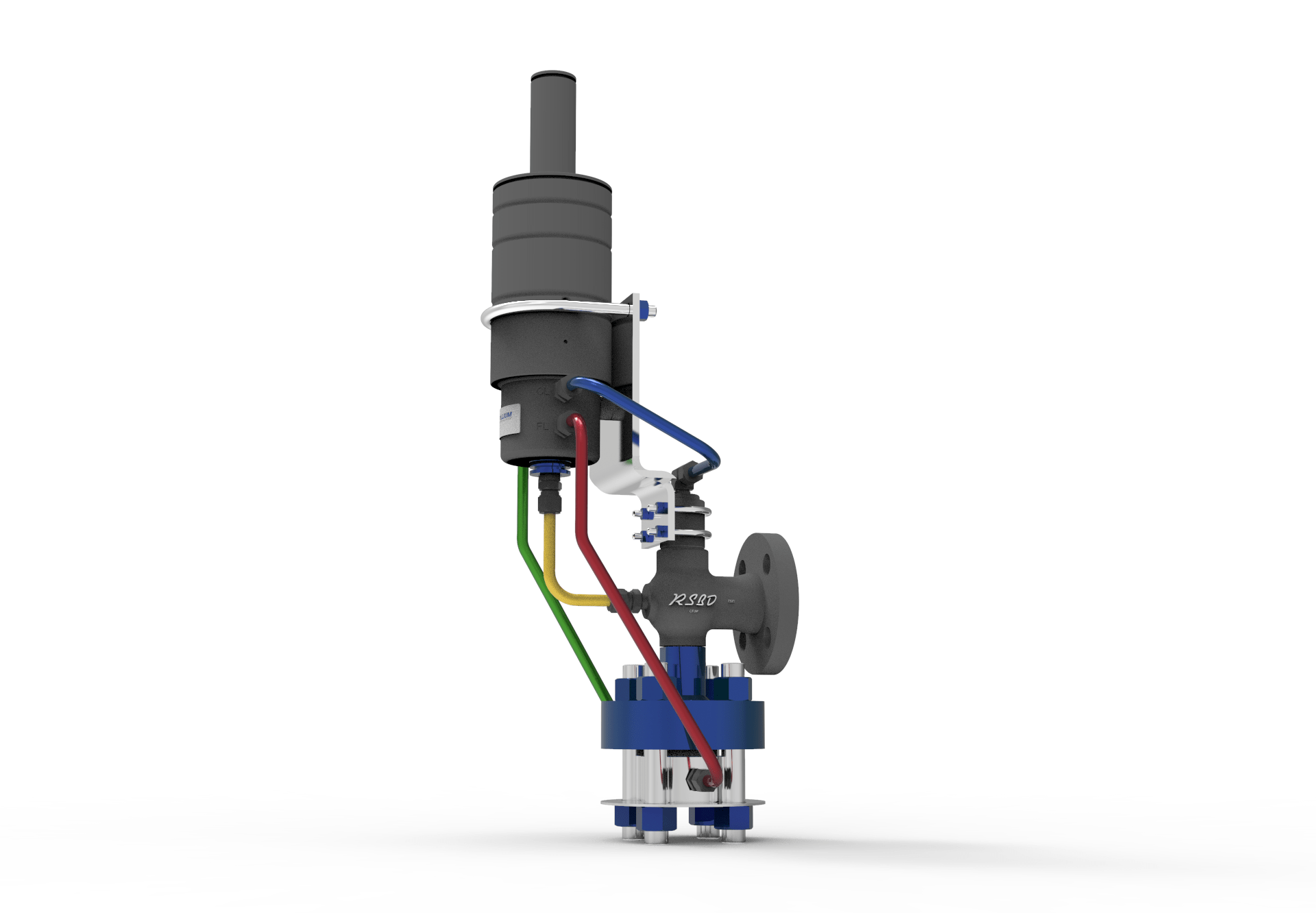

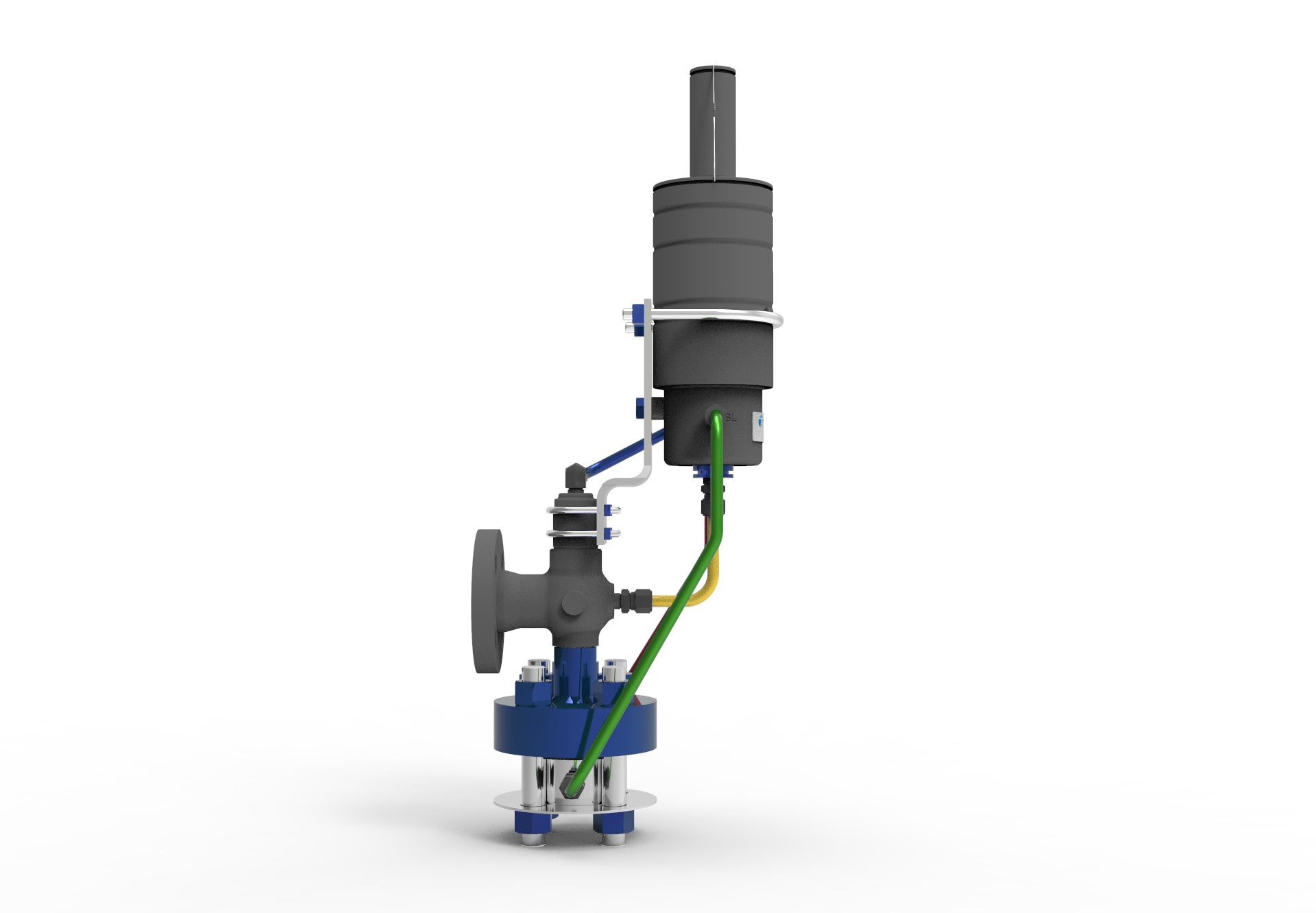

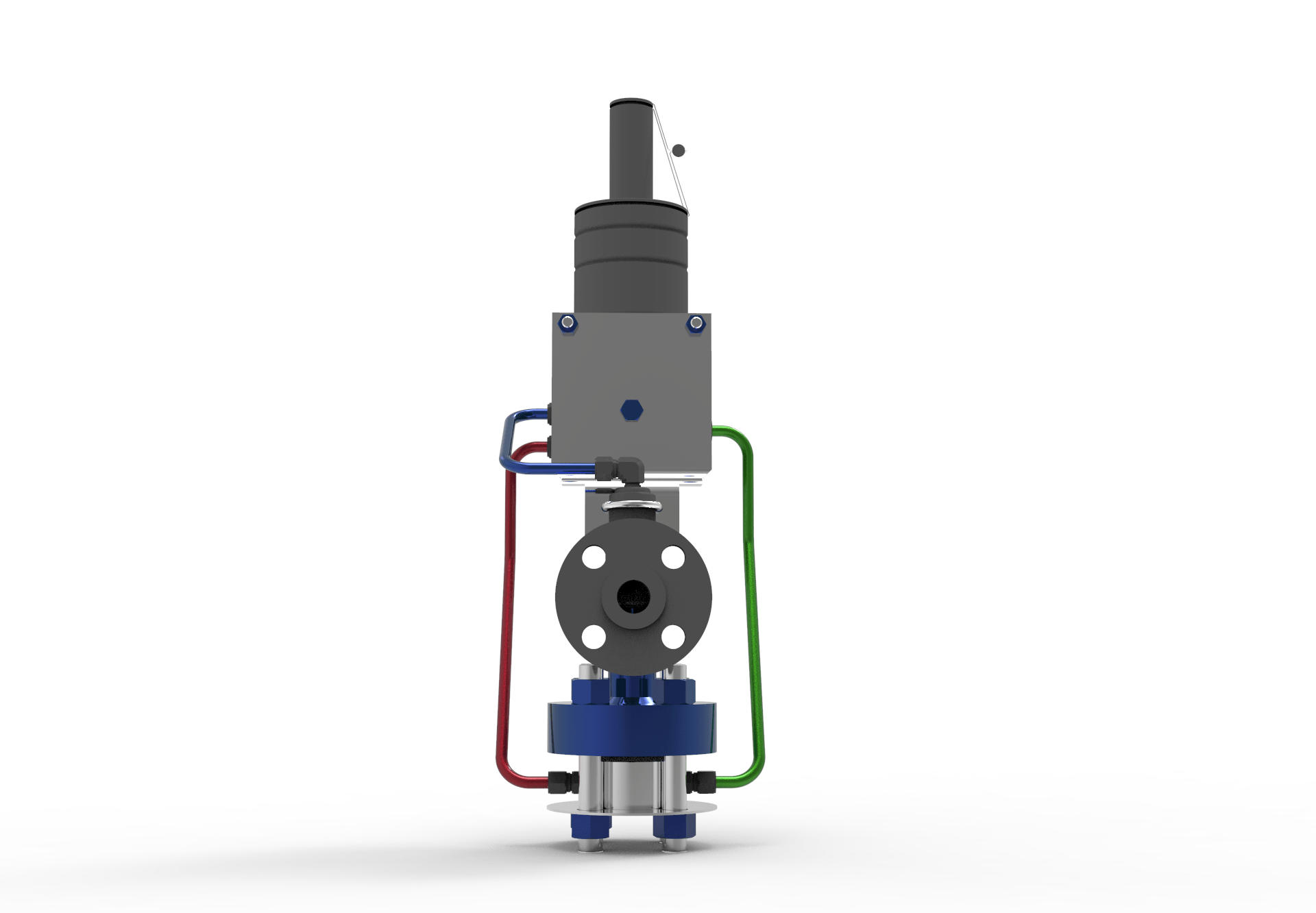

Sarasin-RSBD®

71 Series Pilot Operated Pressure Relief Valve

The Sarasin-RSBD® 71 Series design has been developed to protect the piping or vessel against thermal expansion overpressure in gas service, keeping operating pressure close to the set pressure.

The Sarasin-RSBD® 71 Series design is based on a thermal expansion spring-loaded body design (9 Series). The Sarasin-RSBD® 71 Series are an engineered, custom-made design that has been industrialized and offers a full nozzle pilot operated pressure relief valve for use in industrial gas service:

- The full nozzle option insures body chemical protection

- In case of an upgraded process (higher back pressure or higher operating pressure) the customer can change from a spring loaded to pilot operated version, keeping the same center-to-face dimension.

- The full nozzle option includes integral wetted components which offer the advantage of removal for maintenance and replacement.

The Sarasin-RSBD® 71 Series design is based on a thermal expansion spring-loaded body design (9 Series). The Sarasin-RSBD® 71 Series are an engineered, custom-made design that has been industrialized and offers a full nozzle pilot operated pressure relief valve for use in industrial gas service:

- The full nozzle option insures body chemical protection

- In case of an upgraded process (higher back pressure or higher operating pressure) the customer can change from a spring loaded to pilot operated version, keeping the same center-to-face dimension.

- The full nozzle option includes integral wetted components which offer the advantage of removal for maintenance and replacement.

DESIGN STANDARDS

-

ASME BPVC Section XIII

-

API STD 520/527

-

ISO 4126

-

Directive 2014/68/UE

-

ATEX 94/9/EC

-

EAC TR CU 10/12/32

-

SELO TS

-

Marine standards

DESIGN RATINGS

-

ASME & API Class 150 to 2500

-

API Class 5K & 10K (customized)

SIZE RANGE & DIMENSIONS

-

15 - 40mm (0.5 - 1.5 inches)

PRESSURE RANGE

-

Up to 431 bar (6,251 psig) with standard ASME class

TEMPERATURE RANGE

-

Reaching -60ºC (-76°F) cryogenic levels to 327ºC (620°F)

CAPACITY

-

Individually calculated and selected for each process application

SEAT TIGHTNESS

-

95%

MATERIALS

-

Carbon Steel

-

Austenitic Stainless Steels